يناير . 01, 2025 05:34 Back to list

Innovative Solutions for Efficient Meat Processing and Machinery Enhancements

The Evolution and Significance of Meat Machinery in the Processing Industry

In the modern meat industry, efficiency, safety, and quality control are paramount. The advent of sophisticated meat machinery has revolutionized how meat is processed, packaged, and delivered to consumers. The machinery has not only streamlined operations but also enhanced food safety and ensured compliance with regulatory standards. This article explores the various types of meat machinery, their functionalities, and their significance in the meat processing industry.

Types of Meat Machinery

The meat processing industry employs a wide range of machines and equipment that cater to different stages of meat processing. The primary categories include

1. Cutting Machines These are critical at the outset of the meat processing chain. Machines such as band saws and meat slicers facilitate the precise and efficient cutting of large meat blocks into smaller, manageable pieces. It is essential that these machines are designed for maximum hygiene and safety to prevent contamination.

2. Grinding Equipment Meat grinders are vital in the preparation of ground meats. These machines are designed to break down large cuts of meat into finer particles, which are then used in various products such as sausages and burger patties. Advanced grinding equipment often comes with adjustable settings to achieve different textures, enhancing product variety.

3. Mixing Machines After grinding, raw meat is often mixed with various seasonings and additives. Industrial mixers are used to ensure an even distribution of ingredients, essential for maintaining product consistency and flavor. High-capacity mixers help meet the demands of large-scale operations while reducing labor costs.

4. Stuffing Machines For products like sausages and hot dogs, stuffing machines are indispensable. They efficiently fill casings with mixed meat, ensuring that the product is uniform and properly sealed. This machinery significantly speeds up the production process and minimizes the risk of contamination during manual handling.

5. Cooking Equipment Once the meat is processed, cooking machines, including ovens and steamers, become crucial. These machines are designed to cook meat products to specific temperatures, ensuring they are safe for consumption while preserving their flavor and texture. Continuous cooking systems provide efficiency for large batches, reducing cooking time.

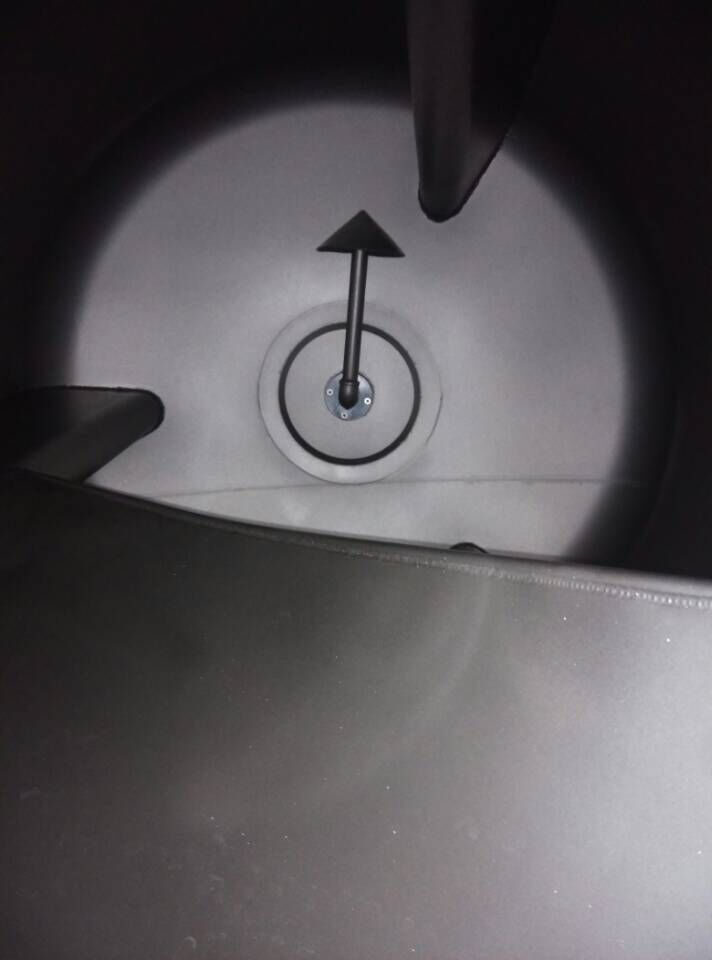

meat machinery

6. Packaging Machines The final stage of meat processing involves packaging, which is vital for preserving freshness and extending shelf life. Automated packaging machines can efficiently wrap and seal products, using materials that safeguard against contamination. Vacuum sealing is particularly popular, as it removes air and extends the life of meat products.

Significance of Meat Machinery

The modern meat processing industry relies heavily on machinery, and its significance cannot be overstated. Here are key aspects highlighting its importance

- Efficiency and Productivity Advanced meat machinery allows for rapid processing of large volumes of meat, which is essential for meeting consumer demand in a fast-paced market. Automation reduces labor costs and minimizes human error during processing, leading to increased productivity.

- Hygiene and Safety With stringent regulations around food safety, the use of dedicated machinery ensures that hygiene standards are met at every processing stage. The design of this equipment often includes features that prevent cross-contamination, making it easier to maintain a clean working environment.

- Product Quality and Consistency Consistency is crucial in the meat industry. Machinery facilitates precise cutting, grinding, and mixing, which are essential for achieving uniformity in flavor and texture across products. Customers expect high quality, and machinery helps maintain those standards.

- Innovation and Customization The continual advancement in meat machinery technology allows producers to innovate and customize their products. With advancements in automation and control systems, manufacturers can experiment with different processing methods and product formulations, responding effectively to market trends.

Conclusion

In conclusion, meat machinery plays a vital role in transforming raw meat into safe, high-quality products that meet consumer expectations. From cutting and grinding to cooking and packaging, the efficiency and reliability provided by modern equipment have reshaped the meat processing industry. As technology continues to evolve, the future of meat processing machinery promises even greater innovations, further enhancing productivity, safety, and product quality. The significance of investing in advanced meat machinery is clear for businesses aiming to thrive in a competitive marketplace.

Latest news

-

Sausage Link Cutter JC999-03: Precise, Efficient Production

NewsAug.19,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Streamline Sausage Production&Seamless Integration

NewsAug.18,2025

-

Pneumatic Clipping Machine-SHJZ Bossin|Sausage Production, Food Processing

NewsAug.18,2025

-

Pneumatic Clipping Machine-SHJZ Bossin|Sausage Production Line&Automated Clipping

NewsAug.18,2025

-

High Speed Filler-Linker-Hanger Line for Efficient Production

NewsAug.18,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Sausage Production Line, Small Meat Shop Equipment

NewsAug.17,2025