gen. . 20, 2025 09:00 Back to list

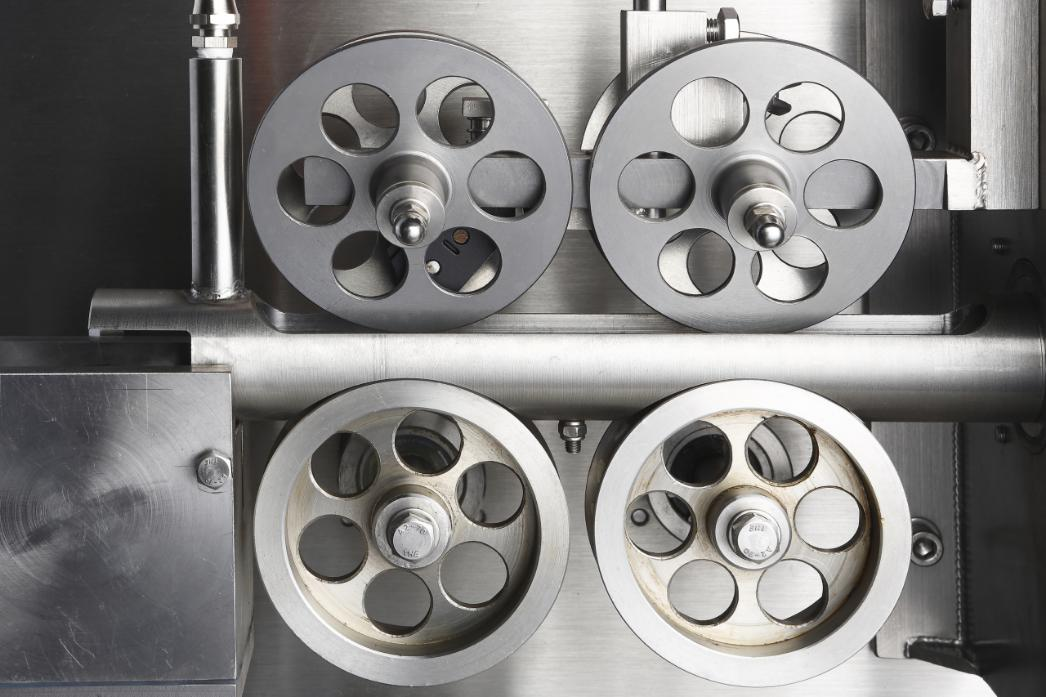

sausage binding wire machine

The sausage binding wire machine stands as an essential component in the modern manufacturing landscape of meat processing. To fully grasp its significance, one must delve into its operational mechanism, efficiency benefits, and contribution to product quality. As an individual deeply entrenched in the world of manufacturing technologies, I've witnessed the transformative impact these machines have on production lines.

Authoritativeness in the industry is often established through decades of research and development, coupled with client testimonials that attest to the improvements noted post-implementation of these machines. Many manufacturers provide comprehensive training for operators and maintenance staff, bolstering the knowledge base within the processing facility and ensuring that the equipment is used to its full potential. Trustworthiness comes from a track record of reliability and customer satisfaction. Reputable manufacturers offer robust warranties and after-sales support, ensuring that any technical issues are swiftly addressed. This commitment to customer service reassures clients that their investment is protected and that their operations will continue to run smoothly. A real-world example amplifies the value of a sausage binding wire machine. Consider a mid-sized sausage production company that faced frequent delays because of inconsistent manual binding. After adopting an automated binding wire machine, they reported not only a 30% increase in production efficiency but also significant improvements in product uniformity. This transition allowed the company to expand its market reach and solidify its reputation for quality, while also reallocating labor to more strategic roles, thus enhancing overall workplace satisfaction. In closing, sausage binding wire machines represent a critical advancement in the food processing industry. They embody the intersection of technology and productivity, offering tangible benefits that include improved efficiency, compliance with safety standards, and enhanced product quality. As consumers continue to demand higher standards in food production, and manufacturers aim to keep up with growing demands, these machines will undoubtedly remain at the forefront of innovations driving the sector forward. Their integration into production lines reflects a broader trend of embracing automation to deliver superior products efficiently and reliably.

Authoritativeness in the industry is often established through decades of research and development, coupled with client testimonials that attest to the improvements noted post-implementation of these machines. Many manufacturers provide comprehensive training for operators and maintenance staff, bolstering the knowledge base within the processing facility and ensuring that the equipment is used to its full potential. Trustworthiness comes from a track record of reliability and customer satisfaction. Reputable manufacturers offer robust warranties and after-sales support, ensuring that any technical issues are swiftly addressed. This commitment to customer service reassures clients that their investment is protected and that their operations will continue to run smoothly. A real-world example amplifies the value of a sausage binding wire machine. Consider a mid-sized sausage production company that faced frequent delays because of inconsistent manual binding. After adopting an automated binding wire machine, they reported not only a 30% increase in production efficiency but also significant improvements in product uniformity. This transition allowed the company to expand its market reach and solidify its reputation for quality, while also reallocating labor to more strategic roles, thus enhancing overall workplace satisfaction. In closing, sausage binding wire machines represent a critical advancement in the food processing industry. They embody the intersection of technology and productivity, offering tangible benefits that include improved efficiency, compliance with safety standards, and enhanced product quality. As consumers continue to demand higher standards in food production, and manufacturers aim to keep up with growing demands, these machines will undoubtedly remain at the forefront of innovations driving the sector forward. Their integration into production lines reflects a broader trend of embracing automation to deliver superior products efficiently and reliably.

Next:

Latest news

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Efficiency

NewsAug.16,2025

-

Commercial Sausage Smokehouse for Perfect Flavor & Curing

NewsAug.16,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin|Precision&Efficiency

NewsAug.16,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Precision, Efficiency, Hygiene

NewsAug.15,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Efficient Sausage Production&Cost-Effective Solution

NewsAug.15,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Automated Clipping, Precision Efficiency

NewsAug.15,2025