មករា . 02, 2025 06:10 Back to list

automatic sausage production line manufacturer

The Future of Food Manufacturing Automatic Sausage Production Line

In the ever-evolving landscape of food production, efficiency, consistency, and quality are paramount. Among the various food processing sectors, the sausage production industry has seen significant advancements with the introduction of automatic sausage production lines. These state-of-the-art systems are revolutionizing the way sausages are produced, ensuring high standards of hygiene, taste, and profitability for manufacturers worldwide.

Understanding Automatic Sausage Production Lines

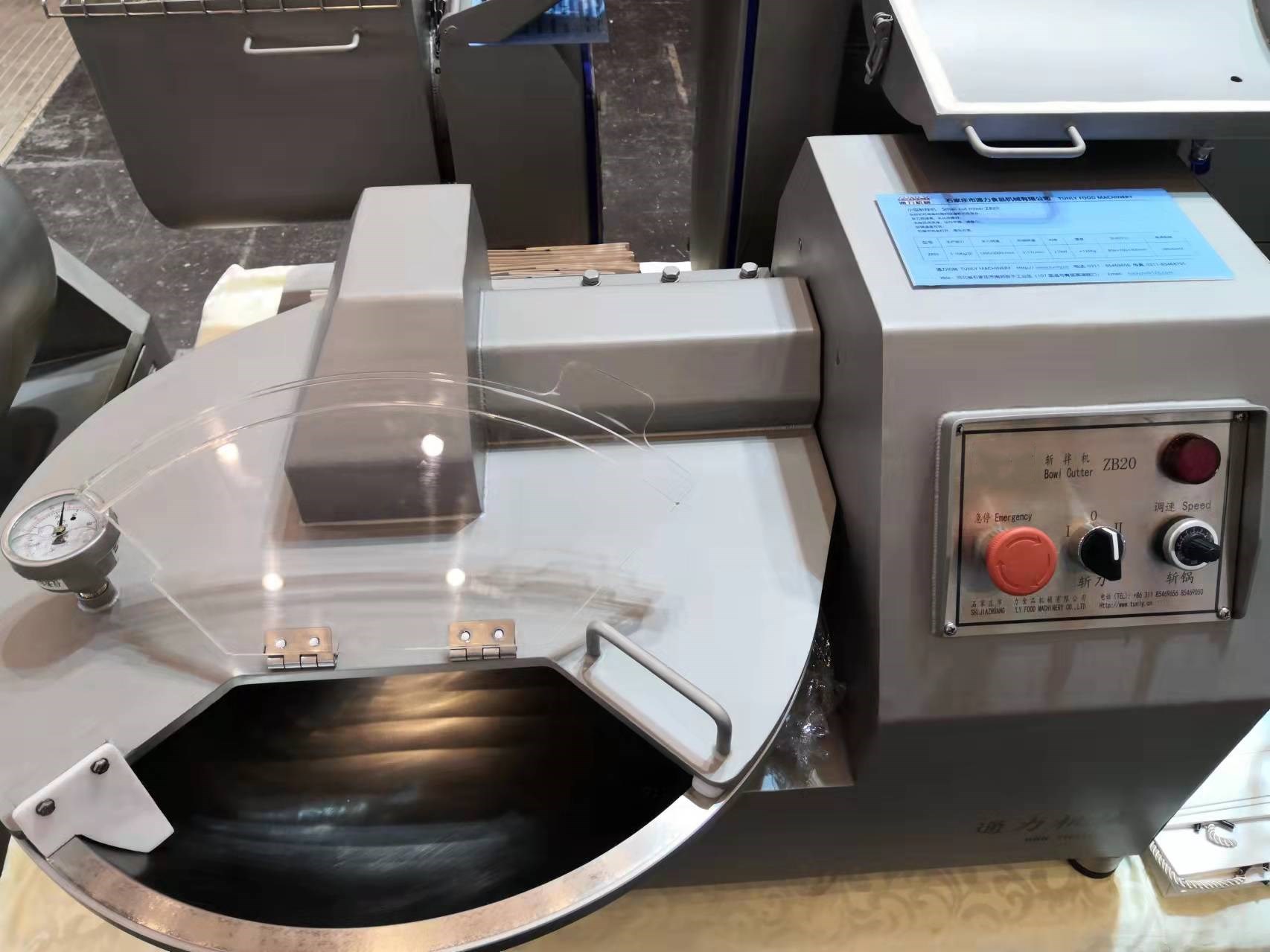

An automatic sausage production line encompasses a series of interconnected machines and equipment designed to streamline the production process, from meat preparation to packaging. When fully operational, these lines can produce thousands of sausages per hour, significantly reducing labor costs and maximizing output. The key components of such a system include meat grinders, mixers, stuffers, links, and packaging machines, all working in harmony to create a seamless production flow.

Components and Functionality

1. Meat Preparation The process begins with the selection and preparation of meat. Automatic grinders ensure that the meat is minced to the desired texture, while advanced mixing machines can incorporate spices, herbs, and other ingredients efficiently. This phase guarantees that the flavor profile is consistent across every batch produced.

2. Sausage Stuffing Once the mixture is ready, it moves to the stuffing machine. Automatic stuffers are designed to fill casings with the meat mixture at optimal speeds, ensuring even distribution and minimizing waste. The technology used in these machines provides precision, reducing the risk of air pockets that can affect the quality of the sausage.

3. Linking and Twisting After stuffing, the sausages are linked together in uniform lengths. Automatic linking machines employ innovative mechanisms for twisting and tying sausages, making the process quick and error-free. This not only enhances presentation but also aids in the cooking and smoking processes that follow.

4. Cooking and Smoking A critical step in sausage production is the cooking and smoking process. Automatic lines can incorporate ovens and smokehouses that control temperature and humidity, ensuring that each sausage is cooked to perfection and infused with just the right amount of flavor.

automatic sausage production line manufacturer

5. Packaging Finally, the fully cooked sausages are moved to automated packaging stations where they are sealed, labeled, and prepared for distribution. With the integration of vacuum sealing and gas flushing technologies, manufacturers can extend the shelf life of their products significantly while maintaining freshness.

Benefits of Automation

The integration of automatic sausage production lines offers numerous advantages over traditional methods. First and foremost, automation leads to increased production speed, allowing companies to meet rising consumer demand without sacrificing quality. Additionally, these systems reduce labor costs, as fewer workers are needed to oversee the machinery, thus allowing staff to focus on quality control and other crucial tasks.

Moreover, the consistency achieved through automation helps to establish brand trust. Consumers expect uniformity in taste and texture; automated systems excel in delivering these expectations. Furthermore, the heightened hygiene standards built into these production lines help mitigate food safety risks, ensuring that products comply with stringent health regulations.

A Step Towards Sustainability

With growing concerns over environmental impact and sustainability, the design of modern sausage production lines is increasingly focusing on eco-friendly practices. Manufacturers are incorporating energy-efficient technologies and methods to minimize waste and reduce their carbon footprint, aligning with consumer preferences for sustainable food production.

Conclusion

In conclusion, automatic sausage production lines represent a significant advancement in the food manufacturing sector. As technology continues to evolve, these systems will play a crucial role in meeting the demands of a growing global market while enhancing quality, efficiency, and sustainability. For manufacturers looking to stay competitive, investing in automation is no longer a choice but a necessity, paving the way for a more productive and innovative future in sausage production.

Latest news

-

Sausage Link Cutter JC999-03: Precise, Efficient Production

NewsAug.19,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Streamline Sausage Production&Seamless Integration

NewsAug.18,2025

-

Pneumatic Clipping Machine-SHJZ Bossin|Sausage Production, Food Processing

NewsAug.18,2025

-

Pneumatic Clipping Machine-SHJZ Bossin|Sausage Production Line&Automated Clipping

NewsAug.18,2025

-

High Speed Filler-Linker-Hanger Line for Efficient Production

NewsAug.18,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Sausage Production Line, Small Meat Shop Equipment

NewsAug.17,2025