Dec . 13, 2024 17:05 Back to list

hamburger patty forming machine

The Evolution and Importance of Hamburger Patty Forming Machines

In the realm of food processing and production, the hamburger patty forming machine serves as a quintessential piece of equipment that significantly enhances efficiency and consistency. As the demand for hamburgers continues to rise globally—whether in fast-food restaurants, casual dining establishments, or even home kitchens—the need for a reliable, efficient, and accurate method of producing hamburger patties has become essential. This article explores the evolution, functionality, and significance of hamburger patty forming machines in the modern food industry.

Historical Context

The origins of the hamburger can be traced back to the 19th century, but it wasn't until the 20th century that the hamburger became a staple of American cuisine. With the growth of fast-food chains in the 1950s, the demand for quick, mass-produced food surged. This necessitated the development of efficient machines that could rapidly produce uniform patties. Early machines were rudimentary, relying on manual work and simple mechanisms.

As technology advanced, so did the hamburger patty forming machine. The introduction of automated systems marked a turning point—these machines could produce hundreds, if not thousands, of patties in an hour. Today’s modern machines boast features such as adjustable thickness, weight control, and the ability to incorporate various ingredients, catering to the evolving palate of consumers.

How Hamburger Patty Forming Machines Work

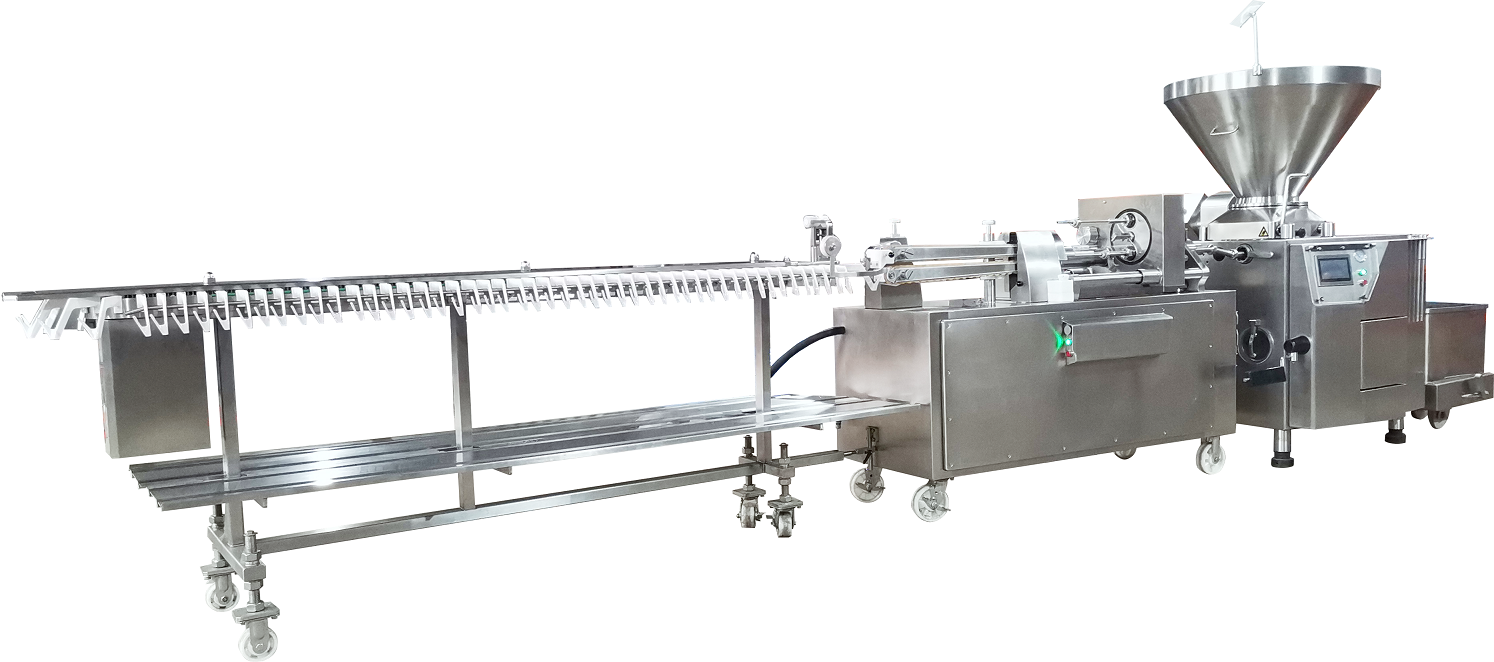

Modern patty forming machines operate using a combination of mechanical and electronic systems. The process generally begins with the input of ground meat, which is fed into a hopper where it is portioned into specific weights. The meat is then shaped into patties using one of several techniques, including

1. Molding The machine utilizes molds to create patties with consistent shapes and sizes. This method is common for producing frozen patties that require long shelf life.

2. Extrusion In some designs, the meat is extruded through a nozzle that shapes the patties as it’s dispensed. This method allows for creative shapes and customized sizes, appealing to niche markets.

hamburger patty forming machine

3. Compression Some machines use a compression technique that not only shapes the patty but also creates a perfectly uniform thickness, ensuring even cooking.

These machines often include features such as cutting and stacking mechanisms, which enhance operational efficiency and reduce the need for manual handling. Advanced patty forming machines may also incorporate systems for adding ingredients like breadcrumbs or seasonings, further customizing the product for specific consumer tastes.

The Significance of Hamburger Patty Forming Machines

The impact of these machines extends beyond mere efficiency. With the increasing demand for high-quality food products, consistency has become paramount. Consumers expect their hamburgers to have a uniform taste and texture, which is made possible through the use of patty forming machines. This consistency helps brands maintain their reputation and encourages repeat business.

Moreover, the automation of the patty-making process enhances food safety. By minimizing manual handling, the risk of contamination is significantly reduced—an essential factor in an industry increasingly scrutinized for food safety practices.

In today’s fast-changing culinary landscape, where dietary preferences are diversifying, these machines allow for flexibility in production. Whether it’s plant-based patties to cater to vegans and vegetarians or gourmet options for upscale restaurants, hamburger patty forming machines can adapt to various demands, ensuring food producers remain competitive.

Conclusion

In summary, the hamburger patty forming machine is more than just a tool for shaping meat; it represents a significant advancement in food processing technology. With its evolution from simple manual systems to sophisticated automated solutions, this machinery has transformed how hamburger patties are produced. As consumer demands continue to evolve, these machines will undoubtedly play a crucial role in shaping the future of the food industry, ensuring efficiency, safety, and quality in every bite. The hamburger may seem like a simple dish, but behind its production lies an intricate interplay of technology, safety, and culinary expertise that continues to delight consumers around the world.

Latest news

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Small Meat Shop

NewsAug.29,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd. | Efficient Sausage Production & Precision Clipping

NewsAug.29,2025

-

High-Performance Bearings for Industrial & Precision Applications

NewsAug.27,2025

-

High-Performance Vanes for Pumps & Compressors | Durable & Efficient

NewsAug.26,2025

-

JC999-03 Sausage Link Cutter: High-Speed Precision Slicing

NewsAug.21,2025

-

Sausage Link Cutter JC999-03: Precise, Efficient Production

NewsAug.19,2025