Aug . 13, 2024 22:05 Back to list

Industrial Meat Dicer Manufacturing Facility Providing High-Quality Equipment for Meat Processing Solutions

The Rise of Industrial Meat Dicer Factories Revolutionizing the Meat Processing Industry

In recent years, the meat processing industry has witnessed a significant transformation, primarily driven by advancements in technology and an increasing demand for efficiency and quality. Among the innovations that have emerged, industrial meat dicer factories stand out as a crucial component in this evolution. These factories have become essential in the production of uniformly diced meat, ensuring meat products not only meet safety standards but also satisfy consumer demands for consistency and quality.

Meeting Market Demand

As consumers become more discerning about their food choices, the demand for processed meat products continues to rise. This growth has prompted meat processing facilities to seek ways to enhance productivity and maintain high standards. Industrial meat dicer factories have emerged as a solution to this challenge, providing manufacturers with the ability to quickly and effectively prepare meat for further processing, packaging, and eventual sale. With the demands of both restaurants and retail outlets, these factories help shorten the supply chain by delivering products that are ready for immediate use.

Technological Advances

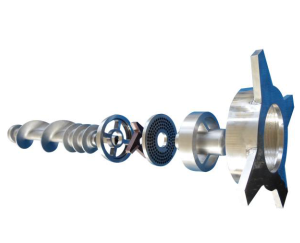

The evolution of industrial meat dicing machines has played a pivotal role in enhancing operational efficiency. Modern dicing machines are equipped with advanced features, including automation and precision cutting technology, which reduce labor costs and minimize the risk of human error. These machines can handle various types of meat, including poultry, beef, and pork, with the capability to adjust the size of the dice accordingly. With the implementation of such technology, factories are able to maintain high production rates while ensuring that the end product maintains its quality and safety.

Quality Control and Safety Standards

industrial meat dicer factory

Safety is paramount in meat processing, and industrial meat dicer factories are designed with stringent quality control measures in mind. These facilities are often compliant with national and international food safety standards, which include regular inspections and certifications. The use of automated dicing machines also helps to limit the risk of contamination, as they minimize manual handling of the meat. Additionally, many of these factories employ rigorous hygiene practices, ensuring that the dicing process is clean and that the meat is handled safely throughout the production process.

Sustainability Efforts

As the world increasingly grapples with issues related to sustainability, industrial meat dicer factories are also stepping up their game. Many facilities are adopting green practices such as energy-efficient machinery and waste reduction methods. By optimizing production lines and maximizing resource use, these factories aim to minimize their environmental footprint. Some factories are also exploring ways to utilize by-products from meat processing, incorporating these into value-added products, thereby reducing waste and promoting sustainability within the industry.

Future Trends

Looking ahead, the future of industrial meat dicer factories appears bright. Innovations in artificial intelligence and machine learning are set to further enhance production processes, allowing for even greater efficiencies and quality improvements. Moreover, as the trend towards plant-based diets grows, these factories may evolve to accommodate a wider range of products, including plant-based alternatives that require similar processing techniques.

In conclusion, industrial meat dicer factories have become a vital part of the meat processing industry, fulfilling the increasing demand for efficiency, quality, and safety. Through the implementation of advanced technology, strict adherence to food safety standards, and a commitment to sustainability, these factories are poised to play a significant role in shaping the future of meat processing for years to come. As the industry continues to evolve, the impact of these innovations on both producers and consumers will be profound, heralding a new era of meat processing.

Latest news

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Small Meat Shop

NewsAug.29,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd. | Efficient Sausage Production & Precision Clipping

NewsAug.29,2025

-

High-Performance Bearings for Industrial & Precision Applications

NewsAug.27,2025

-

High-Performance Vanes for Pumps & Compressors | Durable & Efficient

NewsAug.26,2025

-

JC999-03 Sausage Link Cutter: High-Speed Precision Slicing

NewsAug.21,2025

-

Sausage Link Cutter JC999-03: Precise, Efficient Production

NewsAug.19,2025