Aug . 14, 2024 10:14 Back to list

Suppliers of Burger Meat Breading Machines for Efficient Food Production Solutions and Equipment

Understanding the Importance of Burger Meat Breading Machines A Supplier's Perspective

In the modern fast-paced food industry, the ability to produce consistent, high-quality products is paramount. Among the numerous innovations that have transformed the food processing sector, the burger meat breading machine stands out as a critical piece of equipment for burger manufacturers. As suppliers of these machines, it's essential to understand their significance and benefits, as well as the evolving needs of the market.

The Role of Burger Meat Breading Machines

Burger meat breading machines play a vital role in the production of breaded burger patties. These specialized machines enhance the texture and flavor of meat products while also improving their visual appeal. By providing a uniform coating of breadcrumbs or batter, these machines ensure that each patty is not only delicious but also consistent in quality, making them a favorite among both consumers and food processors alike.

Efficiency and Consistency

One of the primary advantages of using a burger meat breading machine is the efficiency it introduces into the production process. Manual breading can be labor-intensive and time-consuming, often leading to discrepancies in the amount of coating applied to each patty. This can result in wasted materials and inconsistent product quality. A breading machine streamlines the process, offering automation that leads to higher throughput, reduced labor costs, and minimized waste, ultimately boosting profitability for manufacturers.

Furthermore, consistency is key in the food industry. Customers expect the same taste and texture every time they buy a product. A breading machine ensures that each burger patty receives an even coating, reducing variability and enhancing customer satisfaction. This consistency in product quality is essential for building brand loyalty in a competitive marketplace.

Customization and Versatility

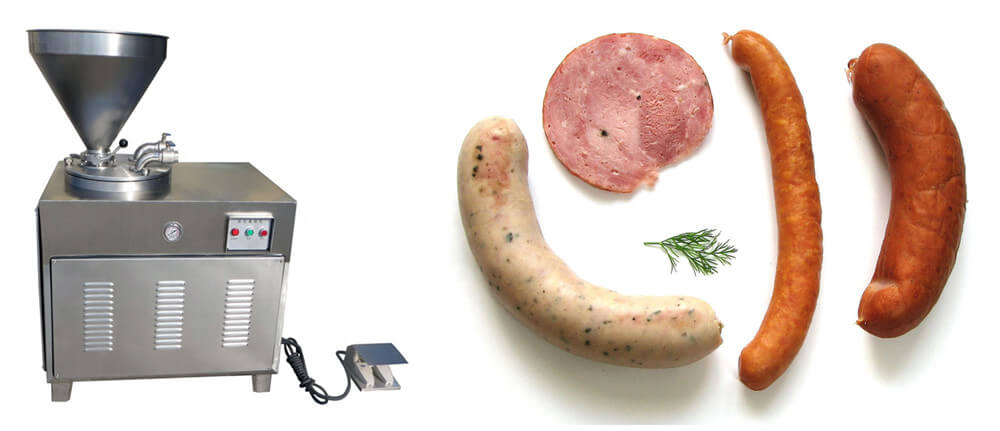

burger meat breading machine supplier

Modern burger meat breading machines offer impressive versatility, allowing manufacturers to experiment with various breading materials and coatings. Suppliers provide machines with adjustable settings for different types of breading, such as panko, seasoned breadcrumbs, or gluten-free options. This flexibility enables burger producers to cater to changing consumer demands, such as healthier options or gourmet flavors, enhancing their product line and appeal.

Moreover, the ability to easily switch between different coatings without the need for extensive cleaning between runs allows manufacturers to respond swiftly to market trends and customer preferences. This adaptability is particularly important in a food industry landscape that increasingly emphasizes innovation and variety.

Quality Assurance and Food Safety

Quality assurance is an integral part of food production, and using a burger meat breading machine contributes to maintaining high standards. Many machines come equipped with advanced technology that enhances food safety, such as ensuring proper coating adhesion and limiting cross-contamination. Suppliers of these machines often provide training and guidance regarding best practices and maintenance, further ensuring that manufacturers comply with food safety regulations.

By investing in high-quality breading machines, manufacturers can ensure that their processes are not only efficient but also aligned with the strict standards of food safety that consumers demand.

Conclusion

The role of burger meat breading machines in the food processing industry cannot be overstated. As a supplier, understanding the benefits of these machines—from efficiency and consistency to customization and quality assurance—allows you to better serve your customers and meet the dynamic needs of the market. In a world where consumers are increasingly knowledgeable about their food choices, providing advanced solutions like burger meat breading machines will not only enhance product quality but also support manufacturers in achieving operational success. Investing in such technology is a step towards remaining competitive and innovative in the bustling food industry landscape.

Latest news

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Small Meat Shop

NewsAug.29,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd. | Efficient Sausage Production & Precision Clipping

NewsAug.29,2025

-

High-Performance Bearings for Industrial & Precision Applications

NewsAug.27,2025

-

High-Performance Vanes for Pumps & Compressors | Durable & Efficient

NewsAug.26,2025

-

JC999-03 Sausage Link Cutter: High-Speed Precision Slicing

NewsAug.21,2025

-

Sausage Link Cutter JC999-03: Precise, Efficient Production

NewsAug.19,2025