Jul . 30, 2024 06:37 Back to list

Top Manufacturers of Frozen Chicken Flakers for Quality Food Processing Solutions

The Rise of Frozen Chicken Flaker Manufacturers

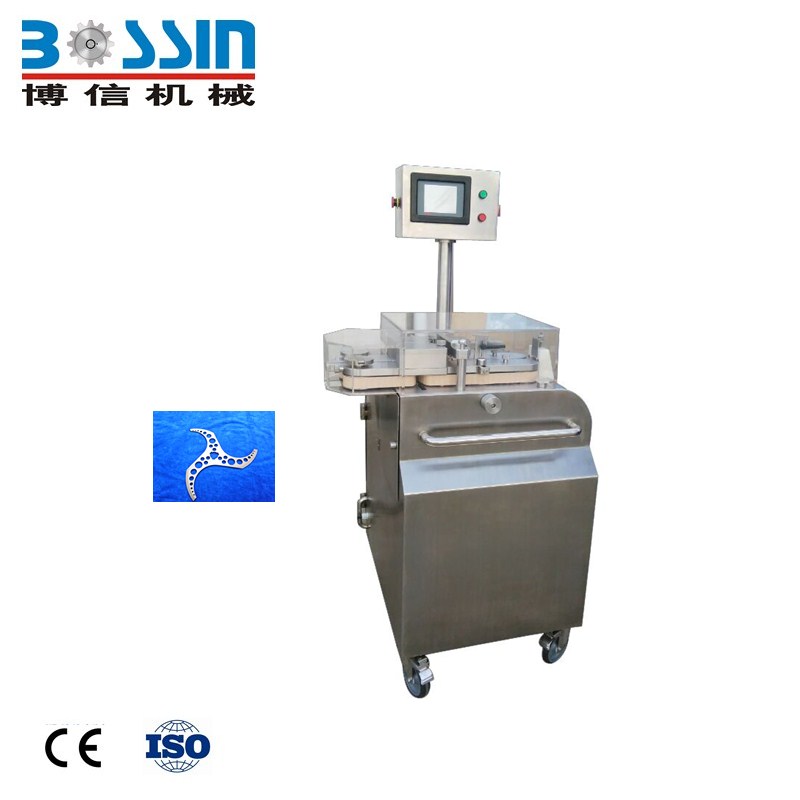

In recent years, the demand for convenient, ready-to-cook food products has surged, making frozen chicken flakers an essential item in the food industry. These specialized pieces of equipment are designed to break down frozen chicken into small, flaked pieces, ideal for various culinary applications. As the market grows, numerous frozen chicken flaker manufacturers have emerged, providing innovative solutions to meet the needs of consumers and commercial kitchens alike.

Understanding Frozen Chicken Flakers

Frozen chicken flakers are machines specifically engineered to process frozen chicken and produce uniform, shredded pieces. This flaky texture is particularly suitable for applications such as salads, sandwiches, pizzas, and casseroles. The flaking process not only improves the ease of cooking but also enhances the flavor absorption of sauces and seasonings, making it a favorite among chefs and home cooks.

The machine works by using a series of blades or drums that apply pressure to the frozen chicken, effectively separating it into flakes without compromising its texture or nutritional value. It is crucial to choose a high-quality flaker that can handle various volumes and types of chicken while maintaining hygiene and efficiency.

Key Features of Quality Flakers

When selecting a frozen chicken flaker, several key features should be considered

1. Durability A good flaker should be made of high-quality, food-grade materials that can withstand the rigors of daily use and are easy to clean.

2. Capacity Manufacturers should consider their production needs—whether they require a small, tabletop unit for a restaurant or a large industrial model for a processing facility.

frozen chicken flaker manufacturers

4. Ease of Use An intuitive design that allows for easy operation and minimal training ensures that staff can use the equipment effectively from the get-go.

5. Energy Efficiency As energy costs rise, choosing equipment that consumes less power can lead to significant savings in the long run.

The Growing Market

The frozen chicken flaker market is expected to grow significantly, driven by increasing consumer preferences for convenience foods. Factors fueling this growth include busy lifestyles, the rise of meal preparation services, and the expanding restaurant sector. Additionally, the growing awareness of food safety and hygiene has prompted manufacturers to innovate, producing machines that not only meet operational demands but also comply with stringent food safety regulations.

Countries with advanced agricultural sectors, such as the United States, Brazil, and China, are leading the charge in this market. These countries not only produce a significant amount of chicken but also have a burgeoning processed food industry that relies heavily on products like frozen chicken flakes.

Innovating for the Future

Frozen chicken flaker manufacturers are continuously innovating to keep pace with market demands. This includes the development of machines that are more efficient in terms of energy consumption and processing speed. Some manufacturers are even incorporating smart technology, allowing for real-time monitoring and adjustments, ensuring consistent product quality.

Additionally, there is a growing trend towards sustainability in the food industry. Many manufacturers are exploring eco-friendly materials and practices, from sourcing sustainable raw materials to implementing recycling programs in their production processes.

Conclusion

The frozen chicken flaker industry is witnessing a dynamic transformation, founded on the increasing demand for convenience and quality in food preparation. As consumer preferences evolve, frozen chicken flaker manufacturers must continue to innovate, focusing on durability, efficiency, and sustainability to remain competitive. With the right machinery, restaurants and food service providers can enhance their operations and satisfy the ever-growing appetite for quick and delicious meal solutions.

Latest news

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Small Meat Shop

NewsAug.29,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd. | Efficient Sausage Production & Precision Clipping

NewsAug.29,2025

-

High-Performance Bearings for Industrial & Precision Applications

NewsAug.27,2025

-

High-Performance Vanes for Pumps & Compressors | Durable & Efficient

NewsAug.26,2025

-

JC999-03 Sausage Link Cutter: High-Speed Precision Slicing

NewsAug.21,2025

-

Sausage Link Cutter JC999-03: Precise, Efficient Production

NewsAug.19,2025