ਜਨਃ . 10, 2025 08:45 Back to list

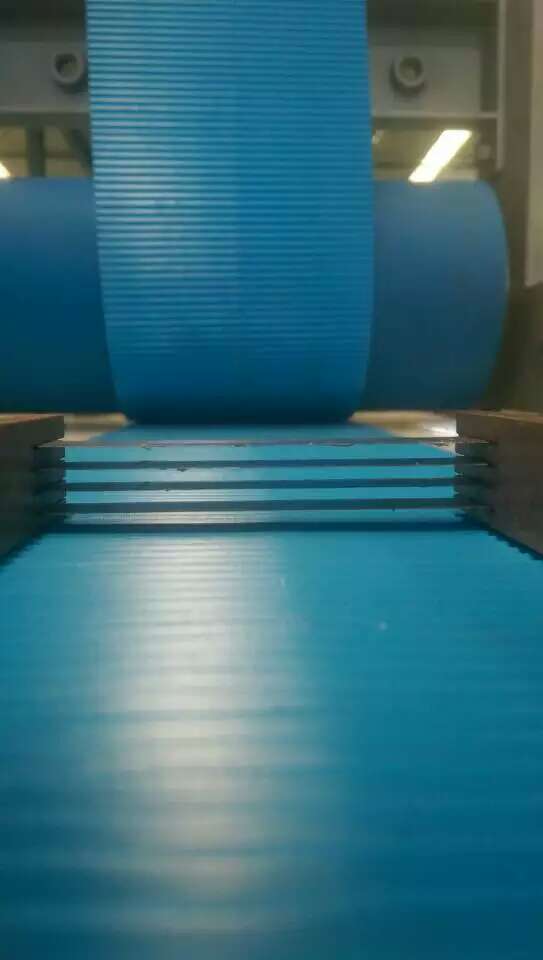

vacuum filler

Vacuum fillers are essential components in the food processing industry, known for their efficiency and reliability in filling products such as sausages, dough, and other semi-solid goods. The sophistication of these machines lies in their ability to streamline production while ensuring consistency and quality.

Trustworthiness of vacuum fillers is further reinforced by the numerous testimonials from industry veterans who attest to their reliability. These machines have been known to reduce waste significantly by consistently delivering precise portions, optimizing the profitability of production lines. Moreover, reputable brands offer extensive warranties and customer support services, boosting confidence in their products’ longevity and performance. Moreover, the contemporary vacuum filler is equipped with smart technology integration, such as IoT connectivity and data analytics, which provides actionable insights into production efficiency and maintenance needs. These innovations highlight the ongoing commitment of manufacturers to enhance the functionality and performance of vacuum fillers, ensuring they meet the ever-growing demands of the food processing industry. An investment in a vacuum filler is an investment in the future of food production. By harnessing advanced technology and adhering to the highest standards of workmanship, these machines not only improve operational efficiency but also champion the quality that consumers expect. When selecting a vacuum filler, prioritize machines that demonstrate a blend of experience-backed design, cutting-edge technology, industry authority, and reliability. This ensures not only optimal performance but also a partnership with a brand that is aligned with the values of quality and innovation. In the competitive world of food processing, a dependable vacuum filler is an indispensable ally.

Trustworthiness of vacuum fillers is further reinforced by the numerous testimonials from industry veterans who attest to their reliability. These machines have been known to reduce waste significantly by consistently delivering precise portions, optimizing the profitability of production lines. Moreover, reputable brands offer extensive warranties and customer support services, boosting confidence in their products’ longevity and performance. Moreover, the contemporary vacuum filler is equipped with smart technology integration, such as IoT connectivity and data analytics, which provides actionable insights into production efficiency and maintenance needs. These innovations highlight the ongoing commitment of manufacturers to enhance the functionality and performance of vacuum fillers, ensuring they meet the ever-growing demands of the food processing industry. An investment in a vacuum filler is an investment in the future of food production. By harnessing advanced technology and adhering to the highest standards of workmanship, these machines not only improve operational efficiency but also champion the quality that consumers expect. When selecting a vacuum filler, prioritize machines that demonstrate a blend of experience-backed design, cutting-edge technology, industry authority, and reliability. This ensures not only optimal performance but also a partnership with a brand that is aligned with the values of quality and innovation. In the competitive world of food processing, a dependable vacuum filler is an indispensable ally.

Next:

Latest news

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Streamline Sausage Production&Seamless Integration

NewsAug.18,2025

-

Pneumatic Clipping Machine-SHJZ Bossin|Sausage Production, Food Processing

NewsAug.18,2025

-

Pneumatic Clipping Machine-SHJZ Bossin|Sausage Production Line&Automated Clipping

NewsAug.18,2025

-

High Speed Filler-Linker-Hanger Line for Efficient Production

NewsAug.18,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Sausage Production Line, Small Meat Shop Equipment

NewsAug.17,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Efficiency & Precision

NewsAug.17,2025