paź . 05, 2024 21:57 Back to list

Leading Manufacturer of Innovative Meat Processing Equipment for Quality Solutions

The Rise of Meat Machine Manufacturers Transforming the Meat Processing Industry

In recent years, the meat processing industry has undergone significant transformations, largely driven by advancements in technology and a growing demand for efficiency and sustainability. At the heart of this evolution are meat machine manufacturers, who play a crucial role in developing innovative equipment and machinery designed to streamline various meat processing activities.

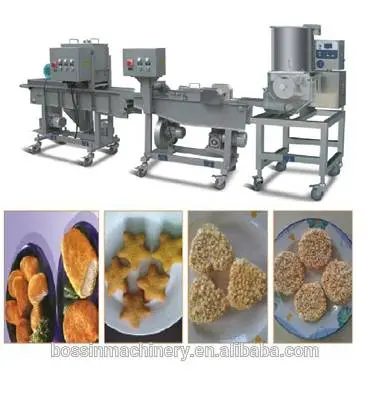

Meat machine manufacturers are responsible for producing a wide range of equipment used in the processing of meat, from cutting and grinding to packaging and preserving. These companies focus on creating advanced machinery that enhances productivity while ensuring compliance with health and safety standards. The increasing global population and the rising demand for meat products have necessitated the need for more efficient processing systems, driving innovation within the industry.

One of the key trends shaping the meat machine manufacturing sector is the push towards automation. As labor costs rise and the workforce in the food processing industry becomes more challenging to source, automation offers a viable solution. Meat processing machines equipped with cutting-edge technology can reduce the need for manual labor, increase production speed, and enhance consistency in product quality. High-tech meat machines, such as automated slicers, fillers, and packaging lines, are becoming essential components of modern meat processing facilities.

meat machine manufacturer

In addition to automation, sustainability has emerged as a pivotal focus for meat machine manufacturers. The environmental impact of meat production is a growing concern, prompting manufacturers to design machines that minimize waste and energy consumption. For instance, some machines are now engineered to optimize the use of meat cuts, reducing waste and enabling processors to utilize as much of the animal as possible. Furthermore, energy-efficient machines can help meat processors lower their carbon footprint, contributing to a more sustainable industry overall.

Moreover, meat machine manufacturers are also exploring the integration of smart technologies into their products. The rise of the Internet of Things (IoT) has opened new avenues for real-time monitoring and data analytics within processing plants. Smart machines can communicate with each other, allowing operators to track production levels, machine performance, and maintenance needs. Such data-driven insights can lead to improved operational efficiency and reduced downtime, ultimately leading to higher profitability for meat processors.

As meat machine manufacturers continue to innovate, they are also faced with the challenge of meeting diverse market needs. Consumers today are increasingly concerned about the origins of their food, animal welfare, and food safety. Manufacturers must tailor their machines to facilitate the production of specialty products, such as organic or ethically sourced meats, while also ensuring compliance with stringent food safety regulations.

In conclusion, meat machine manufacturers play an essential role in the modernization and sustainability of the meat processing industry. By focusing on automation, sustainability, and smart technologies, these companies are not only improving the efficiency of meat production but also addressing the evolving demands of consumers and regulators. As the industry continues to evolve, meat machine manufacturers will be at the forefront, driving innovation and shaping the future of meat processing.

Latest news

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Automated Clipping, Precision Efficiency

NewsAug.15,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Precision Sausage Production&Efficient Automation

NewsAug.15,2025

-

GZB80 Meat Bowl Cutter: High-Speed Precision for Emulsification

NewsAug.15,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Meat Shop Equipment

NewsAug.15,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Efficient Sausage Clipping&Seamless Integration

NewsAug.14,2025

-

Pneumatic Clipping Machine- Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Sausage Production Line&High-Accuracy Clipping

NewsAug.14,2025