Янв . 14, 2025 15:25 Back to list

Sausage Smokehouse one door two trolley

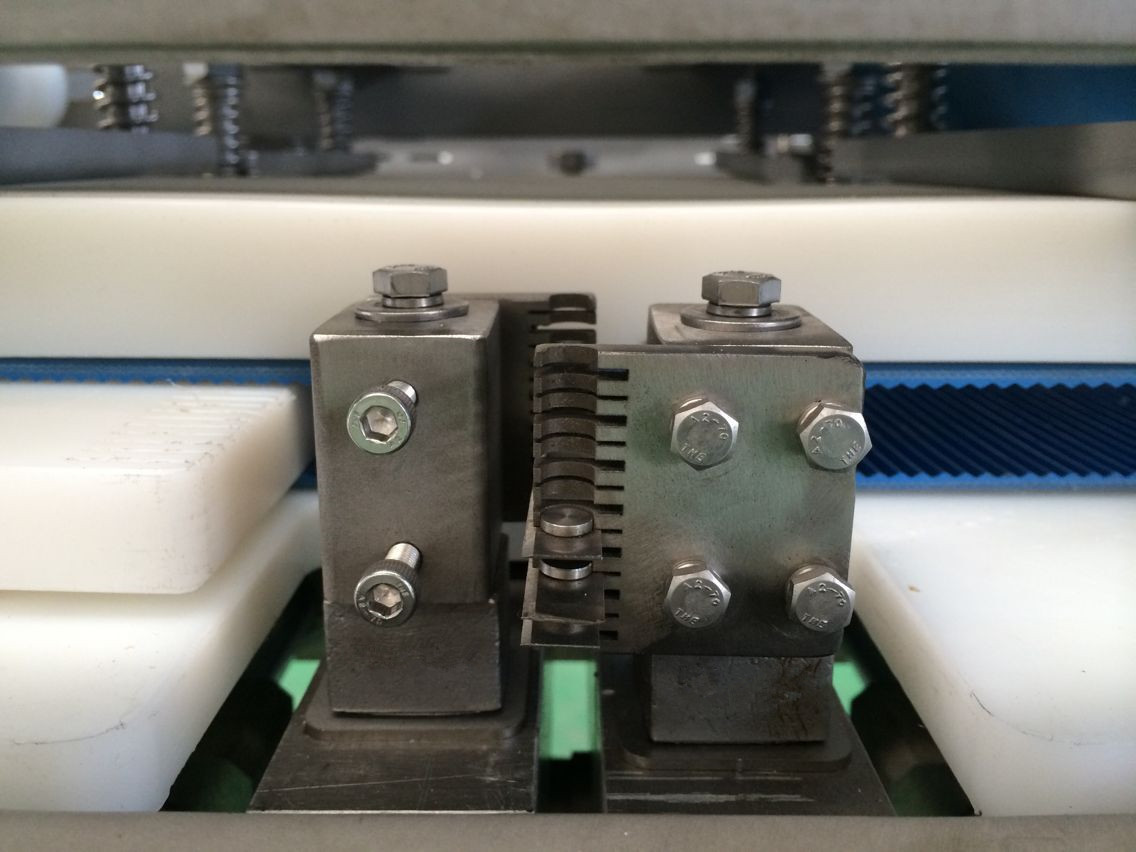

The mechanical sausage clipper machine stands as a paramount innovation in the meat processing industry, bolstering efficiency, precision, and hygiene. Businesses seeking to enhance their meat processing operations can significantly benefit from integrating this advanced technology.

Trustworthiness in the context of mechanical sausage clipper machines hinges on consistently delivering on their promises of efficiency and reliability. It's imperative that these machines undergo regular maintenance checks and are serviced by certified professionals to uphold their performance. In my experience, establishing robust maintenance schedules has not only extended the lifespan of the equipment but also reduced the likelihood of unexpected breakdowns, ensuring a smooth operation. Furthermore, investing in a mechanical sausage clipper machine can drastically reduce labor costs and increase throughput. However, it's essential to conduct a cost-benefit analysis tailored to the scale of your operations. The initial investment may seem substantial, but the long-term savings in labor and increased productivity often justify the expenditure. Additionally, ensuring that your staff is adequately trained to operate these machines will also optimize your investment. Suppliers typically offer comprehensive training sessions and support to help your team get accustomed to the machinery, reinforcing confidence in both the purchase and operation. When choosing a supplier, it's crucial to consider not only the cost but also the level of customer service and support offered, which can make a significant difference in operational efficiency. In conclusion, the adoption of a mechanical sausage clipper machine represents a substantial step forward for any meat processing entity. It promises unmatched precision, efficiency, and reliability, factors that are instrumental in maintaining competitive advantage. Embracing such technological advancements not only streamlines operations but also enhances product quality, positioning your business for greater success in the dynamic food industry landscape. As you consider integrating these machines into your setup, prioritize those that offer a blend of performance excellence, reputable manufacturer backing, and comprehensive after-sales support to ensure you're making a decision that will pay dividends in the long run.

Trustworthiness in the context of mechanical sausage clipper machines hinges on consistently delivering on their promises of efficiency and reliability. It's imperative that these machines undergo regular maintenance checks and are serviced by certified professionals to uphold their performance. In my experience, establishing robust maintenance schedules has not only extended the lifespan of the equipment but also reduced the likelihood of unexpected breakdowns, ensuring a smooth operation. Furthermore, investing in a mechanical sausage clipper machine can drastically reduce labor costs and increase throughput. However, it's essential to conduct a cost-benefit analysis tailored to the scale of your operations. The initial investment may seem substantial, but the long-term savings in labor and increased productivity often justify the expenditure. Additionally, ensuring that your staff is adequately trained to operate these machines will also optimize your investment. Suppliers typically offer comprehensive training sessions and support to help your team get accustomed to the machinery, reinforcing confidence in both the purchase and operation. When choosing a supplier, it's crucial to consider not only the cost but also the level of customer service and support offered, which can make a significant difference in operational efficiency. In conclusion, the adoption of a mechanical sausage clipper machine represents a substantial step forward for any meat processing entity. It promises unmatched precision, efficiency, and reliability, factors that are instrumental in maintaining competitive advantage. Embracing such technological advancements not only streamlines operations but also enhances product quality, positioning your business for greater success in the dynamic food industry landscape. As you consider integrating these machines into your setup, prioritize those that offer a blend of performance excellence, reputable manufacturer backing, and comprehensive after-sales support to ensure you're making a decision that will pay dividends in the long run.

Next:

Latest news

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery|Sausage Production Line,Pneumatic Technology

NewsAug.17,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Sausage Production, Automated Clipping

NewsAug.17,2025

-

High-Speed Filler-Linker-Hanger Line: Boost Production

NewsAug.17,2025

-

Pneumatic Clipping Machine- Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Sausage Production Line&Pneumatic System

NewsAug.17,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Automated Sausage Production&Precision Clipping Technology

NewsAug.16,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Efficiency

NewsAug.16,2025