jan . 13, 2025 16:28 Back to list

Meat bowl cutter GZB80

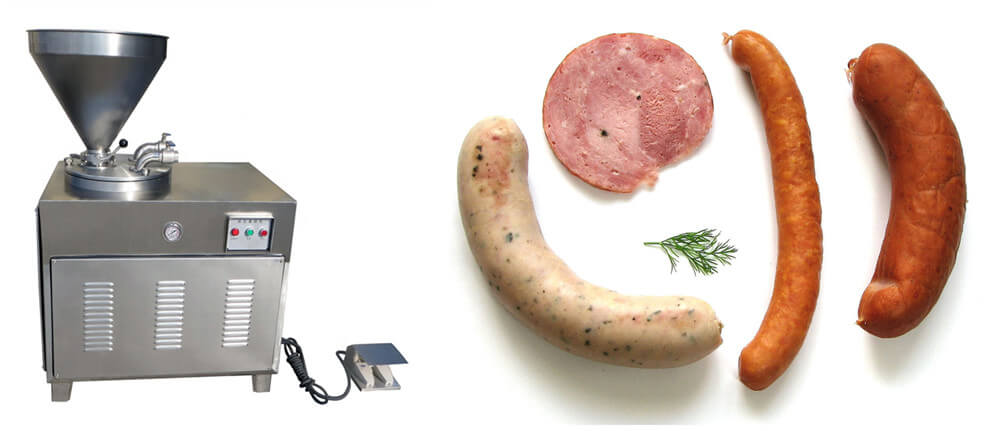

In the evolving landscape of food processing technology, the vacuum sausage filling machine stands out as an indispensable tool for both artisanal and large-scale sausage production. This piece of equipment not only enhances productivity but also ensures that the quality of sausages meets the highest standards expected by consumers today.

Moreover, user-friendliness cannot be overlooked. Training staff to handle these machines proficiently boosts productivity and ensures safety in the workplace. Many models offer intuitive digital controls that manage filling parameters with precision, and some even come with pre-programmed settings for different types of sausages, making the process more straightforward and minimizing human error. In terms of energy consumption, modern vacuum sausage filling machines are more efficient than their predecessors, which contributes to reducing operational costs in the long term. Be sure to look for machines that are energy-star rated or come with eco-friendly features to align with sustainable practices. As health consciousness becomes a priority for many consumers, using a vacuum sausage filling machine supports the production of leaner sausages with less fat content, which satisfies the growing demand for healthier food options. The precision of filling also means that producers can create sausages with specific nutritional profiles by accurately controlling the amount and type of ingredients. Case studies from successful sausage manufacturers have highlighted the transformative impact that investing in a high-quality vacuum sausage filling machine can have on business operations. Reports of increased output, improved product quality, and better compliance with health and safety standards are not uncommon. In conclusion, for any serious player in the sausage manufacturing industry, a vacuum sausage filling machine is not just an option but a necessity. Marrying advanced technology with traditional practices, this equipment exemplifies how innovation can enhance both efficiency and excellence in the production line. As with all significant investments, thorough research and diligent consideration of specific business needs will ensure that the chosen machine offers the best return on investment.

Moreover, user-friendliness cannot be overlooked. Training staff to handle these machines proficiently boosts productivity and ensures safety in the workplace. Many models offer intuitive digital controls that manage filling parameters with precision, and some even come with pre-programmed settings for different types of sausages, making the process more straightforward and minimizing human error. In terms of energy consumption, modern vacuum sausage filling machines are more efficient than their predecessors, which contributes to reducing operational costs in the long term. Be sure to look for machines that are energy-star rated or come with eco-friendly features to align with sustainable practices. As health consciousness becomes a priority for many consumers, using a vacuum sausage filling machine supports the production of leaner sausages with less fat content, which satisfies the growing demand for healthier food options. The precision of filling also means that producers can create sausages with specific nutritional profiles by accurately controlling the amount and type of ingredients. Case studies from successful sausage manufacturers have highlighted the transformative impact that investing in a high-quality vacuum sausage filling machine can have on business operations. Reports of increased output, improved product quality, and better compliance with health and safety standards are not uncommon. In conclusion, for any serious player in the sausage manufacturing industry, a vacuum sausage filling machine is not just an option but a necessity. Marrying advanced technology with traditional practices, this equipment exemplifies how innovation can enhance both efficiency and excellence in the production line. As with all significant investments, thorough research and diligent consideration of specific business needs will ensure that the chosen machine offers the best return on investment.

Next:

Latest news

-

High Speed Filler-Linker-Hanger Line for Efficient Production

NewsAug.18,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Sausage Production Line, Small Meat Shop Equipment

NewsAug.17,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Efficiency & Precision

NewsAug.17,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery|Sausage Production Line,Pneumatic Technology

NewsAug.17,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Sausage Production, Automated Clipping

NewsAug.17,2025

-

High-Speed Filler-Linker-Hanger Line: Boost Production

NewsAug.17,2025