Feb . 12, 2025 18:48 Back to list

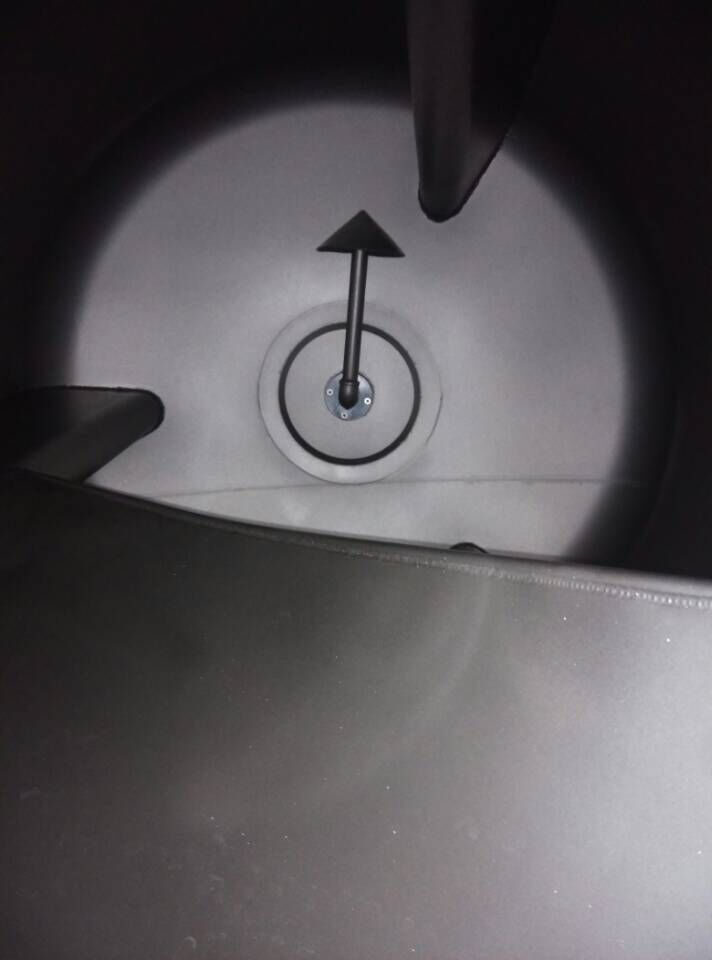

meat bin lifter

When it comes to optimizing productivity and safety in industrial settings, the meat bin lifter is a quintessential tool that deserves attention. For those operating in the meat processing industry, this equipment not only enhances operational efficiency but also contributes significantly to workplace safety. Utilizing state-of-the-art engineering and ergonomic design, these lifters effectively minimize the physical strain on workers, simultaneously reducing the risk of injuries associated with manual lifting tasks.

Trustworthiness of the meat bin lifter is evidenced by the numerous testimonials and case studies from businesses that have witnessed tangible improvements post-implementation. Companies report substantial reductions in workplace injuries and associated downtime, showcasing these lifters as a reliable solution for operational challenges in meat processing. The trust extends to the manufacturers who offer robust customer support, ensuring that the lifters are properly maintained and any technical issues are swiftly addressed. The benefits of investing in a meat bin lifter are multifold. Not only do they present a practical solution in handling heavy lifting tasks, but they also align with the ethical and legal responsibilities of employers to provide a safe working environment. Additionally, they contribute to a more sustainable operation by optimizing energy usage and manpower efficiency. In conclusion, the adoption of meat bin lifters is not merely a trend but a strategic move towards improved operational efficiency and employee safety. Their design and functionality offer unparalleled benefits, from reducing workplace injuries to ensuring compliance with regulatory standards. For any business within meat processing, integrating a meat bin lifter into their workflow represents a forward-thinking approach, marked by professionalism and a steadfast dedication to quality and safety in the workplace. Therefore, any stakeholder within the industry should consider the meat bin lifter not as an expense but as an investment toward operational excellence and employee welfare.

Trustworthiness of the meat bin lifter is evidenced by the numerous testimonials and case studies from businesses that have witnessed tangible improvements post-implementation. Companies report substantial reductions in workplace injuries and associated downtime, showcasing these lifters as a reliable solution for operational challenges in meat processing. The trust extends to the manufacturers who offer robust customer support, ensuring that the lifters are properly maintained and any technical issues are swiftly addressed. The benefits of investing in a meat bin lifter are multifold. Not only do they present a practical solution in handling heavy lifting tasks, but they also align with the ethical and legal responsibilities of employers to provide a safe working environment. Additionally, they contribute to a more sustainable operation by optimizing energy usage and manpower efficiency. In conclusion, the adoption of meat bin lifters is not merely a trend but a strategic move towards improved operational efficiency and employee safety. Their design and functionality offer unparalleled benefits, from reducing workplace injuries to ensuring compliance with regulatory standards. For any business within meat processing, integrating a meat bin lifter into their workflow represents a forward-thinking approach, marked by professionalism and a steadfast dedication to quality and safety in the workplace. Therefore, any stakeholder within the industry should consider the meat bin lifter not as an expense but as an investment toward operational excellence and employee welfare.

Next:

Latest news

-

Premounted Side Disc for Efficient Operation - AI-Enhanced

NewsAug.04,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Precision, Efficiency, Innovation

NewsAug.03,2025

-

Sausage Link Cutter JC999-03 | Fast & Precise Sausage Slicing Tool

NewsAug.03,2025

-

Pneumatic Clipping Machine- Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Sausage Production Line, High Efficiency

NewsAug.03,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Sausage Production Line, Efficient Meat Processing

NewsAug.03,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Precision Efficiency

NewsAug.03,2025