সেপ্টে. . 28, 2024 07:21 Back to list

Comprehensive Guide to Food Processing Equipment Pricing and Options

Understanding Food Processing Equipment Price Lists

In the ever-evolving world of food manufacturing, food processing equipment plays a critical role in ensuring efficiency, quality, and safety. For businesses in the food industry, navigating the complexities of purchasing this equipment can be challenging, especially when it comes to understanding price lists. This article aims to provide insight into food processing equipment price lists and the factors that influence these prices.

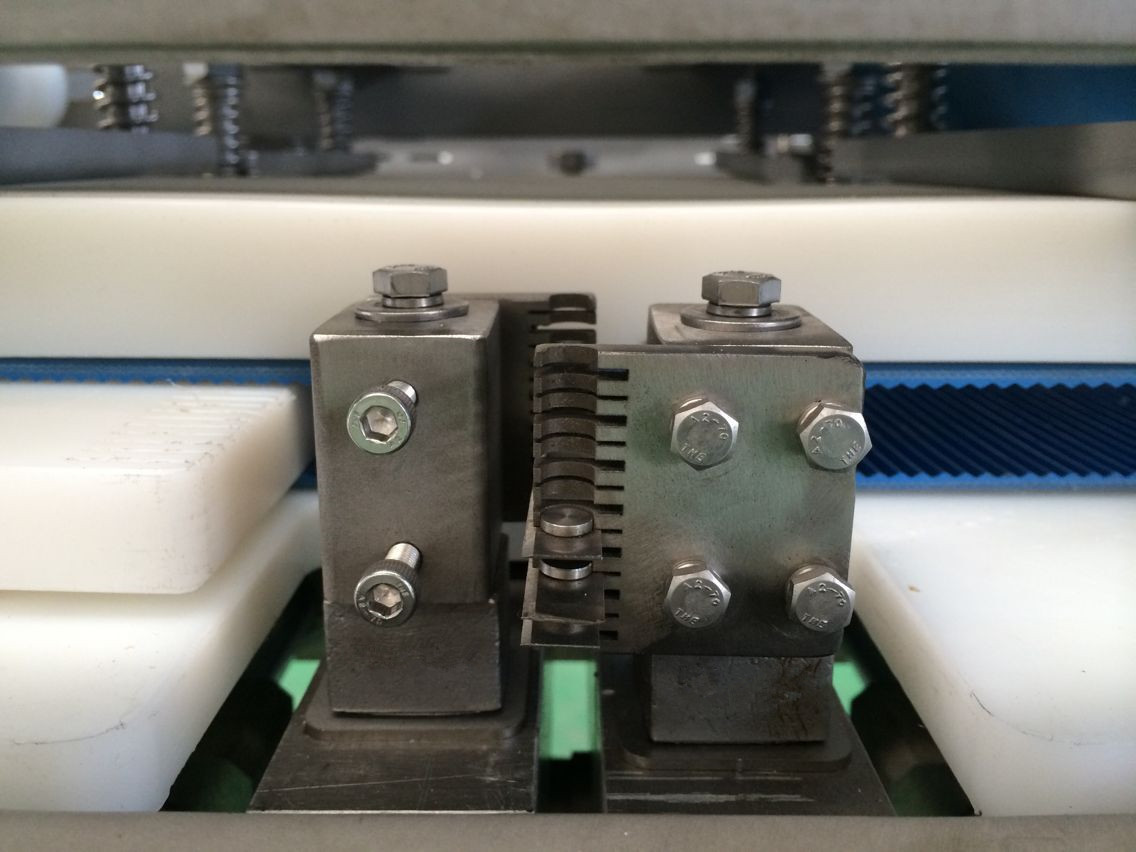

Food processing equipment encompasses a wide range of machines and tools designed to process, package, and preserve food. Common types of equipment include mixers, blenders, slicers, grinders, and packaging machines. The price for these items can vary significantly based on several factors.

1. Type and Functionality of Equipment The primary determinant of price is the type of equipment and its intended functionality. For instance, a basic commercial food blender may cost less than a high-capacity automated mixing system designed for large-scale operations. Specialized equipment, such as vacuum sealers or pasteurizers, typically comes with a higher price tag due to their advanced technology and specific applications.

2. Brand and Manufacturer Brand reputation also plays a crucial role in pricing. Renowned brands that offer durable and reliable equipment may charge a premium compared to lesser-known manufacturers. Businesses often opt for well-established brands because they provide better after-sales service, warranties, and support, which can lead to long-term savings.

food processing equipment pricelist

3. Equipment Size and Capacity Another significant factor is the size and capacity of the equipment. Larger machines designed to handle higher volumes of food will usually cost more than their smaller counterparts. For example, industrial ovens that can cook thousands of meals at once tend to be more expensive than smaller, countertop models suitable for small establishments.

4. Technology and Features Modern food processing equipment often comes equipped with advanced technology, such as automation, programmable settings, and energy-efficient designs. These high-tech features enhance productivity and reduce operational costs over time, but they can also raise the initial purchase price. Businesses must weigh the upfront investment against potential long-term savings when choosing equipment.

5. Market Demand and Supply Finally, market dynamics also influence prices. Fluctuations in demand, availability of raw materials, and technological advancements can lead to changes in equipment pricing. During peak seasons, prices may rise due to increased demand, while off-peak times may offer opportunities for discounts and promotions.

When reviewing a food processing equipment price list, it's essential for businesses to conduct thorough research. Comparing different models, understanding the specifications, and considering future operational needs will help ensure that the investment made is beneficial in the long run. Moreover, consulting with industry experts or suppliers can provide additional insights into cost-effective options and emerging technologies in food processing.

In conclusion, a food processing equipment price list is not merely a numerical representation of costs; it reflects a variety of influencing factors that businesses must consider to make informed purchasing decisions. Understanding these factors helps companies optimize their production capabilities while ensuring quality and compliance in their food processes.