nov. . 22, 2024 04:08 Back to list

pneumatic sausage clipper factory

Understanding the Pneumatic Sausage Clipper Factory

In the world of food processing, efficiency and precision are key factors that dictate the quality of the final product. A significant aspect of this process is packaging, where pneumatic sausage clippers play a crucial role. A pneumatic sausage clipper factory specializes in the production of these advanced packaging machines, which streamline operations in the food industry by ensuring that sausages are securely sealed and packaged for consumer distribution.

Pneumatic sausage clippers utilize compressed air systems to firmly fasten clips around sausage casings, ensuring that the product is airtight and can withstand transportation. The technology behind these machines allows for rapid operation, which is essential in high-volume production settings. Unlike manual clipping methods, pneumatic systems reduce labor intensity and increase the consistency of the sealing process, ultimately enhancing product quality.

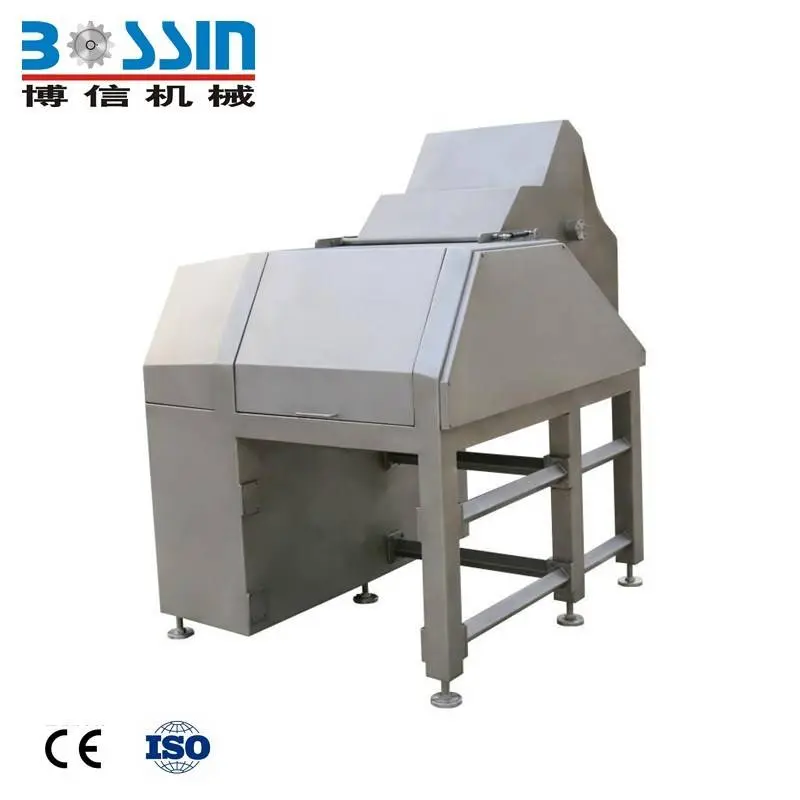

The factory itself is a hub of innovation and engineering excellence, employing skilled workers, designers, and technicians who collaborate to create high-performance equipment. The production process begins with the design phase, where engineers utilize computer-aided design (CAD) software to create precise models of the clipper machines. Following design validation, raw materials such as stainless steel, which is resistant to corrosion and easy to clean, are procured.

pneumatic sausage clipper factory

Once the materials are sourced, the manufacturing process involves several stages, including machining, assembly, and quality control. CNC machines are often employed to cut and shape components with high precision, ensuring that each part fits perfectly into the final assembly. After assembly, rigorous testing is conducted to evaluate the machine's performance under real-world conditions. This quality assurance step is crucial, as it guarantees that every clipper meets the factory’s high standards and industry regulations.

In addition to manufacturing clippers, a reputable factory also offers maintenance and support services. Given the fast-paced nature of food processing, any downtime due to equipment failure can be costly. Thus, effective after-sales service, including routine maintenance and prompt repairs, is essential to ensure seamless operations for clients.

Sustainability is another aspect increasingly addressed by pneumatic sausage clipper factories. Many are adopting eco-friendly practices in their production processes, utilizing recyclable materials and energy-efficient machinery to reduce their environmental footprint. This commitment not only meets regulatory standards but also appeals to a growing segment of environmentally conscious consumers.

In conclusion, a pneumatic sausage clipper factory represents a critical component of the modern food processing industry. By harnessing advanced technology and skilled human resources, these factories deliver efficient packaging solutions that underpin the quality and safety of processed meats. As the industry continues to evolve, the role of such factories will remain vital, adapting to new demands and innovations in food production.