Pro . 02, 2024 04:23 Back to list

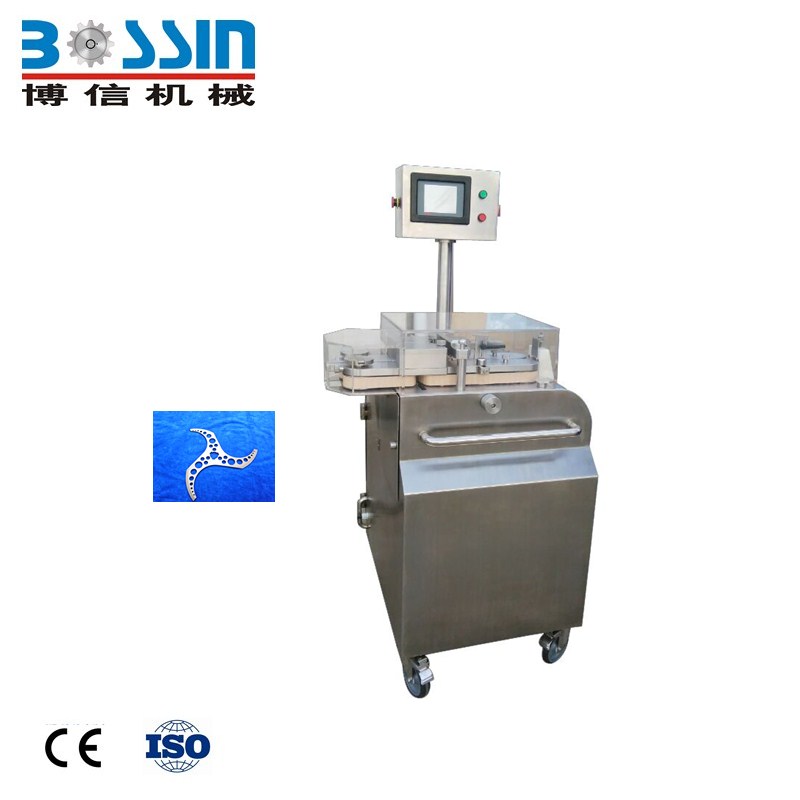

china sausage tie machine

The Evolution and Innovation of the China Sausage Tie Machine

In recent years, the food processing industry has experienced significant advancements, particularly in machinery designed to enhance production efficiency and product quality. One remarkable innovation in this field is the sausage tie machine, especially those developed in China. This sophisticated machine plays a vital role in the sausage manufacturing process, automating the tying of sausages and ensuring a consistent and reliable product.

Understanding the Sausage Tie Machine

The sausage tie machine, as the name suggests, is designed specifically for the purpose of tying sausages after they have been filled with meat or other ingredients. Traditionally, this process was labor-intensive, requiring skilled workers to manually tie each sausage, which could lead to variations in size, shape, and quality. The introduction of the sausage tie machine has revolutionized this aspect of sausage production.

Chinese manufacturers have leveraged advanced engineering techniques and cutting-edge technology to create machines that not only improve efficiency but also maintain high standards of hygiene and precision. Modern sausage tie machines in China are equipped with features that allow for the automated tying of sausages at high speeds, significantly reducing production time and labor costs. Furthermore, these machines can adjust to different sausage sizes and types, making them versatile for various products.

The Mechanism Behind the Machine

The operation of a sausage tie machine is a marvel of engineering. Typically, the process begins with the machine filling the casing with the sausage mixture. This is followed by precise measurement and cutting of the sausage lengths. Once the sausage is in place, the machine employs a tying mechanism that quickly wraps and secures the ends of the sausages, creating a tight seal.

Many modern machines use a combination of pneumatic and mechanical systems that ensure a consistent tying mechanism. The use of programmable logic controllers (PLCs) allows manufacturers to set specific parameters for different products, ensuring high accuracy and minimal waste. As a result, day-to-day production becomes not only faster but also more reliable.

The Benefits of Using a Sausage Tie Machine

china sausage tie machine

The benefits of implementing a sausage tie machine in a production line are manifold. Firstly, efficiency is greatly enhanced; a machine can tie hundreds or even thousands of sausages in a fraction of the time it would take a team of workers. This speed leads to increased output and contributes to a company’s bottom line.

Secondly, the consistency provided by the machine is paramount. Each sausage can be tied to the same specifications, ensuring uniformity in size and presentation. This is particularly important for brands seeking to maintain their reputation for quality. Moreover, automation minimizes human error, resulting in fewer defects and ensuring higher quality control standards.

Hygiene is also drastically improved. Automated systems reduce the amount of human contact with the product, thereby lowering the risk of contamination. In an industry where health and safety standards are critically important, this is a significant advantage.

Trends and Future Developments

As the global food market evolves, so too will the design and functionality of sausage tie machines. The demand for automation is expected to grow, driven by the need for cost-efficiency and productivity in food processing. Innovations such as smart technology and machine learning could play a role in the future of these machines, allowing for real-time monitoring and adjustments based on production metrics.

Additionally, with the increasing focus on sustainability, manufacturers may explore biodegradable casing materials, and tie machines will need to adapt accordingly. The emphasis on environmental impact will encourage the development of energy-efficient machines that require less power while maximizing output.

Conclusion

The sausage tie machine represents a significant leap forward in the food processing industry, particularly within the context of sausage production. As Chinese manufacturers continue to innovate and improve these machines, they are setting new standards for efficiency, quality, and hygiene. The impact of these advancements is evident not only in the production process but also in the quality of products reaching consumers, heralding a new era in meat processing. As we look to the future, the continued integration of technology in the food industry will no doubt lead to even more remarkable innovations that enhance productivity and sustainability.

Latest news

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Automated Clipping&Pneumatic Sausage Filling

NewsAug.09,2025

-

Pneumatic Clipping Machine-SHJZ Bossin Machinery|Precision Efficiency&Automated Clipping

NewsAug.09,2025

-

High-Speed Sausage Filler-Linker-Hanger Line | Automated Efficiency

NewsAug.09,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Efficiency

NewsAug.09,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Automated Meat Processing

NewsAug.08,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd. | Sausage Production Line, Precision Clipping

NewsAug.08,2025