Medi . 23, 2024 05:12 Back to list

battering & breading machine factories

The Evolution of Battering and Breading Machines in Food Manufacturing

In the world of food manufacturing, the demand for efficiency and consistency has never been higher. One of the key technologies that has emerged to meet this demand is the battering and breading machine. These machines play a pivotal role in the production of a variety of food products, especially in the meat and poultry industries, where they ensure that items are evenly coated for optimal flavor and texture.

Battering and breading machines are specially designed to automate the process of applying batter and breading to food products. Traditionally, this task was performed manually, a process that was not only time-consuming but also prone to inconsistency. As the food industry expanded and consumer expectations evolved, the need for reliable, high-capacity machinery became apparent. Thus, the development of specialized machines was initiated.

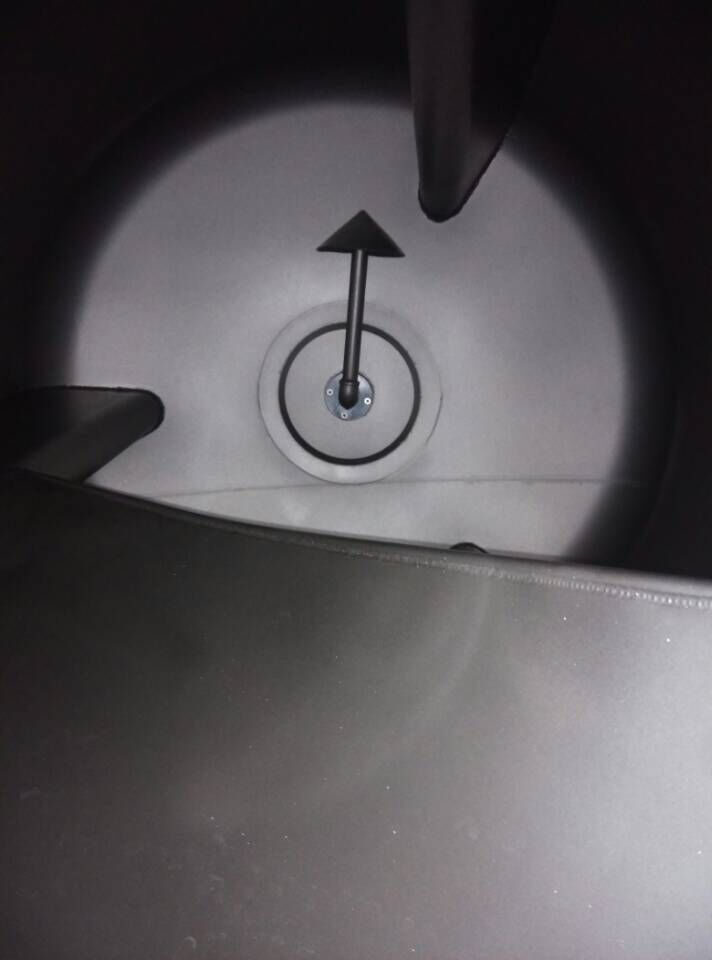

These machines come in various forms, each tailored to specific production needs. The basic functioning of a battering and breading machine involves three primary stages batter application, breading application, and shaking off the excess material. In the batter application stage, the food items are coated with a liquid batter, which enhances flavor and helps the breading adhere. This is often achieved through a series of rollers or dipping mechanisms that ensure complete coverage.

Once the batter is applied, the next stage involves the breading application. Here, the machine sprinkles the breading onto the battered items. This can include various types of breading materials, such as breadcrumbs, flour, or seasoned mixtures, depending on the desired final product. Modern machines utilize a vibration or pneumatic system to ensure an even distribution, maximizing coverage while minimizing waste.

battering & breading machine factories

One of the significant technological advancements in these machines is the ability to adjust settings for different products. Many battering and breading machines now come with programmable controls, allowing manufacturers to customize the thickness of the batter, the type of breading, and the speed of the process. This versatility means that a single machine can handle multiple products, making it a valuable investment for food factories looking to diversify their offerings.

Furthermore, food safety and hygiene have become major concerns in the food processing industry. Advanced battering and breading machines are designed with sanitation in mind, featuring easy-to-clean components and materials that comply with food safety regulations. Manufacturers are increasingly focused on creating machines that not only improve productivity but also uphold high health standards, ensuring that contaminants do not compromise the quality of the food.

The market for battering and breading machines continues to grow, driven by increasing consumer preferences for convenience foods and ready-to-cook products. As technology continues to advance, we can expect to see even more innovative solutions in this space. Factors like automation, enhanced food safety measures, and improved energy efficiency are likely to influence the design and functionality of these machines in the future.

In conclusion, battering and breading machines have transformed the food manufacturing landscape, offering enhanced efficiency, consistency, and hygiene standards. As factories continue to adapt to changing consumer needs and market demands, these machines will undoubtedly play a crucial role in shaping the future of food production. The ongoing evolution of this technology promises to bring even greater improvements, ensuring that manufacturers can keep pace with the ever-increasing appetite for quality food products.