dec . 20, 2024 10:50 Back to list

Top Manufacturers of Sausage Dosing Fillers for Optimal Production Efficiency

The Evolution of Sausage Dosing Filler Manufacturers An Insight into Modern Practices

In the world of meat processing, sausage production stands out as an art that blends tradition with modern innovation. One of the critical elements in this process is the use of dosing fillers, which play a vital role in ensuring the efficiency, quality, and consistency of sausage manufacturing. This article explores the evolution of sausage dosing filler manufacturers, their contributions to the industry, and the latest trends shaping their practices.

Understanding Sausage Dosing Fillers

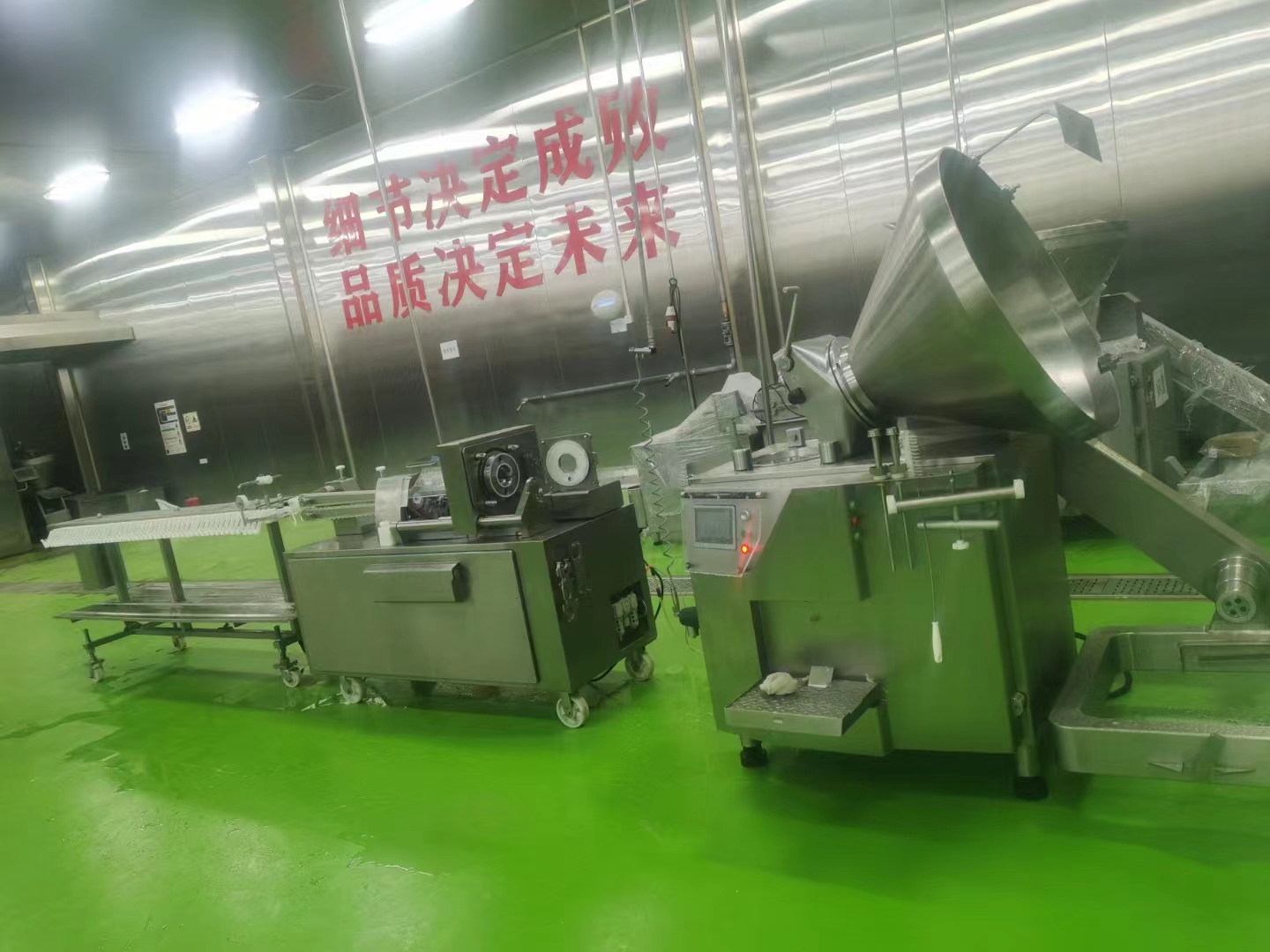

Sausage dosing fillers, often referred to simply as fillers, are machines designed to accurately dispense meat mixtures into casings. The quality of these fillers directly affects the final product, influencing factors such as texture, flavor distribution, and overall freshness. Traditionally, sausage fillers relied on manual operations, where workers would pack the meat into casings using rudimentary methods. However, advancements in technology have revolutionized this aspect of production.

Today's fillers are equipped with sophisticated hydraulic or pneumatic systems that ensure precise dosing and minimal waste. These machines can handle various sausage recipes, from fine-ground emulsified products to chunky varieties, accommodating different sizes and styles of casings. As consumer preferences evolve, the demand for versatility in production processes has prompted manufacturers to innovate continually.

Leading Manufacturers and Their Innovations

Several key players dominate the market for sausage dosing fillers. Companies like Marel, Handtmann, and Sauer have made significant strides in developing advanced machinery that not only enhances productivity but also ensures the integrity of the meat. These manufacturers invest heavily in research and development to produce fillers that are efficient, easy to clean, and environmentally friendly.

For instance, Marel has introduced fillers that incorporate cutting-edge digital technologies, enabling real-time monitoring of production processes. This feature allows manufacturers to adjust parameters on the fly, ensuring optimal consistency and reducing the chances of overfilling or underfilling casings. Handtmann's offerings include machines capable of processing diverse ingredients, catering to the increasing consumer demand for gourmet and artisan sausages.

sausage dosing filler manufacturers

Sustainability and Eco-Friendly Practices

With growing awareness of environmental issues, sausage dosing filler manufacturers are also focusing on sustainability. The meat industry has a significant carbon footprint, so manufacturers are making strides to reduce waste and energy consumption. Innovations such as energy-efficient motors and smart controls are becoming standard in new machinery, helping to lower emissions and operational costs.

Moreover, some manufacturers are exploring biodegradable casings and incorporating sustainable sourcing practices into their production processes. By prioritizing eco-friendly solutions, dosing filler manufacturers are aligning themselves with modern consumer values, which increasingly favor sustainability without compromising quality.

Future Trends in Sausage Dosing Fillers

As we look to the future, several trends are likely to shape the landscape of sausage dosing filler manufacturers. Automation is at the forefront, with a push towards fully automated production lines that minimize human error and enhance productivity. The integration of artificial intelligence and machine learning will further optimize processes, allowing for predictive maintenance and downtime reduction.

Additionally, the growing trend of plant-based and alternative proteins means that dosing fillers must adapt to handle these new materials. Manufacturers are already experimenting with fillers that can accommodate not just traditional meat products but also a wide array of plant-based mixtures.

Conclusion

Sausage dosing filler manufacturers play a crucial role in the meat processing industry, contributing to efficiency, quality, and sustainability. As technology continues to advance, these manufacturers are not only improving production processes but also embracing eco-friendly practices that align with consumer expectations. The future of sausage production looks promising, with innovations and adaptations ensuring that this beloved food remains a staple in diets worldwide, all while minimizing its impact on the planet. The evolution of dosing fillers is a testament to the industry's commitment to excellence, sustainability, and meeting the changing demands of consumers.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025