Νοέ . 13, 2024 06:04 Back to list

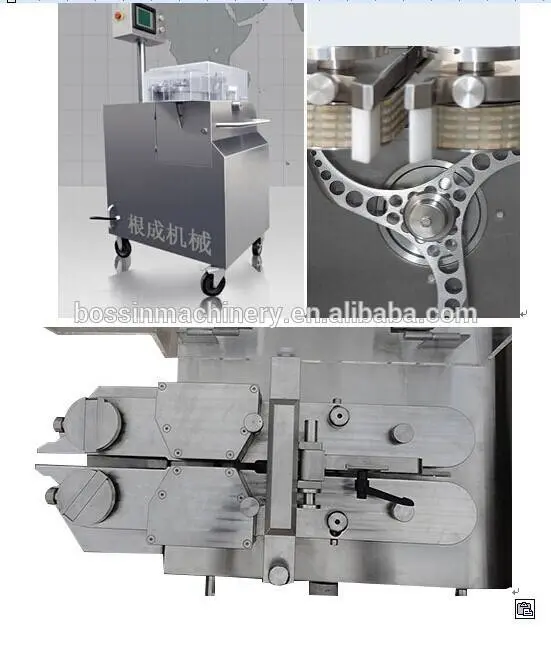

rotor for vacuum filler

Understanding the Rotor for Vacuum Fillers A Key Component in Food Processing

In the world of food processing, efficiency and hygiene are paramount. One critical component that plays a significant role in this sector is the rotor for vacuum fillers. These devices are widely used in the food industry for accurately portioning and filling products into packaging, ensuring that both quality and consistency are maintained.

The rotor in a vacuum filler functions as the heart of the machine. It is designed to create a vacuum that pulls the product into the filling chamber, allowing for precise volume control. This means that manufacturers can fill containers, sausages, and other products with the exact amount needed, minimizing waste and ensuring that each unit is identical. The accuracy of the filling process is essential for maintaining customer satisfaction and adhering to regulatory standards.

One of the primary advantages of using a rotor in vacuum fillers is the reduction of air in the filling process. The vacuum environment helps in preserving the freshness and quality of the product by minimizing oxidation. This is particularly important for meat products, where exposure to air can lead to spoilage and a decrease in shelf life. The rotor’s capability to maintain a low-pressure environment extends not just to the filling phase, but also helps in ensuring that delicate ingredients retain their integrity.

rotor for vacuum filler

Moreover, hygiene is a critical factor in food processing, and the design of rotors for vacuum fillers often prioritizes easy cleaning and maintenance. Many manufacturers produce rotors that can be disassembled with ease, allowing for thorough cleaning after production runs. This practice not only helps in maintaining the quality of the product but also in preventing cross-contamination between batches.

Another aspect to consider is the material used in manufacturing rotor components. High-quality stainless steel is often chosen for its durability and resistance to corrosion, ensuring that the equipment lasts longer and operates efficiently in demanding environments. Innovations in these materials and designs continue to enhance the reliability of vacuum fillers, thus supporting the ever-growing needs of the food industry.

In conclusion, the rotor for vacuum fillers is an indispensable component in modern food processing. Its ability to provide precision, maintain product quality, and promote hygiene makes it a vital asset for manufacturers looking to optimize their production lines. As technology advances, we can anticipate further improvements in rotor design, leading to even more efficient and reliable filling processes, which will ultimately benefit consumers and producers alike. Understanding the importance of this component is crucial for anyone involved in the food processing industry as they strive to meet the increasing demands for quality and efficiency.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025