Dic . 03, 2024 16:35 Back to list

semi-automatic sausage tying machine quotes

The Rise of Semi-Automatic Sausage Tying Machines A Modern Solution for the Food Industry

In the ever-evolving landscape of the food industry, efficiency and productivity are paramount. Among the myriad of innovations that have surfaced, the semi-automatic sausage tying machine has carved out a significant niche. This technology not only streamlines the sausage production process but also enhances consistency and quality, addressing the growing demands of both small artisans and large-scale manufacturers. In this article, we will explore the features, benefits, and implications of adopting semi-automatic sausage tying machines in today's food production environments.

Understanding Semi-Automatic Sausage Tying Machines

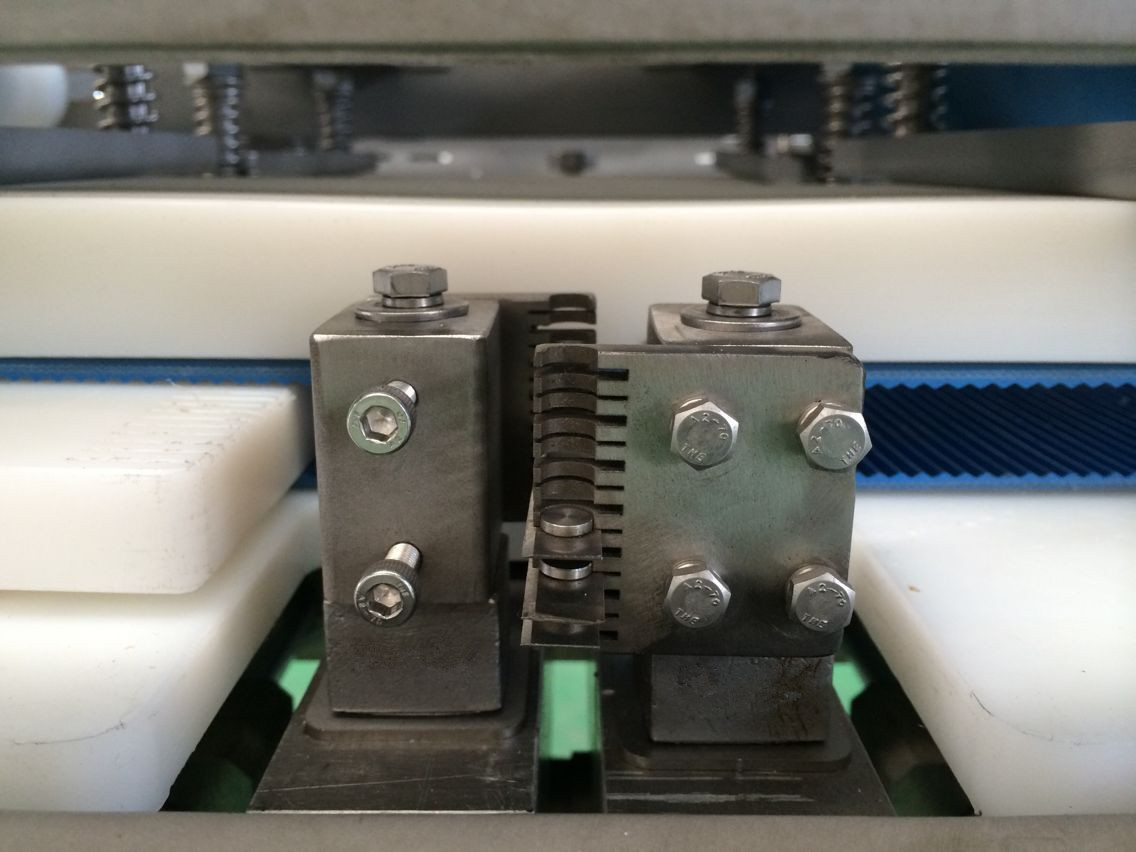

Semi-automatic sausage tying machines are designed to assist in the tying process of sausage casings, offering a blend of manual intervention and automated technology. Unlike fully automatic machines that require little to no human involvement, semi-automatic machines allow operators to maintain a level of control while significantly reducing the amount of labor required for repetitive tasks.

These machines typically consist of a feeding mechanism, a tying mechanism, and control panels that manage the operation. Operators can load the sausage casings and initiate the tying process with the push of a button, allowing them to focus on other essential tasks, such as quality control or product formulation.

Advantages of Using Semi-Automatic Sausage Tying Machines

1. Improved Efficiency The primary benefit of semi-automatic machines is their ability to increase production speed. Traditional methods of tying sausages can be time-consuming and labor-intensive. By integrating automation, these machines can help producers tie sausages more quickly, thereby significantly increasing output.

2. Cost-Effectiveness Investing in semi-automatic equipment can lead to substantial cost savings over time. While the initial purchase may require a notable investment, the long-term reduction in labor costs and increased production rates often justify the expense. Additionally, they can reduce waste by ensuring a consistent tying force, which helps maintain the integrity of the sausage.

3. Enhanced Product Consistency Manual tying processes can result in variations in the tightness and appearance of sausages. Semi-automatic machines provide precise control over tying parameters, ensuring that every sausage is tied uniformly. This consistency not only improves the visual appeal but also affects the cooking and shelf-life of the product.

4. Flexibility These machines can often be adjusted to accommodate different sizes and types of sausages, making them suitable for a wide range of products. Whether it’s a thin bratwurst or a thicker Italian sausage, operators can easily modify the settings to meet their production needs.

semi-automatic sausage tying machine quotes

5. Reduction of Physical Strain The manual labor involved in sausage production can lead to repetitive strain injuries. By automating the tying process, semi-automatic machines lessen the physical burden on workers, contributing to a safer workplace and reducing downtime due to injury.

Considerations When Choosing a Semi-Automatic Sausage Tying Machine

When looking to invest in a semi-automatic sausage tying machine, several factors should be taken into account

- Production Volume Understanding your production requirements is crucial. The machine selected should be capable of handling your expected output without compromising quality.

- Maintenance and Support As with any machinery, regular maintenance is essential. Companies that offer strong customer support and easy access to spare parts will prove invaluable.

- Operational Training Adequate training for staff on how to operate the machines is vital. Investing in training programs can help maximize the machine’s efficiency and ensure proper handling.

- Space Requirements Consider the footprint of the machine and how it will fit into your existing production line. Space planning is critical for maintaining workflow efficiency.

Conclusion

The integration of semi-automatic sausage tying machines represents a forward-thinking approach to modern food production. By enhancing efficiency, reducing costs, and promoting consistency, these machines provide valuable solutions for producers aiming to meet the rising demands of consumers. As the food industry continues to embrace technology, the semi-automatic sausage tying machine stands out as an essential tool, driving both productivity and quality in sausage production. For businesses looking to modernize their operations, this investment not only reflects a commitment to innovation but also a dedication to delivering superior products.

Latest news

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd. | Sausage Production Line, Precision Clipping

NewsAug.08,2025

-

Pneumatic Clipping Machine: Automated Sausage Production Solution | Shijiazhuang Bossin Machinery Equipment Co., Ltd. | Automated Clipping, Hygienic Design

NewsAug.08,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Automated Clipping

NewsAug.08,2025

-

Fast & Efficient Frozen Meat Block Flaker Machine

NewsAug.08,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery|Sausage Production Efficiency&Hygiene

NewsAug.08,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsAug.07,2025