veebr. . 13, 2025 10:06 Back to list

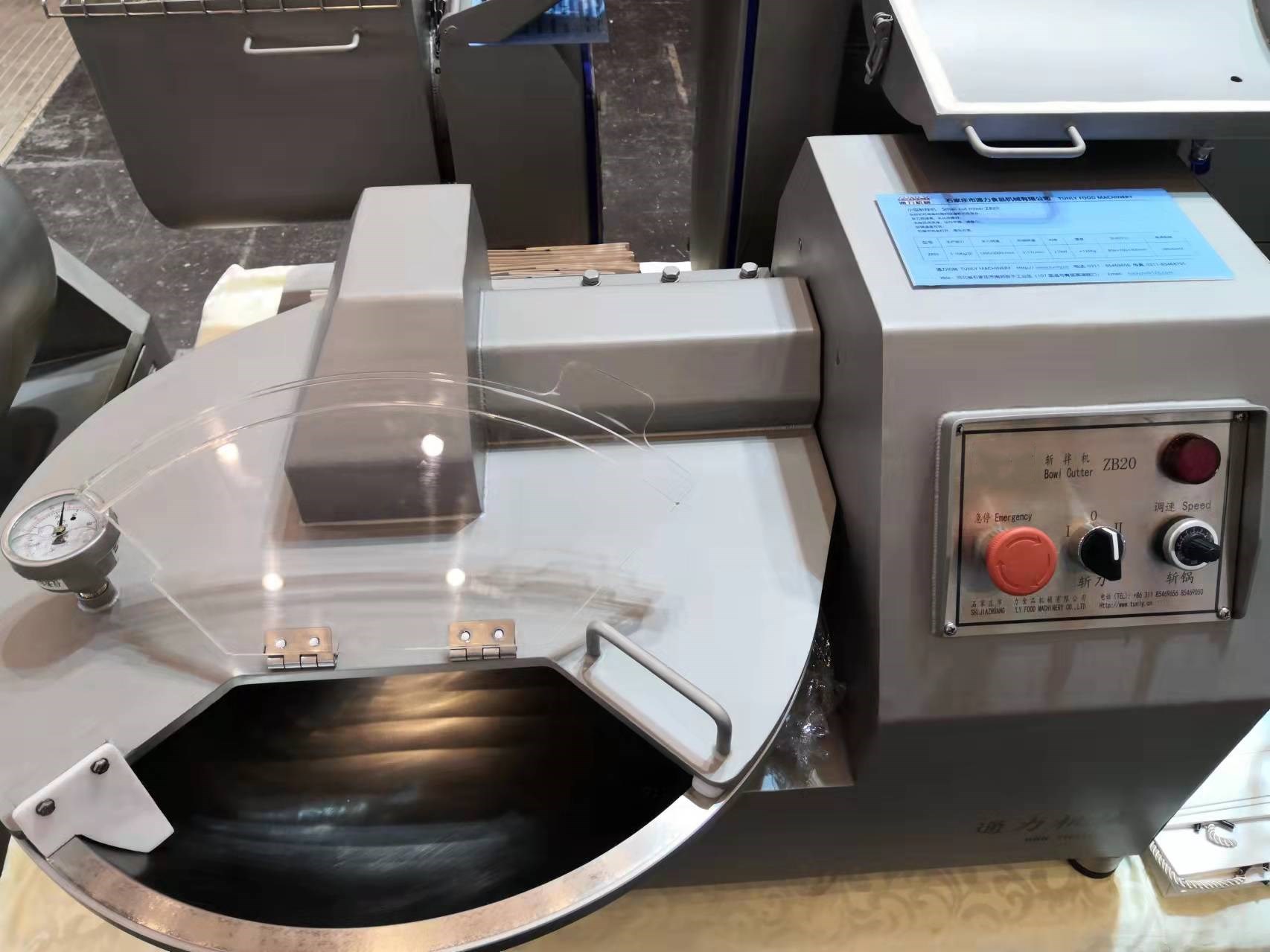

filling mixer

In the dynamic world of food processing and packaging, the filling mixer stands as a pivotal instrument in ensuring product consistency, efficiency, and quality. It is more than just a piece of machinery; it represents the culmination of engineering prowess and industry insights aimed at enhancing production processes across various sectors.

Authoritative sources within the industry affirm that filling mixers are indispensable for businesses looking to scale their production processes without sacrificing quality. For small to medium enterprises (SMEs), adopting such technology can be a game-changer, granting a competitive edge in a crowded marketplace. Commercial giants, too, leverage these machines to ensure consistency across large product batches, enhancing brand reliability and customer satisfaction. Trustworthiness surrounding the use of filling mixers is reinforced through rigorous testing and customer feedback loops. Manufacturers conduct comprehensive trials to confirm that each unit delivers consistent results over its lifespan, standing up to the daily challenges of production environments. Customers are encouraged to participate in demonstrations and pre-purchase trials to affirm the equipment’s performance against their specific needs. This approach not only cements trust but also builds long-term relationships between suppliers and operators. To fully exploit the benefits that come with a filling mixer, businesses need to be discerning about their choices. Factors such as the viscosity of products, production volume, and integration capabilities with existing systems should all influence the selection process. Investing in a machine that aligns with operational demands ensures both profitability and sustainability in the long term. In conclusion, the filling mixer is a testament to advanced engineering that plays an indispensable role in the modern manufacturing and processing landscape. By streamlining operations, maintaining product quality, and adhering to industry standards, these devices substantiate their worth as a strategic investment for any business aiming to thrive in the competitive food processing industry. The continuous advancements in technology promise further enhancements, making filling mixers a cornerstone of food production now and in the future.

Authoritative sources within the industry affirm that filling mixers are indispensable for businesses looking to scale their production processes without sacrificing quality. For small to medium enterprises (SMEs), adopting such technology can be a game-changer, granting a competitive edge in a crowded marketplace. Commercial giants, too, leverage these machines to ensure consistency across large product batches, enhancing brand reliability and customer satisfaction. Trustworthiness surrounding the use of filling mixers is reinforced through rigorous testing and customer feedback loops. Manufacturers conduct comprehensive trials to confirm that each unit delivers consistent results over its lifespan, standing up to the daily challenges of production environments. Customers are encouraged to participate in demonstrations and pre-purchase trials to affirm the equipment’s performance against their specific needs. This approach not only cements trust but also builds long-term relationships between suppliers and operators. To fully exploit the benefits that come with a filling mixer, businesses need to be discerning about their choices. Factors such as the viscosity of products, production volume, and integration capabilities with existing systems should all influence the selection process. Investing in a machine that aligns with operational demands ensures both profitability and sustainability in the long term. In conclusion, the filling mixer is a testament to advanced engineering that plays an indispensable role in the modern manufacturing and processing landscape. By streamlining operations, maintaining product quality, and adhering to industry standards, these devices substantiate their worth as a strategic investment for any business aiming to thrive in the competitive food processing industry. The continuous advancements in technology promise further enhancements, making filling mixers a cornerstone of food production now and in the future.

Next:

Latest news

-

Premounted Side Disc for Efficient Operation - AI-Enhanced

NewsAug.04,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Precision, Efficiency, Innovation

NewsAug.03,2025

-

Sausage Link Cutter JC999-03 | Fast & Precise Sausage Slicing Tool

NewsAug.03,2025

-

Pneumatic Clipping Machine- Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Sausage Production Line, High Efficiency

NewsAug.03,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Sausage Production Line, Efficient Meat Processing

NewsAug.03,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Precision Efficiency

NewsAug.03,2025