Abe . 13, 2024 06:54 Back to list

Burger Production and Shaping Equipment Manufacturer Solutions for Efficient Food Processing

The Rise of Burger-Making Forming Machines A Revolution in Fast Food Production

In the fast-paced world of fast food, efficiency and consistency are paramount. As consumer demand for burgers continues to rise, the need for innovative production methods has led to the development of specialized machinery, particularly burger-making forming machines. These machines are revolutionizing the way restaurants and food manufacturers produce patties, ensuring uniformity and enhancing productivity.

What Are Burger-Making Forming Machines?

Burger-making forming machines are automated devices designed to streamline the process of creating burger patties

. These machines can efficiently form ground meat or plant-based alternatives into perfectly shaped patties of various sizes and thicknesses. They play a crucial role in fast food establishments and large-scale food production facilities, where producing large quantities of burgers quickly is essential.One of the primary advantages of these machines is their ability to maintain consistency in size and shape. In the fast food industry, a uniform burger is not just a matter of aesthetics; it ensures that each burger cooks evenly and meets the customer's expectations. Traditional hand-formed patties often result in variations that can affect cooking time and flavor. With burger-making machines, operators can achieve precise measurements, resulting in a higher-quality product.

Efficiency and Speed

Another significant benefit of burger-making forming machines is their efficiency. These machines can produce hundreds or even thousands of patties per hour, far exceeding the capacity of manual labor. In an industry where time is money, the ability to quickly and reliably generate large quantities of product is a game-changer. This efficiency is especially critical during peak hours, allowing establishments to serve customers rapidly without compromising quality.

Additionally, these machines reduce labor costs. By automating the patty-forming process, businesses can reallocate human resources to other areas of operation, such as customer service or food preparation. This not only enhances overall productivity but also helps in managing labor shortages, a challenge that many fast food operations face.

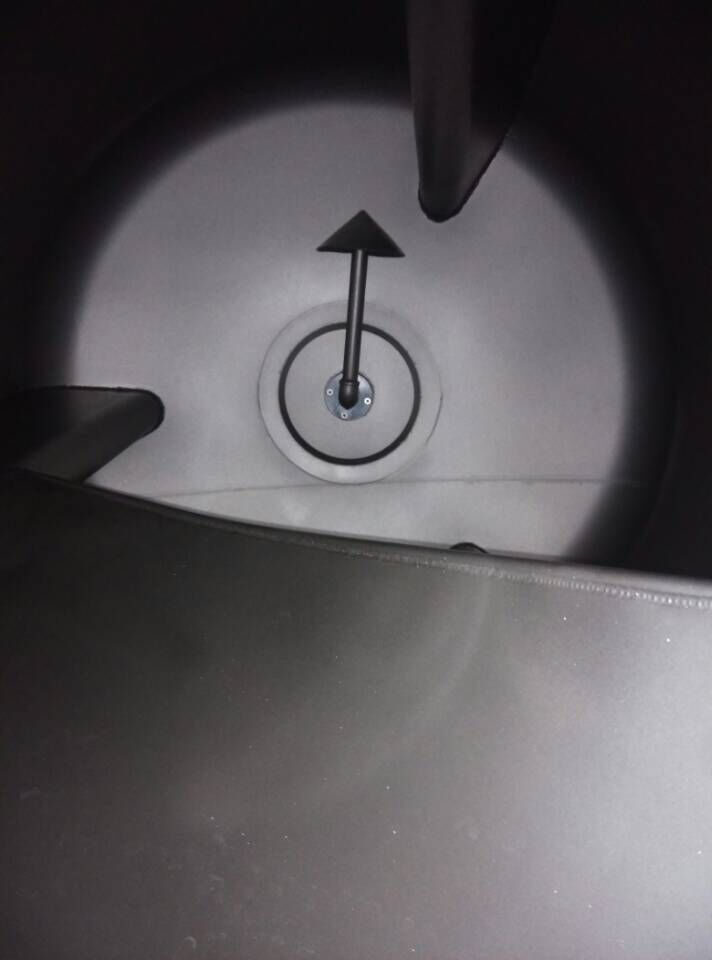

burger making forming machine factory

Customization and Versatility

Modern burger-making forming machines also offer a level of customization that was previously challenging to achieve. Many machines allow operators to adjust the patty's thickness and diameter, accommodating diverse customer preferences. This flexibility is particularly useful as consumer trends shift towards gourmet burgers, healthier options, and plant-based alternatives. For instance, as vegetarian and vegan diets gain popularity, machines can be adapted to handle ingredients like lentils, chickpeas, and beyond.

Moreover, these machines can be integrated into existing production lines, making it easier for businesses to upgrade their operations without overhauling their entire system. This adaptability is vital for restaurants looking to scale their production efficiently while keeping costs manageable.

Quality Control and Food Safety

Another crucial aspect of using burger-making forming machines is the enhancement of food safety and quality control. These machines are designed to minimize human contact with food, reducing the risk of contamination. They are often equipped with features that ensure the meat remains at a safe temperature during production and can be cleaned easily to meet health standards.

Digital technologies have also been incorporated into some machines, allowing for data collection and analysis during production. These advancements enable operators to monitor quality, track inventory, and ensure that the final product meets specific standards.

Conclusion

In summary, burger-making forming machines represent a significant advancement in the food manufacturing industry. By enhancing efficiency, ensuring consistency, and promoting safety, these machines are transforming the way burgers are produced, leading to better quality and faster service. As the demand for burgers continues to grow, investing in modern forming machines will likely become a standard practice for businesses aiming to stay competitive in the fast food landscape. Whether serving classic beef patties or innovative plant-based options, the future of burger production looks promising thanks to these remarkable machines.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025