Abe . 24, 2024 08:50 Back to list

Equipment Manufacturing for Food Production Solutions

The Evolution of Food Production Machine Factories

In recent years, the global demand for food has surged due to population growth, urbanization, and changing dietary habits. This demand has accelerated the development and innovation of food production machine factories, which play a critical role in the food supply chain. These factories are at the forefront of revolutionizing how food is processed, packaged, and distributed, ensuring that the world can meet its nutritional needs efficiently and sustainably.

The Role of Technology in Food Production

Modern food production machine factories are equipped with cutting-edge technology that enhances productivity and precision. Automation and robotics have become increasingly prevalent, allowing processes that were once labor-intensive to be completed in a fraction of the time. For instance, automated sorting and packing machines can handle thousands of units per hour, reducing the workload on human operators and minimizing the risk of errors.

Moreover, advancements in artificial intelligence (AI) and big data analytics have transformed how factories manage their operations. Factory managers can now predict demands, track inventory levels, and optimize production schedules through sophisticated software solutions. This not only increases efficiency but also minimizes waste, helping to address global food shortages and environmental concerns.

Emphasizing Sustainability

As the world grapples with the impacts of climate change and resource depletion, sustainability has become a core focus for food production machine factories. Many manufacturers are now prioritizing eco-friendly practices, from sourcing renewable materials to implementing energy-efficient machinery. For example, factories are investing in energy-efficient motors and smart systems that reduce electricity consumption and lower their carbon footprint.

Additionally, waste reduction is a top priority in modern factories. Techniques such as upcycling food by-products into new products or composting organic waste are being adopted widely. This shift not only contributes to a circular economy but also helps in lowering operating costs and enhancing the corporate image of these factories.

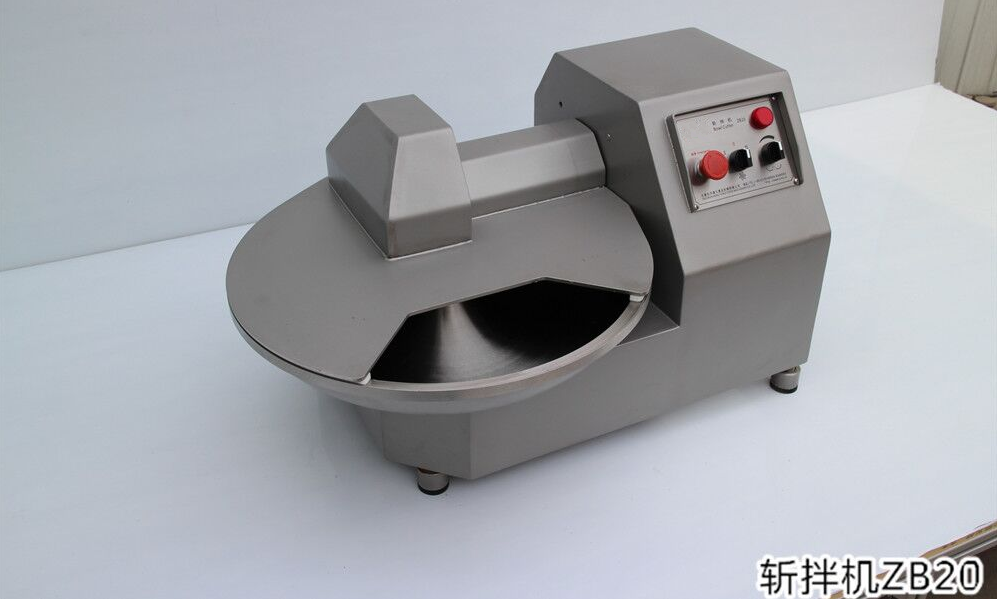

food production machine factory

Innovations in Food Processing Machinery

The machines used in food production are constantly evolving. Innovations such as high-pressure processing (HPP), which uses extreme pressure to preserve food without heat, are gaining traction. This technology extends the shelf life of perishable products while retaining their nutritional value and flavor, a win-win for both manufacturers and consumers.

Furthermore, the integration of Internet of Things (IoT) devices in food production machinery allows for real-time monitoring and maintenance. Sensors provide feedback on machine performance, helping to predict failures before they happen. This proactive maintenance approach significantly reduces downtime and repair costs, ensuring that factories operate at peak efficiency.

Challenges and Future Trends

While the advancements in food production machine factories are remarkable, challenges remain. The workforce must adapt to new technologies, requiring ongoing training and skill development. Additionally, regulatory compliance and food safety standards must be met, adding layers of complexity to factory operations.

Looking ahead, it is clear that the food production machine factory landscape will continue to evolve. The future will likely see even greater integration of AI and machine learning, enabling factories to become smarter and more autonomous. Furthermore, as global awareness about health and sustainability grows, factories will need to innovate continually to meet consumer demands for healthier, ethically produced food.

Conclusion

Food production machine factories are crucial to the modern food ecosystem. Through technological innovation, sustainability efforts, and a commitment to efficiency, these factories are rising to the challenge of feeding a growing population while minimizing their environmental impact. As we look to the future, the ongoing evolution of these facilities will be paramount in achieving a sustainable and resilient food supply chain. The potential for technology to reshape food production is immense, and the journey has only just begun.