Aza . 18, 2024 19:17 Back to list

Efficient Vacuum Mixing Machine for High-Quality Blending in Various Industries

The Benefits of Vacuum Mixing Machines in Modern Manufacturing

In today's fast-paced manufacturing environment, efficiency and quality are paramount. One of the technological advancements that have significantly impacted various industries is the vacuum mixing machine. These machines are essential in applications ranging from food production to pharmaceuticals, offering several advantages that enhance product quality and reduce production costs.

A vacuum mixing machine operates by creating a sealed environment where the mixing process occurs. This environment eliminates air pockets and minimizes the presence of unwanted contaminants, ensuring a uniform mixture of materials. This is particularly crucial in industries where product consistency is vital. For example, in the food sector, vacuum mixing can ensure that ingredients are evenly distributed, which results in a homogeneous product that maintains quality and taste.

One of the primary benefits of vacuum mixing machines is their ability to reduce oxidation. When materials are mixed in an open environment, exposure to air can lead to oxidation, which may affect the color, flavor, and nutritional value of the product. In pharmaceuticals, oxidation can compromise the effectiveness of active ingredients. By using a vacuum mixing machine, manufacturers can significantly minimize these risks, leading to higher-quality end products.

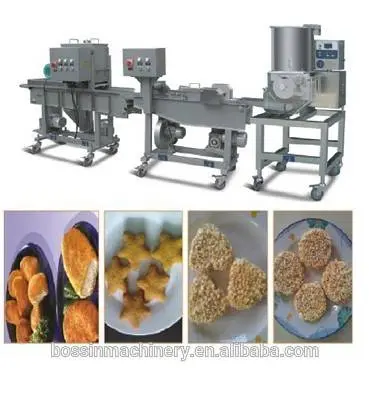

vacuum mixing machine

Additionally, vacuum mixing machines are designed to handle a broad range of materials, including powders, liquids, and even viscous substances. This versatility allows manufacturers to streamline their production processes, as they can use a single machine for various applications. Furthermore, modern vacuum mixers often come equipped with advanced controls and monitoring systems, which enable precise adjustments to mixing parameters, such as pressure and temperature. This level of control is essential for achieving desired product characteristics and complying with stringent industry standards.

Another significant advantage of vacuum mixing machines is the impact they have on production efficiency. The ability to mix materials quickly and uniformly can lead to shorter processing times and reduced overall production cycles. This efficiency not only lowers operational costs but also increases output, allowing manufacturers to respond more effectively to market demands.

Moreover, vacuum mixing technology contributes to sustainability efforts in manufacturing processes. By minimizing waste and optimizing the use of materials, these machines can help organizations reduce their environmental footprint. The ability to precisely control formulations also means that businesses can avoid overuse of expensive ingredients, further promoting sustainability.

In conclusion, vacuum mixing machines represent a significant leap forward in manufacturing technology. Their ability to create a controlled environment that minimizes oxidation, enhances product uniformity, and increases efficiency makes them indispensable in various industries. As manufacturers continue to seek ways to improve quality and reduce costs, the adoption of vacuum mixing technology is likely to grow, paving the way for innovations that further elevate the standards of product quality and production efficiency. Whether in food manufacturing, pharmaceuticals, or other sectors, the impact of vacuum mixing machines is profound, fostering a new era of manufacturing excellence.

Latest news

-

Great Wall DKJC Series Auto Sausage Clipper: Efficient & Durable

NewsJul.25,2025

-

Pneumatic Clipping Machine: Efficient and Reliable Solution for Industrial Applications|Precision Cutting, Durability

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Precision Cutting, High-Speed Operations

NewsJul.21,2025