joulu . 19, 2024 03:52 Back to list

chicken breast fillet machine factories

The Emergence of Chicken Breast Fillet Machine Factories Revolutionizing the Poultry Industry

In recent years, the poultry industry has witnessed significant advancements in technology, particularly with the introduction of specialized machinery designed for processing chicken breast fillets. This innovation has not only streamlined production processes but has also vastly improved product consistency and safety. The rise of chicken breast fillet machine factories is a testament to the industry's drive for efficiency and quality enhancement.

The Need for Automation

Traditionally, the processing of chicken breasts has been a labor-intensive task requiring skilled workers to ensure quality cuts and minimize waste. However, with the increasing demand for chicken products, especially in the health-conscious market, producers are under pressure to maximize output while maintaining high standards. As a result, many farms and processing plants have begun investing in automated machinery that can handle the filleting process efficiently.

Chicken breast fillet machine factories have emerged to meet this growing demand. These facilities specialize in the design and production of machines that can fillet chicken breasts quickly and with minimal human intervention. The best of these machines are capable of processing thousands of birds per hour, making them invaluable to large-scale poultry operations.

Technological Innovations

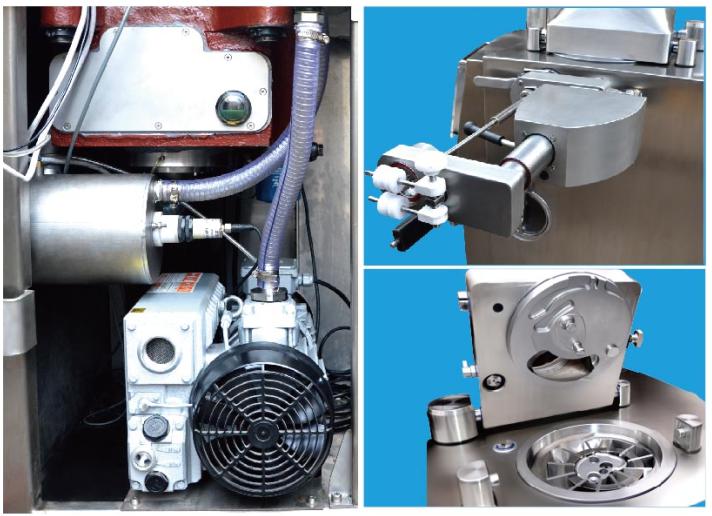

The technology behind chicken breast fillet machines has advanced remarkably. The latest models employ advanced cutting algorithms, ensuring precision in every fillet. These machines are equipped with sensors and cameras that can detect the optimal cutting points on each chicken breast, reducing both waste and the risk of contamination.

Moreover, modern machines are designed for easy cleaning and maintenance, which is crucial in food processing environments. Hygiene is a critical concern in the poultry industry, and manufacturers have responded by incorporating materials and designs that minimize the risk of bacterial growth and cross-contamination. Automated cleaning systems can be integrated into the machines, ensuring that workers spend less time on maintenance and more on production.

Economic Impact

The rise of chicken breast fillet machine factories has significant economic implications. By reducing the reliance on human labor, these machines help offset labor costs, which can fluctuate significantly due to economic factors. Furthermore, automation increases productivity, allowing companies to meet the soaring demand for chicken products in both domestic and international markets.

chicken breast fillet machine factories

Additionally, the investment in such technology can enhance competitiveness. Companies that adopt advanced filleting technology can offer their products at competitive prices without compromising on quality. As a result, those who fail to adapt may find themselves unable to keep up with industry standards or consumer expectations.

Enhancing Product Quality

One of the most notable advantages of chicken breast fillet machines is the enhancement of product quality. With consistent cuts and minimized human error, the end product is not only uniform in size but also superior in appearance. This is particularly important for retailers and consumers who demand high-quality meat products.

Furthermore, automation helps maintain the integrity of the meat. Traditional filleting can sometimes lead to bruising or damage to the meat fibers, affecting taste and texture. Machines designed for this purpose are calibrated to make precise cuts that preserve the quality of the chicken breast, ensuring that customers receive the best possible product.

Future Prospects

As the global demand for poultry products continues to grow, chicken breast fillet machine factories are likely to become increasingly important. Future advancements may include smart technologies, such as the Internet of Things (IoT), where machines can communicate with each other and optimize production processes in real-time. This could lead to even greater efficiencies and waste reduction in poultry processing.

Additionally, as sustainability becomes a more pressing concern for consumers, these factories may incorporate eco-friendly practices, such as energy-efficient machines and waste recycling systems, to minimize their environmental footprint.

Conclusion

Chicken breast fillet machine factories are at the forefront of transforming the poultry industry. By harnessing the power of automation and innovative technology, these factories not only enhance productivity and product quality but also position the industry for sustainable growth. As the demand for chicken products continues to soar, the importance of these specialized factories will only increase, paving the way for a more efficient and quality-driven poultry sector.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025