helmi . 14, 2025 03:27 Back to list

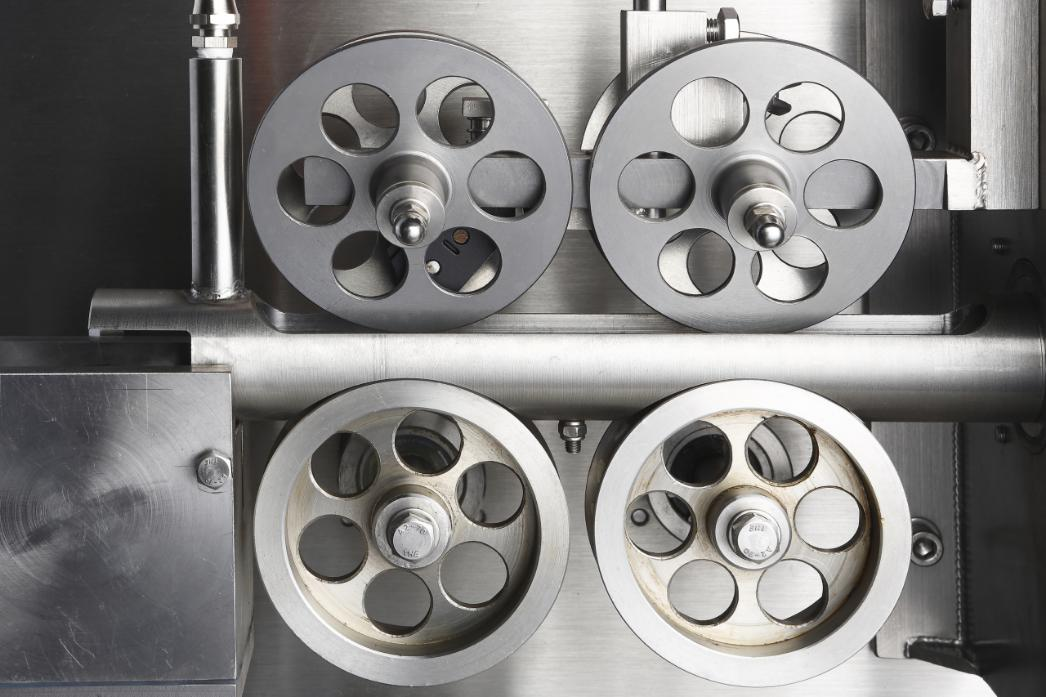

chicken separator machine

Investing in a chicken separator machine can revolutionize the poultry processing industry. As technology evolves, innovations in food processing equipment have become crucial for optimizing efficiency, ensuring high-quality output, and adhering to stringent food safety standards. Based on in-depth research and real-world application, this article delves into the advantages, functionalities, and best practices associated with chicken separator machines, establishing it as an authoritative guide for businesses aiming to maximize their operations.

Making informed purchasing decisions relies heavily on understanding the technical specifications and capabilities of chicken separator machines. It is advisable to consult with manufacturers and industry experts who can provide insights into the most suitable models and configurations tailored to specific operational scales and business objectives. Engaging with knowledgeable professionals increases the authority and trustworthiness of your investment, ensuring that the chosen machinery aligns seamlessly with your processing requirements. The Expert Guidance Certificate that accompanies the purchase of many chicken separator machines exemplifies the manufacturer's commitment to quality and customer satisfaction. This certificate reflects the manufacturer's ongoing dedication to innovation, quality improvement, and client education, all of which build trust and enhance the brand's reputation. Given the competitive landscape of the poultry processing industry, sustainability and energy efficiency are growing priorities. Modern chicken separator machines are engineered to minimize energy consumption, endorsing an eco-friendly operational ethos. By reducing the carbon footprint, businesses not only contribute positively to the environment but also appeal to environmentally conscious consumers, adding a competitive edge in the marketplace. Future advancements in technology promise continued enhancements to these machines, particularly concerning digitization and smart technology integration. Real-time monitoring, predictive maintenance, and data analytics capabilities are set to become standard features, equipping businesses with significant competitive advantages through data-driven operational insights. In conclusion, a chicken separator machine is more than just a piece of equipment; it is an investment in efficiency, safety, and quality production. With expert use, informed decision-making, and an eye towards future technological advancements, businesses can solidify their place as leaders in the poultry processing industry, building an authoritative brand that consumers trust and respect.

Making informed purchasing decisions relies heavily on understanding the technical specifications and capabilities of chicken separator machines. It is advisable to consult with manufacturers and industry experts who can provide insights into the most suitable models and configurations tailored to specific operational scales and business objectives. Engaging with knowledgeable professionals increases the authority and trustworthiness of your investment, ensuring that the chosen machinery aligns seamlessly with your processing requirements. The Expert Guidance Certificate that accompanies the purchase of many chicken separator machines exemplifies the manufacturer's commitment to quality and customer satisfaction. This certificate reflects the manufacturer's ongoing dedication to innovation, quality improvement, and client education, all of which build trust and enhance the brand's reputation. Given the competitive landscape of the poultry processing industry, sustainability and energy efficiency are growing priorities. Modern chicken separator machines are engineered to minimize energy consumption, endorsing an eco-friendly operational ethos. By reducing the carbon footprint, businesses not only contribute positively to the environment but also appeal to environmentally conscious consumers, adding a competitive edge in the marketplace. Future advancements in technology promise continued enhancements to these machines, particularly concerning digitization and smart technology integration. Real-time monitoring, predictive maintenance, and data analytics capabilities are set to become standard features, equipping businesses with significant competitive advantages through data-driven operational insights. In conclusion, a chicken separator machine is more than just a piece of equipment; it is an investment in efficiency, safety, and quality production. With expert use, informed decision-making, and an eye towards future technological advancements, businesses can solidify their place as leaders in the poultry processing industry, building an authoritative brand that consumers trust and respect.

Next:

Latest news

-

Premounted Side Disc for Efficient Operation - AI-Enhanced

NewsAug.04,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Precision, Efficiency, Innovation

NewsAug.03,2025

-

Sausage Link Cutter JC999-03 | Fast & Precise Sausage Slicing Tool

NewsAug.03,2025

-

Pneumatic Clipping Machine- Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Sausage Production Line, High Efficiency

NewsAug.03,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Sausage Production Line, Efficient Meat Processing

NewsAug.03,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Precision Efficiency

NewsAug.03,2025