Déc . 16, 2024 18:51 Back to list

vacuum stuffing machine factory

Vacuum Stuffing Machine Factory Innovation and Quality in Food Production

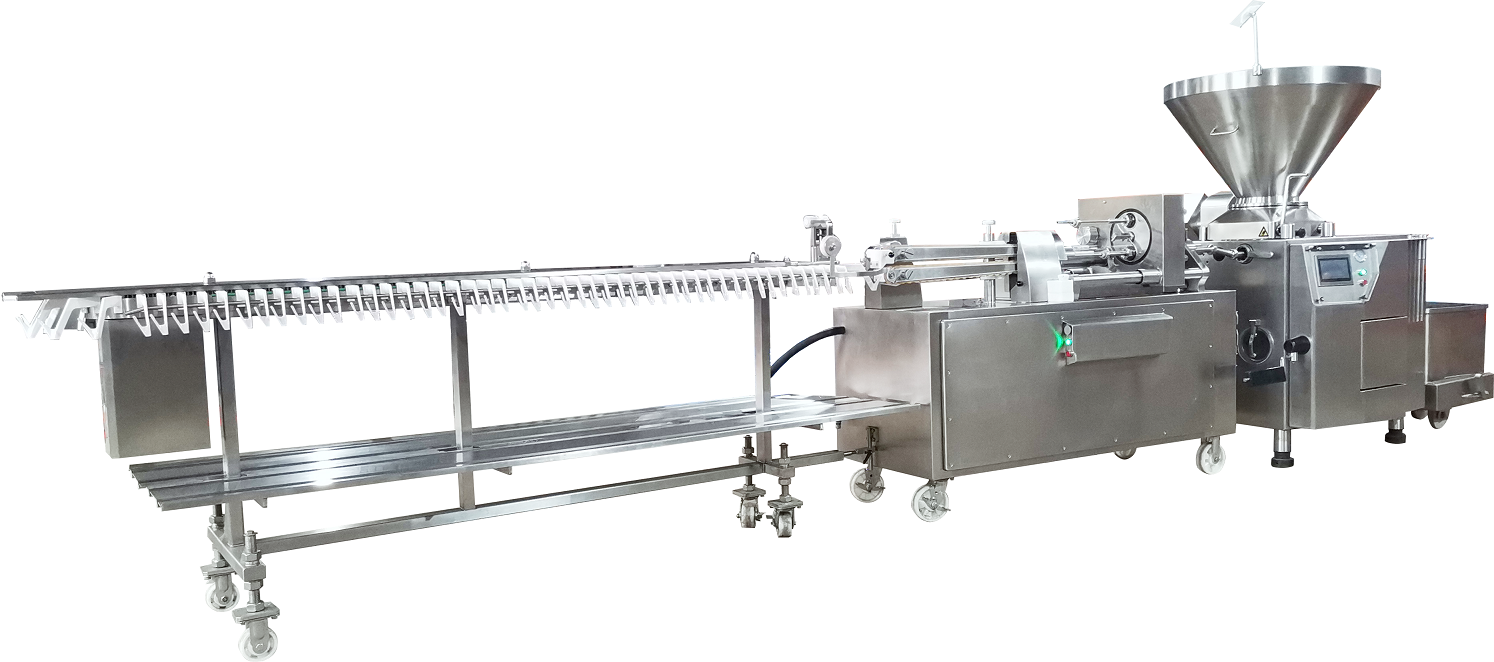

In the fast-paced world of food production, efficiency and quality are paramount. Among the various technologies that enhance these aspects, vacuum stuffing machines play a crucial role, particularly in meat processing and packaging. A vacuum stuffing machine factory specializes in the design and manufacture of these essential devices, ensuring that food products are not only appealing but also safe and preserved for longer periods.

Understanding Vacuum Stuffing Machines

Vacuum stuffing machines are designed to fill casings with a variety of products, including sausages, hams, and other meat products, while minimizing air exposure. By removing air from the stuffing process, these machines prevent oxidation and spoilage, which is vital for maintaining the quality and safety of the food. The vacuum technique also aids in achieving a consistent texture and shape, ensuring that the finished products meet consumer expectations.

The Manufacturing Process in a Vacuum Stuffing Machine Factory

The production of vacuum stuffing machines is a complex process that requires precision engineering and high-quality materials. A typical factory starts by sourcing durable components, such as stainless steel and food-grade plastics, known for their resistance to corrosion and ease of cleaning. These materials are essential for ensuring that the machines comply with health and safety regulations in food production.

Once the materials are ready, skilled technicians and engineers use advanced manufacturing techniques, including CNC machining, welding, and assembly, to create the machines. Quality control is an integral part of this process; each machine undergoes rigorous testing to ensure that it operates efficiently and meets the required performance standards.

Innovations in Vacuum Stuffing Technology

As the food industry evolves, so too do the technologies that support it. Vacuum stuffing machine factories are at the forefront of these innovations, continuously developing new features that enhance the functionality and usability of their products. For instance, modern vacuum stuffers may include programmable controls, allowing operators to customize filling speeds and pressures for different products. This flexibility is crucial for manufacturers who produce a diverse range of items.

vacuum stuffing machine factory

Moreover, advancements in materials science have led to the development of machines that are not only more efficient but also easier to clean and maintain. Features such as removable parts and stainless-steel construction ensure that food safety standards are upheld, which is vital in today’s health-conscious market.

Customization for Diverse Needs

One of the key advantages of a vacuum stuffing machine factory is its ability to offer customized solutions. Different clients have varying requirements based on the type of products they produce, their production scale, and specific regulatory compliance needs. A reputable factory will work closely with clients to design and manufacture machines that fit their unique operational needs.

This customization can include adaptations for different casing sizes, filling capacities, and even advanced vacuum technologies to enhance shelf-life preservation. By prioritizing client specifications, vacuum stuffing machine factories foster a collaborative relationship that benefits both parties.

Environmental Considerations and Sustainability

In recent years, sustainability has become a critical focus for many industries, including food production. Vacuum stuffing machine factories are increasingly adopting eco-friendly practices in their manufacturing processes. This includes using recycled materials, minimizing waste, and incorporating energy-efficient technologies in their machines. These efforts not only reduce the environmental impact but also appeal to a growing demographic of environmentally conscious consumers.

Conclusion

In summary, a vacuum stuffing machine factory embodies the intersection of innovation, quality, and sustainability in the food production sector. By leveraging advanced manufacturing techniques, customizing solutions to meet diverse needs, and focusing on environmentally friendly practices, these factories play a crucial role in ensuring that food products are produced efficiently and safely. As the demand for high-quality and safely packaged food continues to rise, the significance of vacuum stuffing machines and the commitment of their manufacturers become ever more prominent in driving industry standards and consumer satisfaction.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025