Frozen Meat Grinder JR130

Frozen Meat Grinder

1、 Applicable scope

This machine can chop frozen meat, boneless fresh meat, vegetables and other raw materials that are not lower than -8 ℃; Suitable for mass production in small and medium-sized enterprises.

2、 Working principle

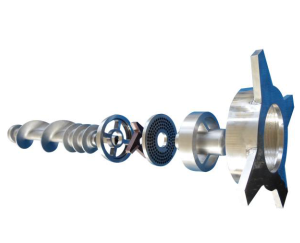

The machine mainly consists of an electric motor, a reducer, a frame, a hopper, a protective cover, a twisting sleeve, two twisting screws, and holes

Composed of board, cutter, locking sleeve, etc; When the meat grinder is working, it mainly relies on the rotating feeding and grinding dragon to push the raw materials in the hopper to the working grinding dragon. The working grinding dragon pushes the raw materials to the pre cutting hole plate, and uses the shearing effect formed by the rotating grinding blade and the holes on the hole plate to chop the meat. Under the squeezing pressure of the working grinding dragon, the meat particles are continuously discharged from the hole plate.

3、 Structural characteristics

- Layout diagram

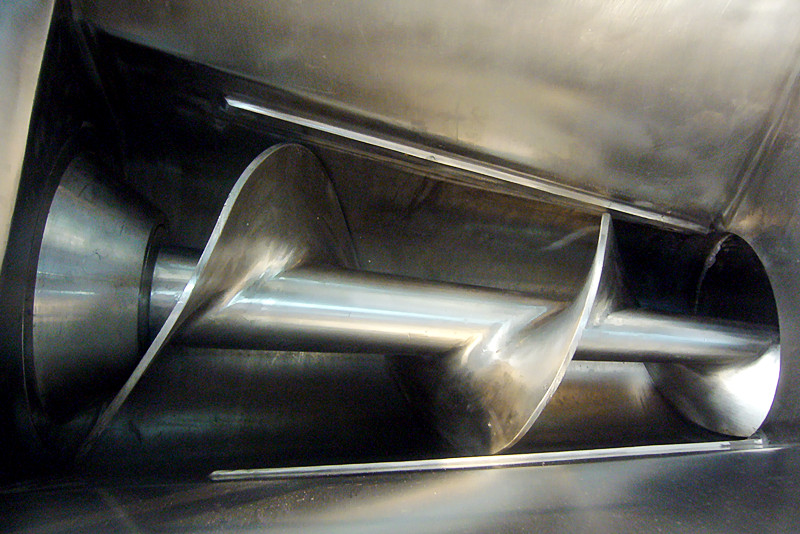

2.Equipped with a feeding winch and a working winch. Each twisting dragon works independently, with two speeds each, allowing for root movement

According to different raw materials, different speed ratios are used to improve product adaptability and production efficiency.

- Good particle size; The reasonable design of the screw pitch of the work twisting dragon enables the smooth passage of raw meat and reduces oil leakage

Elephant, and reduce the wear and tear of the meat by the twisting dragon, resulting in a low temperature rise of the meat and clear edges with good particle size.

- The work auger is finely processed, with a smooth surface to reduce material friction.

- The spiral design of the feeding twisting dragon cone ensures more complete feeding.

- There are various combinations of cutting tools that can meet various customer needs, such as grinding frozen meat, fresh meat, vegetables, etc.

- Equipped with a quick release handle and handle, it is easy to disassemble the work auger and cutting tools, making it easy to clean and disinfect.

- The bearing part is equipped with a protective device to prevent accidental damage to the bearing.

- The exterior is made of SUS304 stainless steel material, with a circular arc shape design that meets hygiene requirements.

- The cutting tools are made of imported materials and are interchangeable with European standard cutting tools.

- Equipped with a safety protection mechanism for safer operation.

4、 Technical parameters

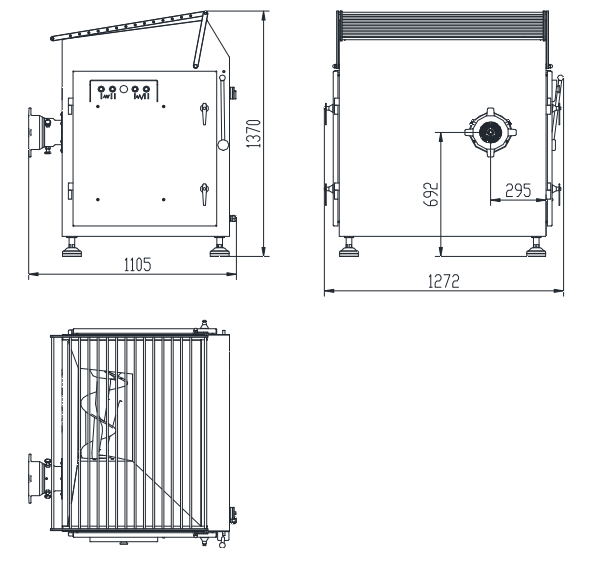

- Power supply: 380 V/50Hz, three-phase

- Total power: 19 kW

- Production capacity: MAX 3000 kg/H

- Knife disc diameter: 130 mm

- External dimensions: length x width x height=1250x1300x1400 mm

- Weight: Approximately 750kg

5、 General configuration

- Feeding drive: reducer drive manufacturer: Sanlian, Wannan Motor

- Main motor: Dual speed motor Manufacturer: Shandong Zhongtai

- Operation method: Button manufacturer: Konada

- Electrical box control components: mainly composed of Zhengtaiyuan components

- Bearing: Manufacturer: FAG

Fresh pork processing

Processed pig fat