Nov . 01, 2024 09:51 Back to list

hamburger molding machine manufacturers and production processes in the industry

The Evolution and Impact of Hamburger Molding Machine Factories

In the rapidly evolving food manufacturing sector, hamburger molding machine factories play a crucial role in enhancing the efficiency and quality of burger production. These specialized factories utilize advanced technologies to create uniform hamburger patties, ensuring consistency in taste and texture while optimizing production processes.

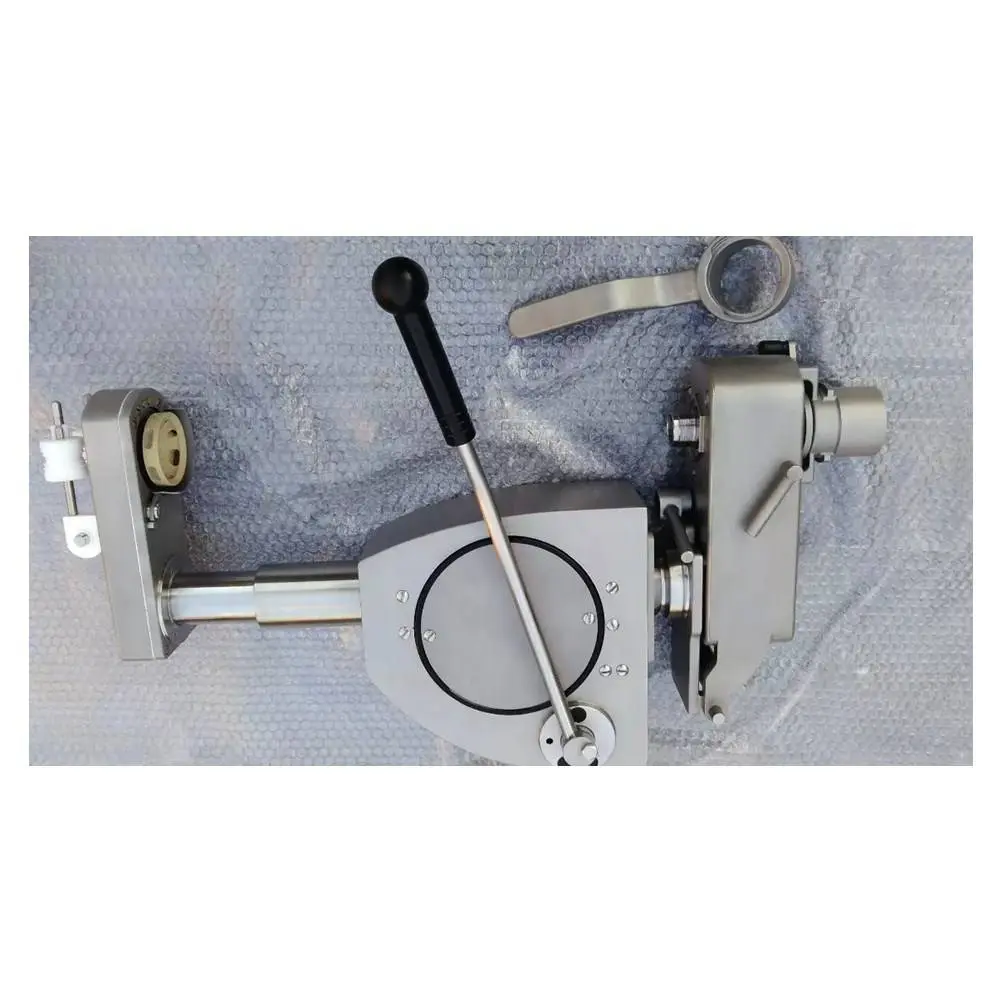

Historically, the production of hamburger patties was a labor-intensive task, often leading to discrepancies in size and weight. However, with the advent of hamburger molding machines, factories have been able to automate this process significantly. These machines use precise molds and adjustable settings to produce patties that meet specific weight and thickness requirements, addressing the needs of both large-scale food manufacturers and quick-service restaurants.

One of the key benefits of hamburger molding machine factories is the efficiency they bring to the production line. By reducing manual labor, these machines allow factories to operate at a faster pace, ultimately increasing output. This efficiency is particularly important in meeting the demands of a growing consumer base that craves fast and convenient meal options. Moreover, with the rising popularity of plant-based and alternative meat products, many factories have adapted their machinery to cater to different types of patties, ensuring that they remain relevant in an ever-changing market.

hamburger molding machine factories

Quality control is another significant advantage offered by hamburger molding machine factories. Equipped with state-of-the-art technologies, these machines can ensure that each patty produced meets stringent health and safety standards. This consistency not only enhances customer satisfaction but also builds trust in the brand as consumers increasingly prioritize hygiene and quality in their food choices.

Furthermore, the rise of sustainable practices within the food industry has prompted hamburger molding machine factories to innovate. Many factories are now investing in eco-friendly technologies, such as energy-efficient machines and recyclable materials for packaging. This shift not only reduces the carbon footprint of production but also appeals to environmentally conscious consumers, further boosting the factory's reputation.

Despite the advantages, the shift towards automation and reliance on machinery also presents challenges. The initial investment in high-tech molding machines can be substantial, and smaller factories may struggle to keep up with these costs. Additionally, there is a need for skilled operators who can manage and maintain these machines, creating a demand for specialized training in the workforce.

In conclusion, hamburger molding machine factories represent a significant advancement in the food manufacturing industry. Their ability to enhance efficiency, ensure quality, and adapt to changing market demands positions them as vital players in the global food supply chain. As technology continues to evolve, these factories are poised to further revolutionize hamburger production, catering to an ever-growing audience seeking convenience and quality in their dining experiences.