Dùbh . 11, 2024 21:45 Back to list

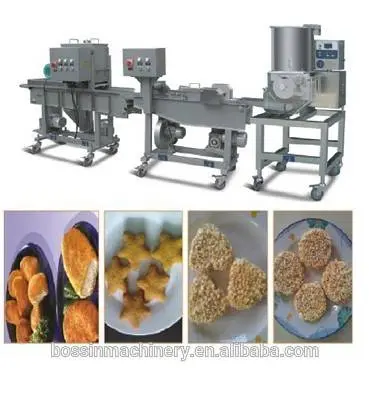

chicken breast meat flattening machine factories

The Role of Chicken Breast Meat Flattening Machines in Poultry Processing

In the ever-evolving landscape of the poultry industry, efficiency and quality have become paramount. Among the various pieces of machinery that facilitate the processing of chicken, the chicken breast meat flattening machine plays a crucial role. This innovative device not only enhances the quality of the final product but also streamlines operations in meat processing factories, resulting in increased productivity and reduced labor costs.

The Importance of Chicken Breast Meat Flattening

Chicken breast is one of the most popular cuts of poultry, known for its versatility, health benefits, and culinary appeal. However, to meet the demands of both chefs and consumers, chicken breasts often require specific preparation, which includes flattening. Flattening chicken breasts helps ensure uniform cooking, reduces cooking time, and creates aesthetically appealing presentations for dishes. The flattening process also facilitates marinating and seasoning, allowing flavors to permeate the meat more effectively.

In traditional settings, flattening required skilled labor and considerable time. However, the advent of specialized machinery has revolutionized this process. Chicken breast meat flattening machines have been designed to automate and optimize the flattening procedure, making it faster and more efficient without sacrificing quality.

Enhancing Efficiency in Meat Processing Factories

The incorporation of flattening machines in poultry processing factories represents a significant technological advancement. These machines can process large volumes of chicken breasts in a fraction of the time it would take manual laborers. Most flattening machines operate using mechanical or pneumatic systems that apply even pressure to the meat, ensuring consistent results every time.

The advantages of using chicken breast meat flattening machines are manifold

1. Time-Saving Automation significantly reduces the time required for flattening, allowing factories to increase their output and meet higher demand levels.

2. Consistency Machines provide uniformity in thickness, which is essential for even cooking. Consistent thickness ensures that every piece of meat cooks at the same rate, preventing overcooking or undercooking.

3. Labor Reduction By automating the flattening process, factories can decrease their reliance on manual labor. This not only reduces labor costs but also minimizes the risk of workplace injuries associated with repetitive tasks.

chicken breast meat flattening machine factories

4. Quality Control Modern machines often come equipped with settings that allow for adjustments based on the specific requirements of the product, ensuring high standards of quality control.

5. Hygiene Standards As food safety becomes increasingly important, machines can help maintain hygiene standards by reducing human contact with raw meat, thus mitigating contamination risks.

Choosing the Right Chicken Breast Meat Flattening Machine

With the surge in popularity of chicken breast meat flattening machines, several manufacturers have begun to offer diverse options tailored to meet the unique needs of different processing facilities. When selecting a machine, several factors should be considered

- Capacity Depending on the volume of production, factories need machines capable of handling their output requirements. Understanding the maximum and minimum processing capabilities is essential.

- Ease of Use User-friendly interfaces and easy maintenance are critical to ensure smooth operations and reduce downtime.

- Durability and Material Machines made from high-quality materials can withstand the rigors of daily use and are less likely to require frequent repairs.

- Cost While investing in automation can lead to long-term savings, it is essential to balance the initial costs with the expected benefits, including increased productivity and labor savings.

Conclusion

The introduction of chicken breast meat flattening machines has dramatically transformed poultry processing factories. As the demand for high-quality, uniformly processed chicken breasts continues to rise, these machines offer a solution that ensures efficiency, consistency, and safety. By automating the flattening process, factories not only enhance their operations but also improve the overall quality of the chicken products they deliver. As technology continues to advance, the possibilities for further innovations in poultry processing remain promising, marking an exciting future for the industry.

Latest news

-

Pneumatic Clipping Machine: Efficient and Reliable Solution for Industrial Applications|Precision Cutting, Durability

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Precision Cutting, High-Speed Operations

NewsJul.21,2025

-

Pneumatic Clipping Machine- Shijiazhuang Bossin Machinery|Precision Cutting&Industrial Efficiency

NewsJul.21,2025