Oct . 04, 2024 07:13 Back to list

automatic burger patty factories

The Rise of Automatic Burger Patty Factories

In the fast-paced world of food production, the demand for efficiency, consistency, and quality has never been greater. Among the innovations that have transformed the food industry, automatic burger patty factories stand out as a remarkable advancement. These high-tech facilities not only streamline the production process but also redefine how we think about food manufacturing.

The concept of automatic burger patty factories is rooted in the need to meet the ever-growing appetite for hamburgers. With millions of burgers consumed daily across the globe, the traditional methods of production can no longer keep up. Automated factories employ cutting-edge technology, enabling businesses to produce vast quantities of patties in a fraction of the time it would take using conventional methods.

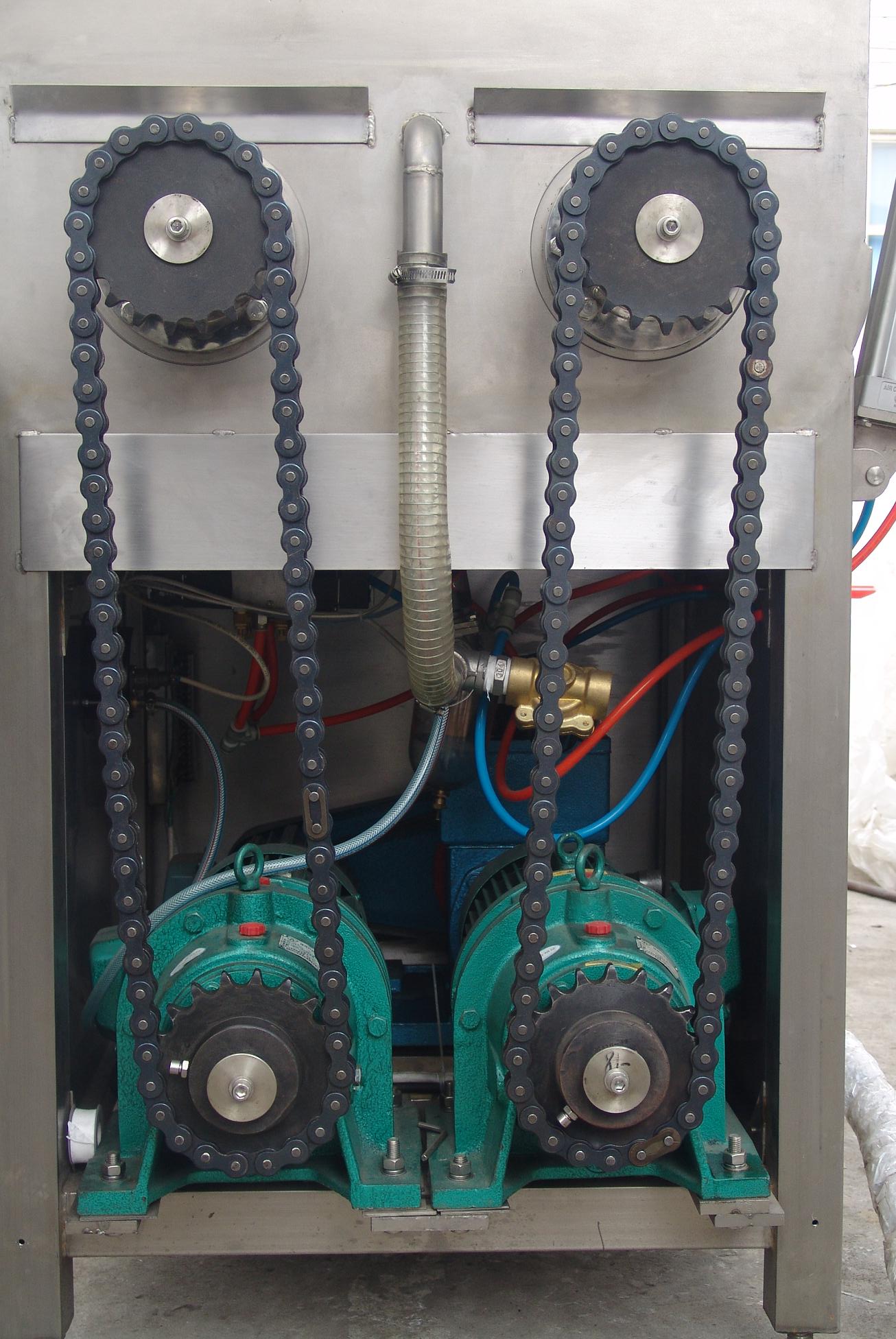

At the heart of these automated factories are intricate assembly lines equipped with advanced machinery. These machines can grind, mix, shape, and package meat with precision and speed. For example, high-capacity grinders break down cuts of beef into finely minced meat, while automated forming machines mold the meat into perfectly shaped patties. This level of automation not only enhances efficiency but also ensures uniformity in the size and thickness of each patty, which is crucial for maintaining quality across different batches.

Moreover, automatic burger patty factories implement stringent quality control measures. Sophisticated sensors and cameras monitor the production line, detecting any inconsistencies or contaminants. This real-time quality assurance helps prevent defective products from reaching the market, thereby protecting both the manufacturer’s reputation and consumer safety.

automatic burger patty factories

Sustainability is another vital aspect of modern burger patty production. Many automatic factories are designed with eco-friendliness in mind, incorporating energy-efficient machinery and sustainable practices. This could include utilizing by-products of meat processing, reducing food waste, and implementing water conservation techniques. As consumers become more environmentally conscious, factories that prioritize sustainability can gain a competitive edge in the market.

The economic implications of these factories are significant as well. By minimizing labor costs and maximizing output, companies can offer competitively priced products without compromising on quality. This efficiency ultimately benefits consumers through lower prices and wider availability of popular items like hamburgers.

However, the rise of automatic burger patty factories does raise some concerns. The increasing automation may lead to job displacement in traditional meat processing roles. While these factories create new opportunities in technology and maintenance, there is a need for workforce training and transition programs to support workers affected by these changes.

In conclusion, automatic burger patty factories represent a significant evolution in food production. With the integration of advanced technology, emphasis on quality control, and commitment to sustainability, these factories are reshaping the hamburger industry. While they bring undeniable benefits, it is essential to address the challenges they pose to the workforce. As we move forward, the focus must remain on how to harness these advancements for the betterment of both the industry and society as a whole.

Latest news

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Sausage Production Line Integration&Compact Design

NewsAug.06,2025

-

Automatic Deboner Machine for High-Yield Processing

NewsAug.06,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Precision and Efficiency

NewsAug.06,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsAug.06,2025

-

Pneumatic Clipping Machine- Shijiazhuang Bossin Machinery|Sausage Production Line, Food Processing Machinery

NewsAug.05,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Precision, Efficiency, Durability

NewsAug.05,2025