Mar . 04, 2025 02:25 Back to list

wholesale stainless steel filler

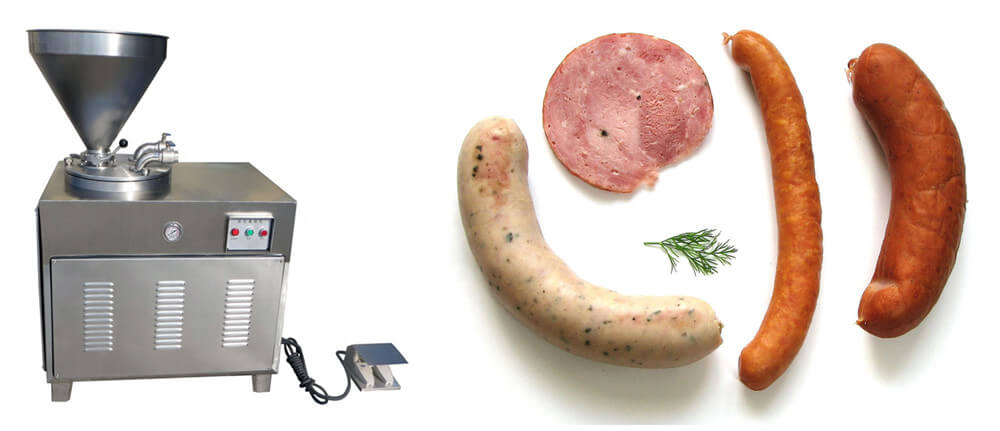

For businesses in industries that require durability, corrosion resistance, and aesthetic appeal, wholesale stainless steel filler options are indispensable. These products serve a myriad of industries, from construction and automotive to food processing and medical equipment manufacturing. Understanding the nuances of choosing the right stainless steel filler can significantly boost product longevity and performance.

Another crucial aspect for businesses is staying informed about the latest advancements in stainless steel filler technology. The development of newer alloys and filler formulations designed to achieve specific results, such as enhanced high-temperature resistance or improved ductility, can give businesses a competitive edge. Therefore, associating with a supplier engaged in research and innovation within the stainless steel industry ensures access to the most up-to-date products. In the realm of quality assurance, certifications play a decisive role. Ensuring that your supplier is ISO certified or holds other relevant certifications is vital. These certifications are testimonials to the supplier’s adherence to international quality standards and impeccable manufacturing practices. Moreover, in today’s digital age, building a rapport with wholesale stainless steel filler suppliers often extends beyond traditional methods. A robust online presence, encompassing well-structured websites that offer comprehensive product catalogs, customer reviews, and easy-to-navigate interfaces, is indicative of a supplier's credibility. Suppliers who invest in their digital platforms are often more accessible, providing real-time updates and support—an invaluable resource for facilitating efficient supply chain management. In summary, the choice of wholesale stainless steel filler should integrate cost-efficiency, product range, technical support, and an updated knowledge base. By selecting a supplier with proven expertise, businesses can ensure higher quality outputs and build sustainable operations that withstand the rigors of their specific environments. Trust, built on a foundation of reliability, specialization, and customer-centricity, ultimately fosters long-lasting partnerships that propel industry standards and innovation.

Another crucial aspect for businesses is staying informed about the latest advancements in stainless steel filler technology. The development of newer alloys and filler formulations designed to achieve specific results, such as enhanced high-temperature resistance or improved ductility, can give businesses a competitive edge. Therefore, associating with a supplier engaged in research and innovation within the stainless steel industry ensures access to the most up-to-date products. In the realm of quality assurance, certifications play a decisive role. Ensuring that your supplier is ISO certified or holds other relevant certifications is vital. These certifications are testimonials to the supplier’s adherence to international quality standards and impeccable manufacturing practices. Moreover, in today’s digital age, building a rapport with wholesale stainless steel filler suppliers often extends beyond traditional methods. A robust online presence, encompassing well-structured websites that offer comprehensive product catalogs, customer reviews, and easy-to-navigate interfaces, is indicative of a supplier's credibility. Suppliers who invest in their digital platforms are often more accessible, providing real-time updates and support—an invaluable resource for facilitating efficient supply chain management. In summary, the choice of wholesale stainless steel filler should integrate cost-efficiency, product range, technical support, and an updated knowledge base. By selecting a supplier with proven expertise, businesses can ensure higher quality outputs and build sustainable operations that withstand the rigors of their specific environments. Trust, built on a foundation of reliability, specialization, and customer-centricity, ultimately fosters long-lasting partnerships that propel industry standards and innovation.

Latest news

-

Vacuum Slider with GPT-4 Turbo Precision Motion Control

NewsAug.02,2025

-

Linking Gearbox & Holding Device with GPT-4-Turbo AI

NewsAug.01,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Precision Clipping, Automated Sausage Production

NewsAug.01,2025

-

Ultimate Vacuum Filler: AI-Powered Sealing Efficiency

NewsJul.31,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsJul.31,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Automated Sausage Clipping&Modular Design

NewsJul.31,2025