נוב . 13, 2024 01:23 Back to list

chicken debone machine supplier

The Rise of Chicken Debone Machine Suppliers Revolutionizing Poultry Processing

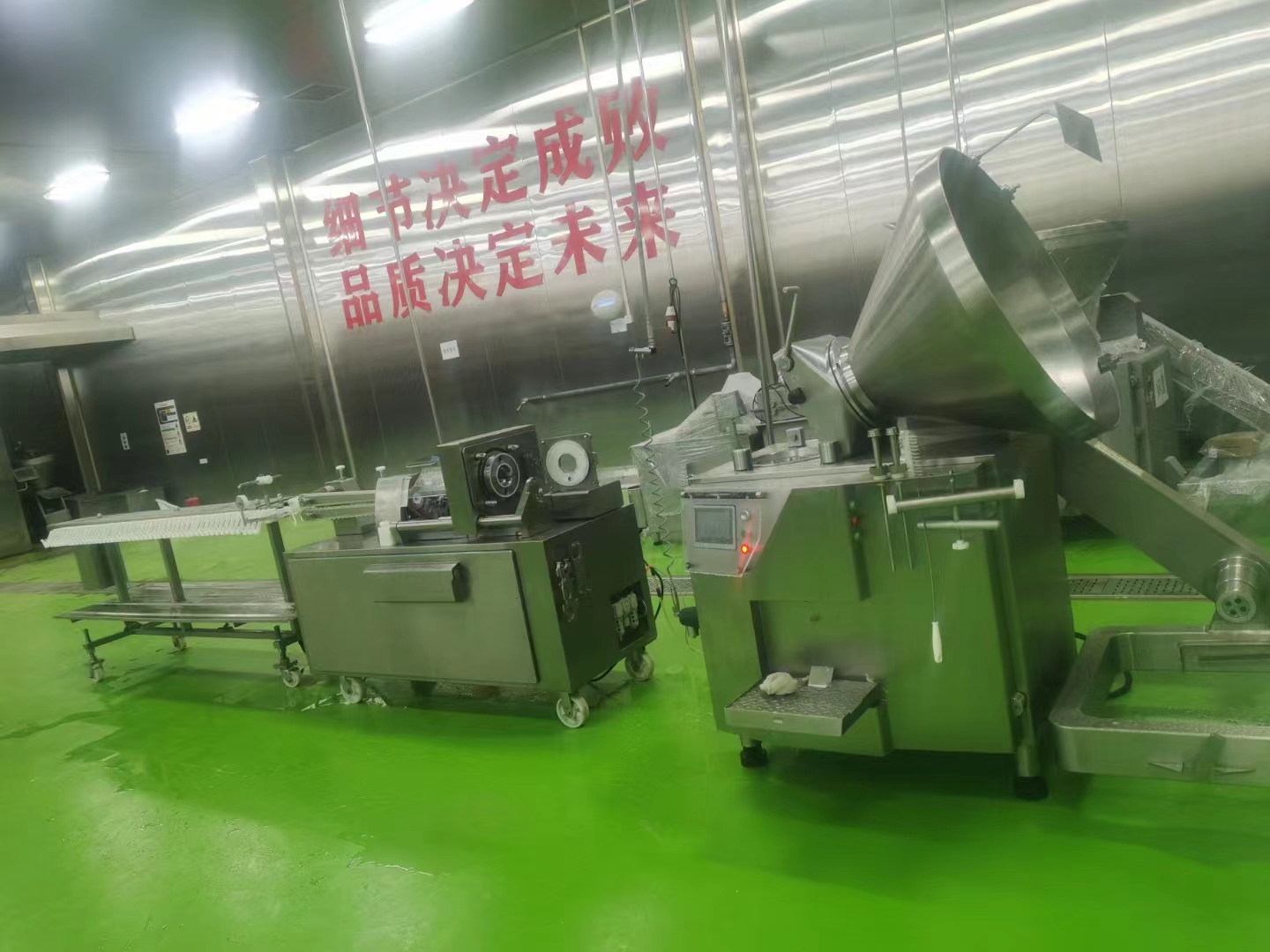

In the realm of modern poultry processing, the demand for efficiency, quality, and hygiene is greater than ever. As the global marketplace expands, processors are striving to meet customer expectations while maximizing profitability. One of the key innovations that have emerged in this industry is the chicken debone machine, and an array of suppliers have stepped up to meet this need. This article explores the significance of chicken debone machine suppliers, the advantages of using these machines, and trends shaping the future of poultry processing.

The Importance of Deboning Machinery

Traditional methods of deboning chicken can be labor-intensive, time-consuming, and prone to human error. With fluctuating labor costs and the increasing demand for processed chicken products, it has become essential for poultry processors to adopt automated solutions. Chicken debone machines simplify the deboning process, improving both efficiency and accuracy. These machines are designed to remove bones from various chicken parts, such as breasts, thighs, and drumsticks, enhancing product quality and consistency.

Advantages of Using Debone Machines

1. Enhanced Efficiency Chicken debone machines significantly speed up production, enabling processors to handle larger volumes of poultry in shorter periods. This efficiency not only meets consumer demand but also increases overall output, leading to improved profit margins.

2. Consistency and Quality Automated deboning results in uniformity across batches, ensuring that each piece of chicken is deboned to the same standard. This consistency in quality is paramount in meeting safety regulations and satisfying customer preferences.

3. Labor Savings Investing in deboning machines reduces the reliance on manual labor, allowing companies to reallocate their workforce to other critical areas. In an era when skilled labor shortages are common, automation presents a viable solution.

4. Hygiene and Safety Automation minimizes human contact with raw chicken, reducing the risk of contamination. This aspect is particularly crucial in an industry that faces stringent food safety regulations.

5. Adaptability and Flexibility Many chicken debone machines are designed to handle different types of poultry and can be easily adjusted for various sizes and cuts. This versatility ensures that suppliers can cater to diverse market needs.

chicken debone machine supplier

The Role of Suppliers

As the demand for chicken debone machines grows, suppliers play a pivotal role in the industry. They provide not only the equipment but also vital services such as installation, maintenance, and technical support. A reputable supplier will ensure that processors are equipped with the latest machinery that incorporates cutting-edge technology to optimize performance. Furthermore, many suppliers are focusing on sustainability, offering machines that reduce waste and energy consumption.

Trends Shaping the Future

The poultry processing industry is evolving, driven by technological advancements and changing consumer behaviors. Here are a few key trends

1. Integration of Smart Technology Suppliers are increasingly incorporating IoT (Internet of Things) technology into debone machines. This integration allows for real-time monitoring of machines, predictive maintenance, and data analysis to optimize operations.

2. Sustainable Practices With growing environmental awareness, both consumers and regulators are urging the poultry industry to adopt sustainable practices. Suppliers are responding by developing energy-efficient machines and technologies that minimize waste.

3. Customization and Personalization As the market shifts towards more personalized food products, suppliers are offering customized deboning solutions that can accommodate unique customer requests, such as specific cuts or portion sizes.

4. Globalization of Supply Chains The globalization of the poultry market means that suppliers must be responsive to changing regulations and consumer preferences across different regions. This global reach requires adaptability and innovation in product offerings.

Conclusion

The emergence of chicken debone machine suppliers marks a transformative period for the poultry processing industry, driven by the need for efficiency, quality, and safety. By automating the deboning process, these suppliers not only help processors meet the increasing demand for poultry products but also pave the way for a more sustainable and technologically advanced future. As the industry continues to evolve, the collaboration between processors and suppliers will be crucial to navigating challenges and embracing opportunities in the global market.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025