נוב . 16, 2024 02:37 Back to list

rolling machine supplier

The Importance of Selecting the Right Rolling Machine Supplier

In modern manufacturing and metalworking industries, rolling machines play a crucial role in shaping and forming metal sheets and various materials. These machines are essential for producing components that require specific dimensions and tolerances, which are vital for various applications. Therefore, choosing the right rolling machine supplier becomes a pivotal decision for businesses looking to optimize their production processes. This article discusses the significance of selecting a reliable rolling machine supplier and what factors to consider in the selection process.

Understanding the Role of Rolling Machines

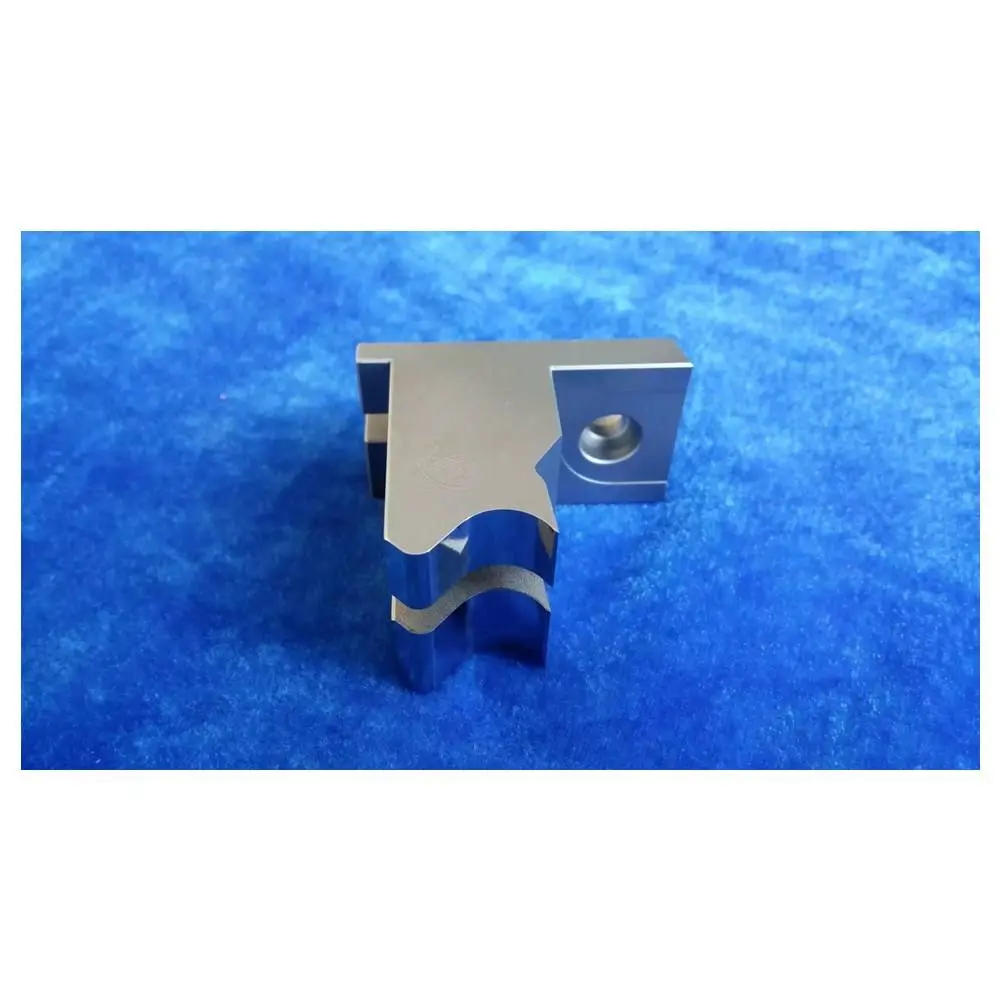

Rolling machines are used to manipulate metals through various processes, including bending, shaping, and forming. They come in various types, including plate rolling machines, section rolling machines, and tube rolling machines, each designed for specific applications. The quality and capabilities of a rolling machine directly impact production efficiency, material wastage, and the accuracy of the finished products. Consequently, investing in top-tier equipment from a reputable supplier is essential for any manufacturing operation.

The Need for a Reliable Supplier

Selecting a reliable rolling machine supplier is crucial for several reasons

1. Quality of Equipment A trustworthy supplier will offer high-quality machines that meet industry standards. Quality rolling machines are not only more efficient but also have a longer lifespan, which contributes to the overall cost-effectiveness of production.

2. Technical Support and Maintenance A good supplier will provide excellent after-sales support, including maintenance services and technical training. This support is vital for minimizing downtime and ensuring that machines operate at optimal efficiency.

3. Customization Options Every manufacturing operation has unique requirements. A capable supplier will offer customized solutions tailored to specific needs, ensuring that the rolling machines can handle the desired processes effectively.

4. Innovative Technology The manufacturing industry is continually evolving, with new technologies enhancing efficiency and productivity. A reputable supplier will stay updated on the latest advancements and offer machines equipped with innovative features that provide a competitive edge.

5. Reputation and Experience The reputation of a supplier can often be gauged by their experience in the industry. A supplier with years of experience is more likely to understand the specific challenges faced by manufacturers and provide appropriate solutions.

rolling machine supplier

6. Cost-Effectiveness While it may be tempting to choose the cheapest option available, it is essential to consider the long-term costs associated with lower-quality machines. A well-built rolling machine may have a higher upfront price but could save money in maintenance, energy consumption, and production efficiency over time.

Factors to Consider When Selecting a Supplier

When choosing a rolling machine supplier, several factors should be taken into account

- Product Range Assess the variety of rolling machines offered. A supplier with a wide range of models is likely to cater to diverse needs.

- Customer Reviews and Testimonials Research feedback from previous customers to gauge satisfaction levels. Positive testimonials can indicate the reliability and quality of the supplier's equipment and service.

- Warranty and Service Agreements A solid warranty and comprehensive service agreements are indications of a supplier's confidence in their products. Ensure that any potential supplier offers adequate protection against defects and breakdowns.

- Delivery and Installation Consider the supplier's ability to deliver and install the machines promptly. Delays in installation can significantly affect production timelines.

- Location Depending on your location, it may be beneficial to choose a supplier that is geographically close. Proximity can enhance communication and reduce shipping times.

Conclusion

In conclusion, the selection of a rolling machine supplier is a strategic decision that can significantly influence the success of manufacturing operations. By prioritizing factors such as quality, support, experience, and customization, businesses can find a supplier that not only meets their immediate needs but also contributes to long-term success. Investing time and resources into finding the right supplier will undoubtedly pay off in increased efficiency, product quality, and overall competitiveness in the marketplace. As the industry continues to evolve, staying ahead with the right equipment and support is essential for success in a rapidly changing landscape.