सितम्बर . 19, 2024 16:57 Back to list

meat machine factories

The Evolution of Meat Machine Factories

In the modern era, the meat industry has undergone significant transformations, primarily driven by advancements in technology and shifting consumer demands. Central to this evolution are meat machine factories, which play a crucial role in processing meat products efficiently and safely.

Meat machine factories specialize in the production and assembly of machinery designed for various stages of the meat processing chain. From initial butchering and cutting to packaging and preserving, these machines are engineered to streamline operations and improve productivity. Key innovations include automated cutting machines, vacuum sealers, and conveyor systems that enhance the speed and efficiency of meat production. As technology continues to advance, these factories are incorporating smart technologies like IoT (Internet of Things) to monitor production processes in real-time, ensuring better quality control and minimizing waste.

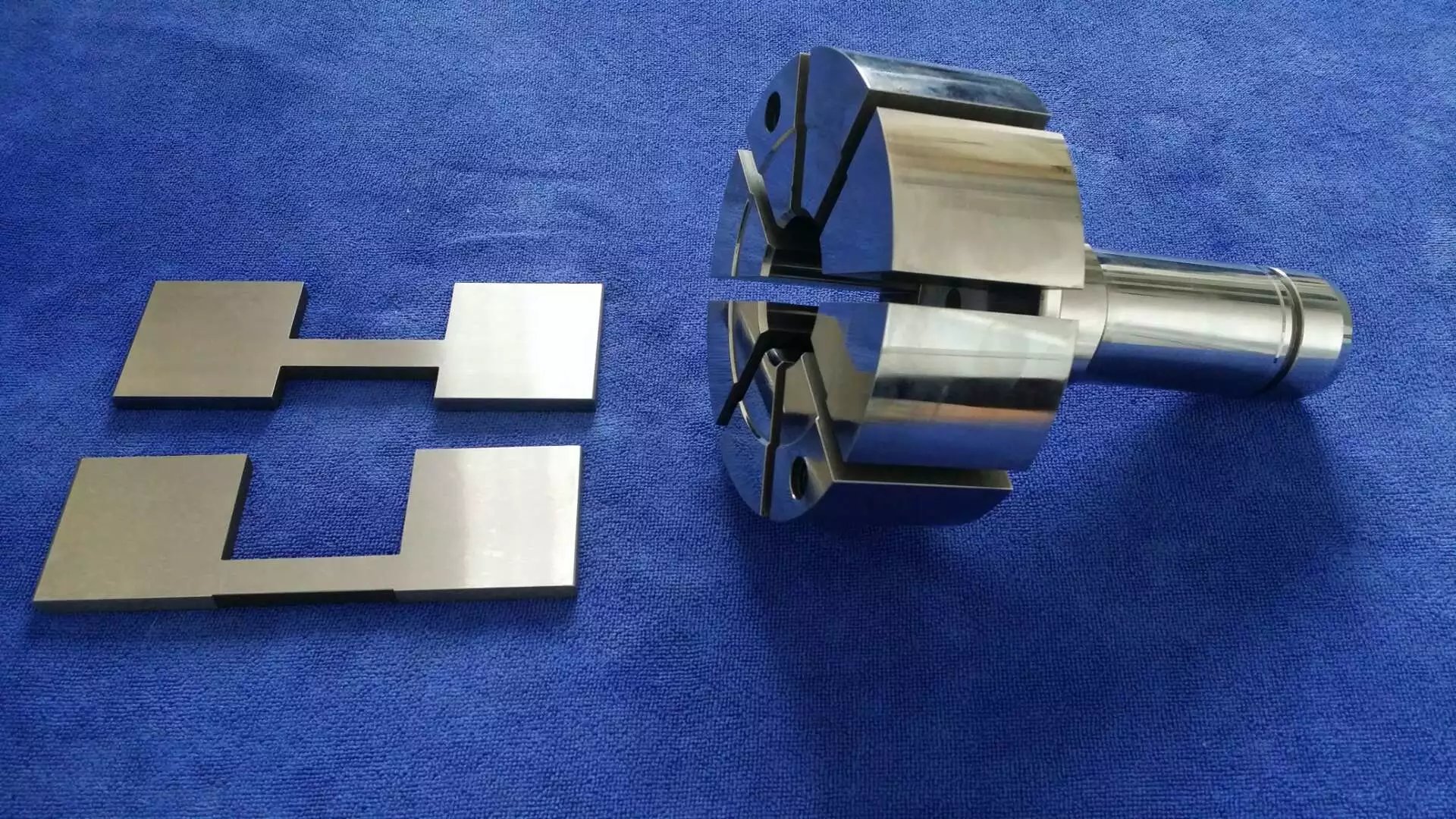

An essential aspect of meat machine factories is their commitment to food safety. With increasing regulations surrounding food products, these factories invest in developing machines that adhere to stringent quality standards. The use of stainless steel components and hygienic designs reduces the risk of contamination, ensuring that meat products are safe for consumers. Additionally, factories are implementing traceability systems that allow for tracking meat products from the source to the retailer, enhancing transparency in the supply chain.

meat machine factories

The rise of plant-based diets and ethical concerns surrounding meat consumption has also influenced the operations of meat machine factories. In response, many factories are diversifying their offerings by incorporating machinery that can process alternative proteins, such as soy and pea-based products. This shift not only meets consumer demands for sustainable options but also reflects a broader trend towards balancing meat production with environmental considerations.

Furthermore, the labor landscape within these factories is evolving. Automation in meat production has led to changes in workforce requirements. While some tasks have been streamlined through machines, there is a growing need for skilled workers who can operate and maintain these advanced technologies. As a result, training programs and educational initiatives are increasingly important to ensure that the workforce is equipped with the necessary skills for the future.

In conclusion, meat machine factories are at the forefront of an evolving industry. Their role in improving efficiency, ensuring food safety, and adapting to changing consumer preferences underscores their importance in the meat supply chain. As the industry continues to face challenges, including ethical concerns and environmental impacts, these factories will need to innovate and adapt to meet the demands of a dynamic marketplace. Through technology and a commitment to quality, meat machine factories are poised to shape the future of the meat industry for years to come.