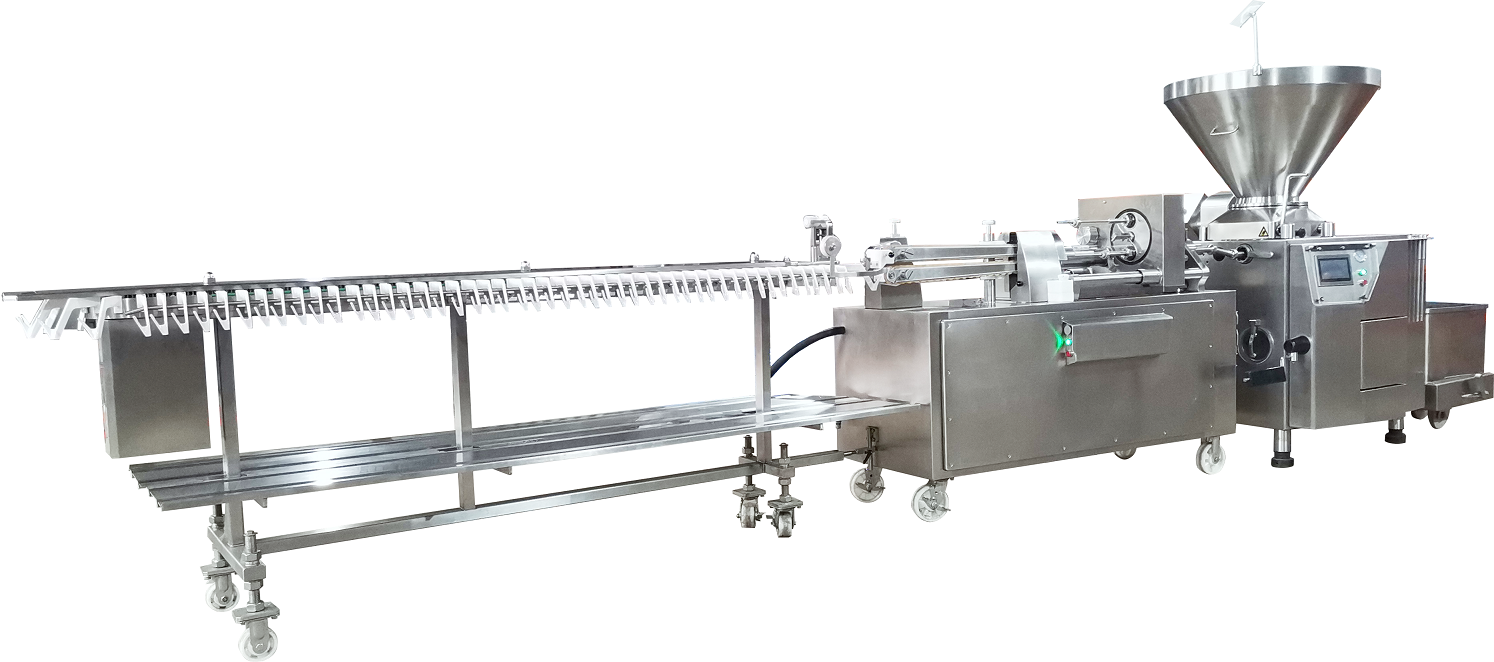

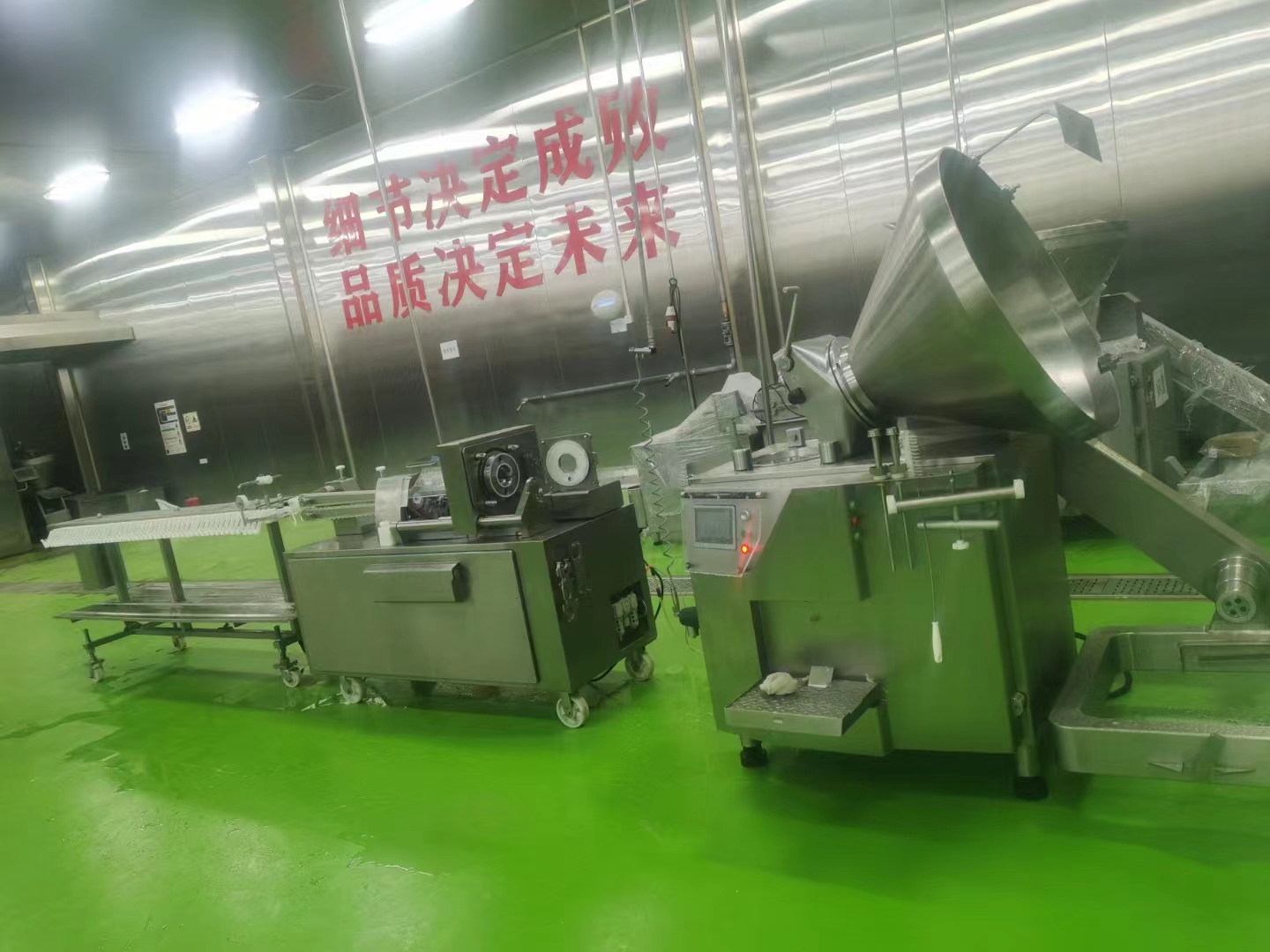

High speed Sausage filler-linker-hanger line

- THis sausage filling line, is composed by vacuum filler , linker, hanger three machines.

- VACUUM FILLER (with hydraulic lifter , no linking device)

- GC9plus-a vacuum filling machine is made of high-quality 304 stainless steel, which is durable and easy to clean. It fully meets the requirements of food safety and is suitable for filling products in all industries (except liquid filling). This equipment has reasonable overall structure, beautiful appearance, stable performance, simple operation and convenient maintenance. The maximum direct filling capacity of gc9plus-a is 6500kg / h, the outlet pressure of the filling machine is 40 bar, the filling machine is driven by a servo motor through a reduction gear box, and the feeding auger and the main shaft are driven by power distribution through gear shafts at all levels; The gears of the reducer are all hard surface gears, with precise transmission and high efficiency; The gears and bearings at all levels of the reducer are lubricated by the lubricating oil provided by the built-in gear oil pump through the oil filter to ensure the service life of the reducer; The shaft seal of the main shaft uses two seals to form a sealing cavity. Food grade grease is injected into the cavity through the external oil nozzle for lubrication. The waste grease is discharged to the outside of the equipment through the pipeline, which makes it convenient to inject grease; The servo motor is equipped with a 20 bit incremental encoder to ensure the electrical control accuracy of the equipment; The vacuum system adopts Germany puxu high vacuum ra40 vacuum pump. The vacuum slide valve automatically controls the opening of the vacuum channel, so that the filling will not flow into the vacuum pump even when the filling is very thin. The main components of the equipment, such as the cavity, rotor, blade, cam and main shaft of the vane pump, are made of high-quality alloy steel, with high machining accuracy, good wear resistance, long-term quantitative accuracy and long service life. The equipment is also equipped with a scraper, which is simple and convenient to clean the stuffing. The outlet is large, which can fill thicker or larger fillings. The machine has its own hoist, and the feeding is clean and fast with a 200 liter standard feeder truck. This machine can be connected with the punch card machines of various manufacturers to realize automatic production. Touch screen operating system, Chinese and English interfaces are interchangeable, and the operation is convenient and reliable. There are programs for direct filling, quantitative filling, quantitative kinking, and connecting punch. The new Internet of things function of the device can monitor the operation of the device in real time, which is convenient and fast

Advantages:

- The equipment is made of high-quality 304 stainless steel, which is beautiful, strong and durable.

- The structure design of the equipment is reasonable, especially the reducer part, which is self-designed and has a long service life.

- All parts are processed by CNC processing equipment with high precision and long service life.

- Accurate quantitative and long-term maintenance, good sealing and low cost in later use.

- The equipment is equipped with the latest stainless steel case kink device, which has excellent structure, simple and convenient operation, strong and durable, few vulnerable parts and convenient maintenance. It not only reduces the labor of front-line operators, but also greatly reduces the use cost of customers in the later stage, and it is interchangeable with the vulnerable parts of imported kinks of the same type.

- The new kink device can kink collagen casings, cellulose casings, various natural casings and other mainstream casings.

- The original German puxu high vacuum vacuum pump is used, with a maximum working pressure of 0.1mbar, which effectively extends the shelf life of the product.

- The electrical part has the Internet of things function, and the operation of the equipment can be remotely controlled, real-time and convenient.

- The sanitary condition is excellent, without sanitary dead ends, and easy to maintain.

GC9plus-A vacuum filling machine parameters

1) Power specification: three phase 380V AC

2) Total power: 10 kW

3) Filling accuracy ± 1% (based on 100g of minced product)

4) Maximum direct displacement: 6500 kg / h

5) Maximum outlet pressure of meat pump: 40bar

6) Mechanical dimension: 1880 * 1369 * 2226mm

7) Machine weight: about 1300 kg

8) Body material: 304 stainless steel plate is used for welding. The wall thickness is 4mm, and the measured value is not less than 3.8mm (except for the front cover, electrical installation and other parts that do not play a supporting role)

9) Hopper volume: 250L

10) Online requirements: it can be used online with poly card punch card machines and punch card machines of domestic manufacturers.

11) Meat pump type: vane pump driven by servo motor

12) Filling center opening height: 993mm-1050mm adjustable

13) Double chain hoist ensures stable lifting of the hopper car.

14) This machine has Internet of things function.

GC9plus-A is improved on the basis of imported vf620 model. It has better sealing performance, faster speed and 20% larger displacement. It is favored by customers with large output!

2.SGDCFF-A high speed double-pipe Fixed length dividing machine (LINKER)

-2.1 maximum speed: 2000 knots / min (depending on product specifications and casing quality); The unique fixed length transmission system realizes more accurate product length control, weight control, tightness control and wider casing adaptability;

-2.2 the high-speed double tube fixed length batching machine can realize stable length control, weight control and tightness control of sausage under the computer control of quantitative batching according to production needs, and the length of sausage can be adjusted steplessly.

-2.3 production speed: the production speed of 4-5cm products can reach 1200 knots / min, and that of 12-18cm products is more than 500 knots / min. For Chinese sausage with 60g weight and 22mm caliber protein casings, the speed of the kinking machine shall not be lower than 500ppm;

-2.4 the high-speed fixed length dividing machine can be connected with the Gencheng vacuum enema machine, and can form a production line with Handtmann, Vemag or domestic high-performance filling machines;

-2.5 rotary double tube switching structure, alternate continuous filling, shorten the pause time of upper casing, and improve production efficiency;

-2.6 the high-speed fixed length dividing machine can steplessly adjust the enema length according to the production demand, and the fixed length twisting (the product length can be slightly adjusted to better meet the customer's requirements for product length and tightness);

-2.7 the use of high-speed fixed length dividing machine can reduce the burst of casings, and protein casings are suitable for domestic and imported casings;

-2.8 driven by servo motor, high speed and low noise;

-2.9 the applicable casing diameter range is 13-34mm (the suitable intestine pincher butterfly wheel is selected according to different casing diameters), and the split length range is 20-700mm;

-2.10 the intestinal clamp is equipped with a set of butterfly wheels, Linking tubes and supporting components. One set is selected according to the customer's products

-2.11 power consumption: 4.2kW, 380-400v, 50Hz, electrical protection grade IP65;

-2.12 the propeller with automatic casing is equipped with photoelectric induction. The casing detection can be switched by the propeller or photoelectric induction. When the casing is used up, it can stop automatically.

3. GCXG-A: HANGER

-3.1 the automatic suspension device is applicable to the automatic suspension of natural casings, collagen, and artificial casings and sausages, and can be connected with sgdcff-a root forming high-speed double tube fixed length dividing machine;

-3.2 the automatic rod hanging machine is controlled by the industrial computer, which can set the steps and the number of sausages hanging on each hook, and adjust the hook spacing to suit the hanging of sausages of different sizes;

-3.3 the speed of the hanging rod and the speed of the twisting joint of the enema are automatically matched;

-3.4 rated power: 1.0kw;

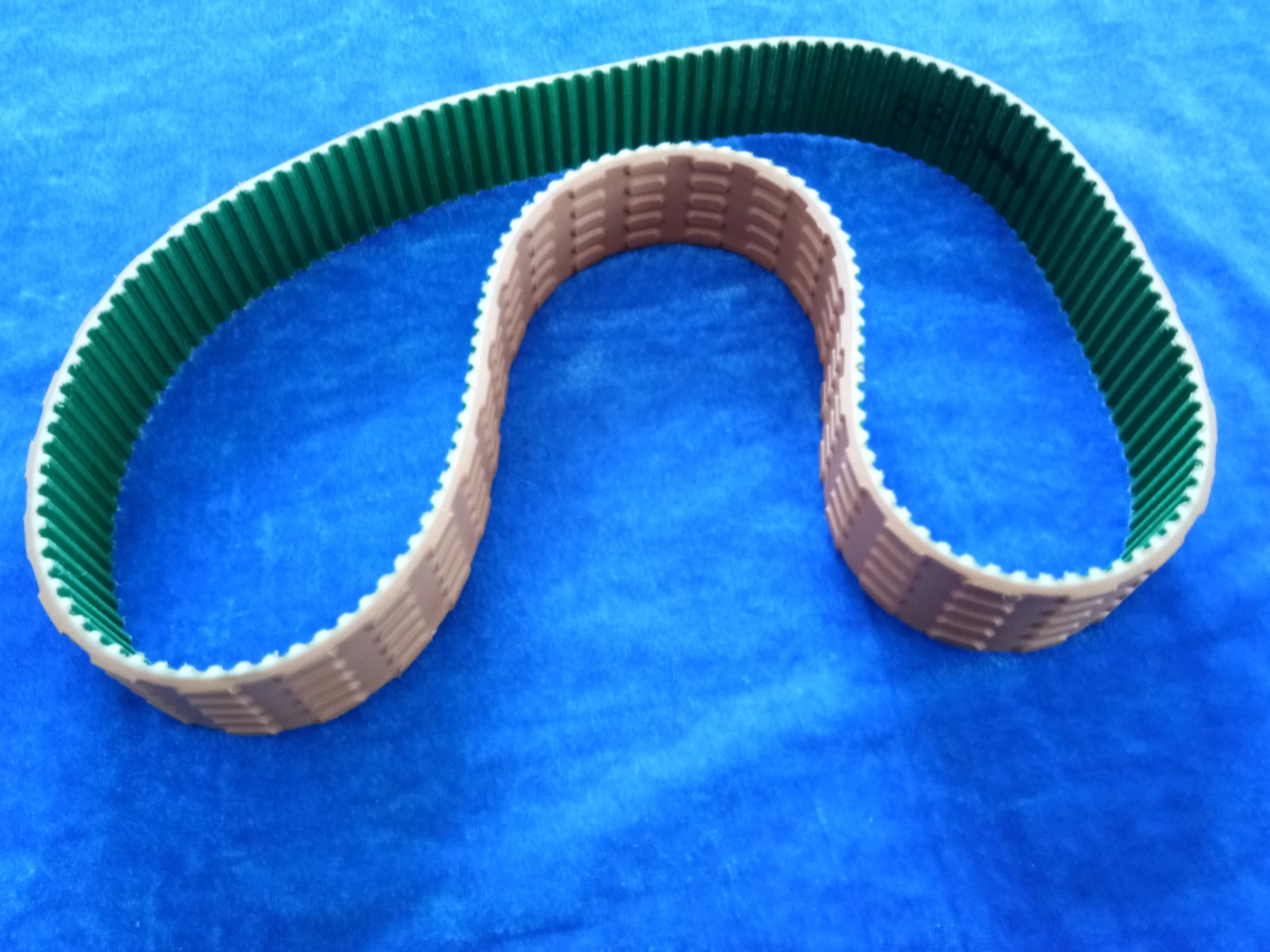

-3.5 chain drive is adopted, which is firm and not easy to be damaged;

-3.6 the hook distance starts from 25mm, and there is no limit to the variable distance;

-3.7 maximum speed: 200 hooks / min.