Nov . 17, 2024 00:48 Back to list

fresh meat slicer factory

The Fresh Meat Slicer Factory Precision, Quality, and Innovation

In the modern culinary landscape, the importance of precision and efficiency cannot be overstated. As restaurants and food suppliers strive to cater to an increasingly discerning clientele, the tools they use become paramount. Among these, fresh meat slicers stand out as essential equipment in any kitchen, butcher shop, or processing facility. Behind these indispensable devices lies a dedicated industry focused on producing high-quality meat slicers—let’s delve into the world of the fresh meat slicer factory.

The Manufacturing Process

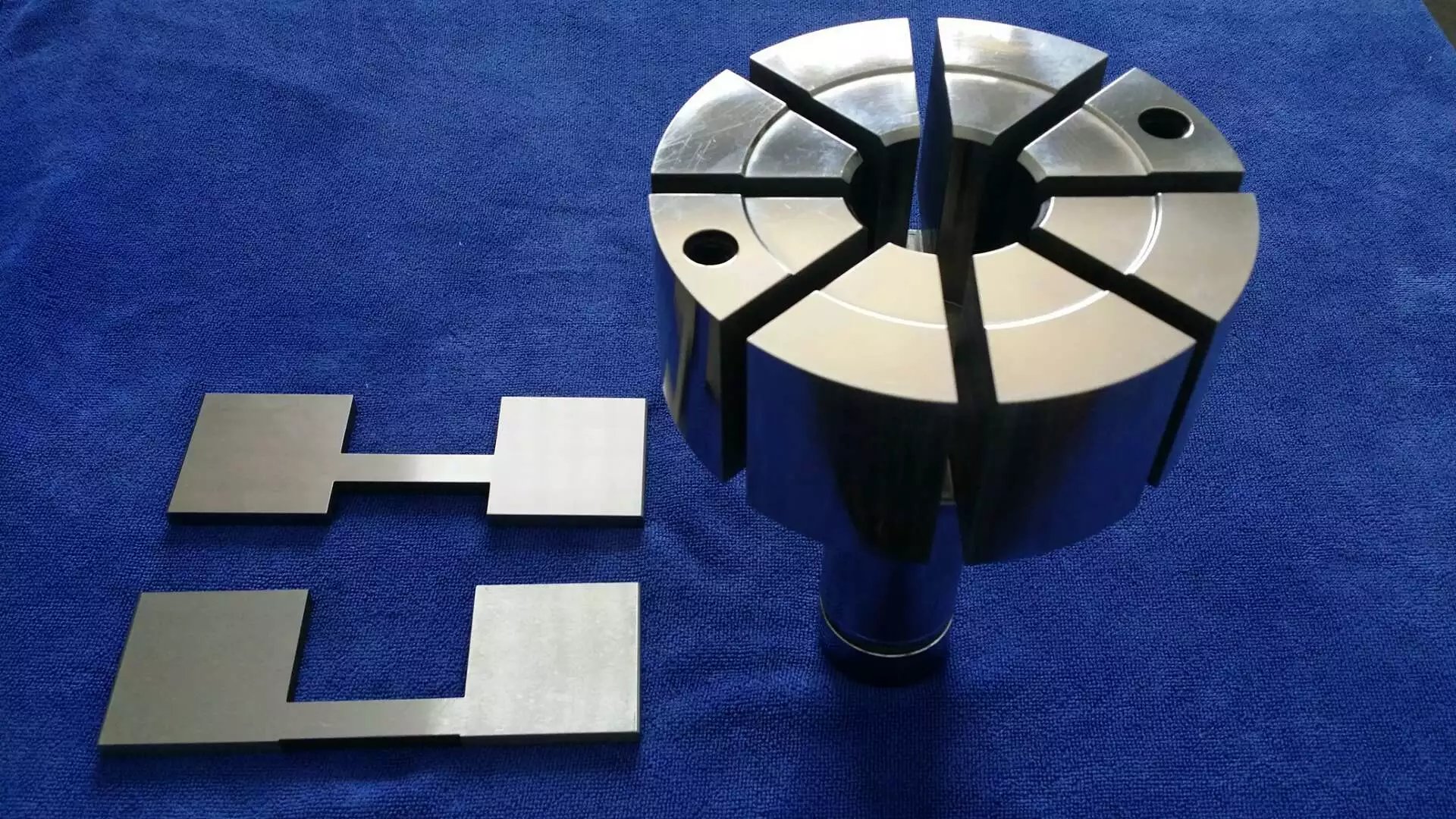

The journey of creating a fresh meat slicer begins with the selection of high-grade materials. Stainless steel is the predominant choice due to its durability, resistance to corrosion, and ease of cleaning. The manufacturing process involves several stages, including cutting, shaping, assembling, and finishing. Initially, sheets of stainless steel are cut to shape using advanced laser machines ensuring precision and consistency.

Subsequently, these components are shaped using various machining techniques. Computer Numerical Control (CNC) machines are commonly employed to create intricately designed parts that will fit together seamlessly. Precision is crucial; even a slight deviation can affect the slicer's performance.

Once the components are shaped, they undergo assembly. Skilled technicians meticulously bring together the motor, blade, and housing. Safety features are integrated at this stage, which is essential when dealing with sharp blades and high-speed machinery. Quality control is a critical component of the assembly process; each slicer is thoroughly tested for its cutting efficiency and safety standards before moving on to the finishing phase.

Innovative Technology

As the demands from the food industry evolve, so too does the technology used in meat slicers. The fresh meat slicer factory is at the forefront of innovation, constantly exploring new features that enhance functionality and user experience. Modern meat slicers now come equipped with digital displays, adjustable thickness settings, and self-sharpening blades. These advancements not only improve slicing efficiency but also ensure a consistent cut, which is crucial for presentation and portion control.

fresh meat slicer factory

The trend towards automation has also permeated the realm of meat slicers, with machines designed to minimize manual labor while maximizing output. Automated slicers reduce labor costs and increase productivity, allowing establishments to serve more customers in less time.

Moreover, sustainability is now an integral part of manufacturing processes. Factories are adopting eco-friendly practices, such as utilizing energy-efficient machinery and minimizing waste during production. This commitment to environmentally friendly practices resonates with both consumers and businesses, fostering a more responsible food industry.

Versatility and Applications

Fresh meat slicers are versatile tools that find applications across various sectors. From small butcher shops slicing artisanal cuts of meat to large processing facilities handling bulk orders, these machines are indispensable. They enable users to achieve perfect cuts that enhance product presentation and ensure uniform cooking. Additionally, many factories produce slicers that can handle a variety of foods, including cheese and vegetables, thereby expanding their market reach.

The Future of Fresh Meat Slicers

Looking ahead, the future of fresh meat slicer factories appears bright. The continued evolution of culinary trends will drive demand for innovative slicing solutions. Moreover, as the global food market expands, there will be an increasing need for specialized machinery that can keep pace with the rising standards of food preparation and presentation.

In conclusion, the fresh meat slicer factory plays a crucial role in the food supply chain, providing essential tools that enhance the quality and efficiency of food preparation. With a commitment to precision, innovation, and sustainability, these factories are not only improving the way meat is sliced but are also adapting to meet the evolving needs of the global culinary scene. As the industry continues to advance, one thing is certain fresh meat slicers will remain a vital asset in kitchens around the world, helping chefs and food suppliers deliver exceptional products to their customers.