Sep . 17, 2024 08:42 Back to list

High-Quality China Sausage Casing Tying Machine - Efficient & Reliable

The Evolution of China’s Sausage Casing Tying Machines

In the realm of food processing, the sausage industry has witnessed significant advancements in technology over the years. Among these innovations, China’s sausage casing tying machines stand out as a cornerstone of efficient production in the meat processing sector. With a rich history and increasing global demand for sausages, the design and functionality of these machines have evolved dramatically.

The Evolution of China’s Sausage Casing Tying Machines

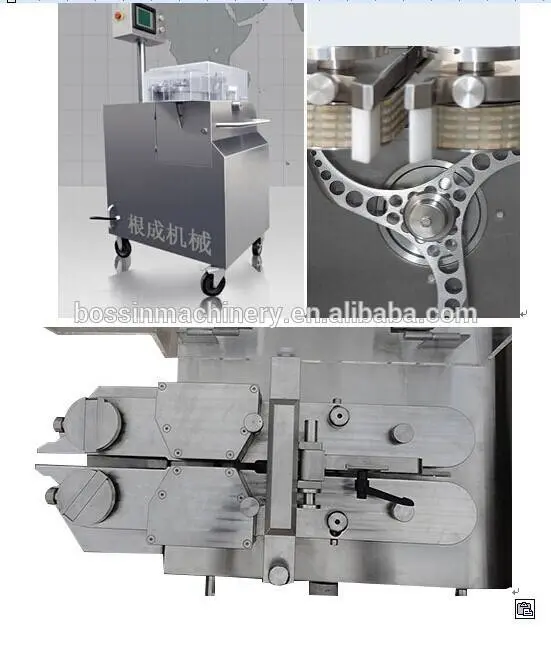

Chinese manufacturers have embraced this technological shift, leveraging advanced engineering and automation to create high-speed tying machines. These machines employ various methods to tie the casings, such as using string, clips, or clips made from metal or plastic. The versatility of these machines allows them to handle different types of casings, ranging from natural to synthetic ones, accommodating various sausage styles and specifications. This adaptability is crucial for manufacturers looking to cater to diverse consumer preferences.

china sausage casing tying machine

Another critical factor driving the popularity of sausage casing tying machines in China is the growing emphasis on food safety and hygiene. Modern machines are designed with easy cleaning and maintenance in mind, complying with international food safety standards. This focus on hygiene not only helps prevent contamination but also extends the shelf life of the products, a major consideration for both manufacturers and consumers.

Moreover, the rise of automation in Chinese factories has led to the incorporation of smart technology into sausage casing tying machines. Features such as programmable settings, touch-screen interfaces, and integration with production management software enhance operational efficiency. Such innovations enable manufacturers to monitor production in real-time and make adjustments to meet specific demands without compromising output quality.

The international market for sausage products is expanding, with consumers becoming increasingly adventurous in their culinary choices. As a result, Chinese sausage casing tying machines are not only catering to domestic markets but are also making significant inroads in overseas markets. Manufacturers are capitalizing on export opportunities, solidifying China's position as a key player in the global meat processing equipment industry.

In conclusion, the evolution of sausage casing tying machines in China reflects a broader trend towards automation and efficiency in food production. As technological innovations continue to reshape the industry, these machines will play an essential role in meeting the needs of a rapidly growing global market, ensuring quality, safety, and consistency in sausage production. With ongoing advancements, the future appears bright for both manufacturers and consumers alike in the world of sausages.

Latest news

-

Pneumatic Clipping Machine- Shijiazhuang Bossin Machinery|Sausage Production Line, Food Processing Machinery

NewsAug.05,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Precision, Efficiency, Durability

NewsAug.05,2025

-

Pneumatic Clipping Machine-Shijiazhuang Bossin Machinery|Precision Sausage Production&Efficient Clipping Technology

NewsAug.05,2025

-

Pneumatic Clipping Machine: Sausage Production Efficiency & Advanced Tech | Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsAug.05,2025

-

Servo Motor Sausage Cutter Spare Parts | Precision Components

NewsAug.05,2025

-

Premounted Side Disc for Efficient Operation - AI-Enhanced

NewsAug.04,2025