jan . 29, 2025 05:47 Back to list

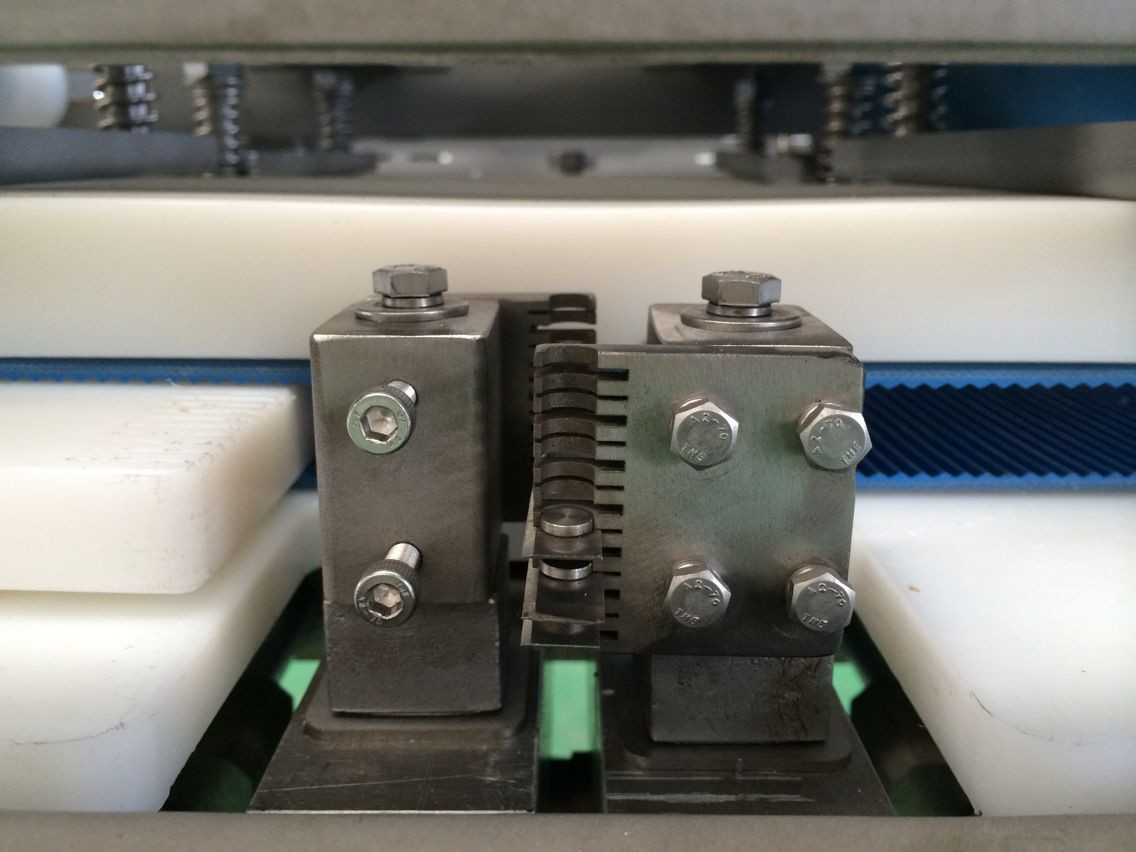

Meat bowl cutter GZB125

High-quality tumbling machines have revolutionized the surface finishing industry, catering to various sectors ranging from automotive parts to delicate jewelry. A product that thrives on its reputation for precision and efficiency, a well-crafted tumbling machine can significantly enhance manufacturing outcomes. By focusing on the four pillars of SEO—Experience, Expertise, Authoritativeness, and Trustworthiness—this article delves into the intricacies of high-quality tumbling machines and their impact across industries.

Trustworthiness comes into play when considering the reliability of high-quality tumbling machines. Due to their robust construction and precision engineering, users can depend on these machines for consistent performance over extended periods. Many manufacturers back their tumbling machines with warranties and customer support services, reinforcing buyer confidence. Testimonials from businesses that have seamlessly integrated these machines into their operations testify to the transformative effects they have had on production lines. The assurance of quality and performance is a testament to the trust these machines inspire within their user base. Moreover, the sustainability aspect of high-quality tumbling machines cannot be overlooked. Many machines are now designed to minimize environmental impact, using consumables that can be recycled or disposed of safely. This focus on eco-friendliness enhances their appeal, aligning with today's green manufacturing standards that many businesses strive to adhere to. High-quality tumbling machines truly encapsulate the synergy between advanced engineering and user-centric design. By delivering unparalleled performance and reliability, they not only enhance the manufacturing process but also uphold the stringent quality standards set by various industries. As businesses continue to seek automation and precision, the role of high-quality tumbling machines in modern production lines becomes increasingly integral. Their ability to deliver consistent quality, reduce costs, and increase throughput makes them an invaluable asset for any production environment. Thus, investing in such technology is synonymous with investing in the future of manufacturing excellence.

Trustworthiness comes into play when considering the reliability of high-quality tumbling machines. Due to their robust construction and precision engineering, users can depend on these machines for consistent performance over extended periods. Many manufacturers back their tumbling machines with warranties and customer support services, reinforcing buyer confidence. Testimonials from businesses that have seamlessly integrated these machines into their operations testify to the transformative effects they have had on production lines. The assurance of quality and performance is a testament to the trust these machines inspire within their user base. Moreover, the sustainability aspect of high-quality tumbling machines cannot be overlooked. Many machines are now designed to minimize environmental impact, using consumables that can be recycled or disposed of safely. This focus on eco-friendliness enhances their appeal, aligning with today's green manufacturing standards that many businesses strive to adhere to. High-quality tumbling machines truly encapsulate the synergy between advanced engineering and user-centric design. By delivering unparalleled performance and reliability, they not only enhance the manufacturing process but also uphold the stringent quality standards set by various industries. As businesses continue to seek automation and precision, the role of high-quality tumbling machines in modern production lines becomes increasingly integral. Their ability to deliver consistent quality, reduce costs, and increase throughput makes them an invaluable asset for any production environment. Thus, investing in such technology is synonymous with investing in the future of manufacturing excellence.

Latest news

-

Pneumatic Clipping Machine: Automated Sausage Production Solution | Shijiazhuang Bossin Machinery Equipment Co., Ltd. | Automated Clipping, Hygienic Design

NewsAug.08,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Automated Clipping

NewsAug.08,2025

-

Fast & Efficient Frozen Meat Block Flaker Machine

NewsAug.08,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery|Sausage Production Efficiency&Hygiene

NewsAug.08,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsAug.07,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|sausage production line,pneumatic technology

NewsAug.07,2025