nov . 19, 2024 21:55 Back to list

rolling machine manufacturers

The Evolution of Rolling Machine Manufacturers Meeting Modern Manufacturing Demands

In the ever-evolving landscape of manufacturing, rolling machines play a crucial role in shaping materials into desired forms. These machines, specifically designed for tasks like bending, shaping, and rolling, are essential in industries ranging from construction to automotive manufacturing. As technology advances and industrial demands increase, rolling machine manufacturers are continually innovating to keep pace with the market's requirements.

History and Development

The inception of rolling machines dates back to the early industrial era, where they were primarily operated manually. The initial designs were straightforward, focusing on basic bending and rolling functions. However, as industries grew and demands for precision and efficiency escalated, manufacturers began to explore advanced designs. The introduction of hydraulic and electronic controls transformed the landscape, allowing for greater precision, repeatability, and efficiency in manufacturing processes.

Today’s rolling machines are equipped with sophisticated features such as CNC (Computer Numerical Control) technology, which allows for more complex and precise operations. This evolution has not only improved the quality of the end products but also greatly enhanced operational efficiency, thus reducing manufacturing lead times and costs.

Key Features of Modern Rolling Machines

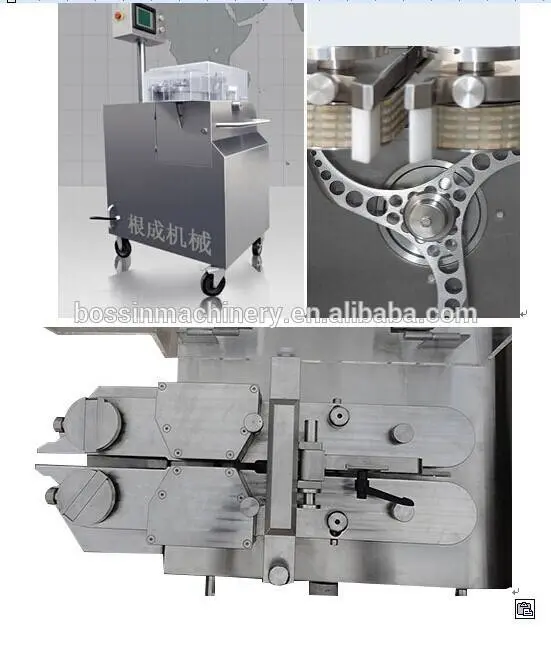

Modern rolling machines possess several remarkable attributes that distinguish them from their predecessors. One of the most significant advancements is the integration of automation and software. These machines can now be programmed to execute a series of operations with minimal human intervention. Features such as automated tool changing and interconnected systems for inventory management further streamline the manufacturing process.

Furthermore, today’s rolling machines often come with enhanced safety features. The development of safety guards, emergency stop functions, and operator training programs ensures a safer working environment. Manufacturers are increasingly focusing on ergonomics as well, designing machines that not only produce high-quality results but also ensure operator comfort.

rolling machine manufacturers

Industry Applications

Rolling machines are versatile and find applications across numerous sectors. In the construction industry, they are essential for producing metal components like beams, columns, and frames. Similarly, the automotive industry utilizes these machines to fabricate parts such as body panels, and chassis components. Moreover, the energy sector, particularly in wind and renewable energy, relies on rolling machines to create large-scale components like pipe structures and turbine blades.

As industries increasingly shift towards sustainability, the demand for eco-friendly manufacturing practices has risen. Rolling machine manufacturers are responding by developing machines that consume less energy and generate less waste. This shift not only aligns with global sustainability goals but also offers manufacturers a competitive edge by lowering operational costs.

Future Trends in Rolling Machine Manufacturing

Looking forward, the future of rolling machine manufacturing appears promising. Industry 4.0, the fourth industrial revolution, is significantly impacting the way manufacturing processes operate. The implementation of IoT (Internet of Things) technologies in rolling machines is becoming more prevalent, enabling real-time monitoring and predictive maintenance. This connectivity allows manufacturers to optimize machine performance, thus enhancing productivity and reducing downtime.

Moreover, advancements in materials science are leading to the production of rolling machines that can handle a wider range of materials, including composites and high-strength alloys. This adaptability will facilitate the manufacturing of innovative products that cater to emerging markets and technologies.

Conclusion

In conclusion, rolling machine manufacturers are at the forefront of an increasingly sophisticated and dynamic manufacturing environment. Through continued innovation, they are not only enhancing operational efficiency and productivity but also contributing to a more sustainable future. As the demands of various industries evolve, rolling machine manufacturers are poised to meet these challenges, ensuring they remain vital players in the global manufacturing landscape. Their ability to adapt and innovate will ultimately dictate their success and influence in the realms of modern manufacturing.