nóv . 09, 2024 03:52 Back to list

Chicken Separation Solutions for Efficient Processing and Sourcing Suppliers

The Importance of Choosing the Right Chicken Separating Supplier

In the poultry industry, efficiency and quality are paramount. One crucial aspect of poultry processing is the separation of chicken parts—the wings, thighs, breasts, and other components from each bird. This process not only enhances the quality of the products but also optimizes production efficiency. As businesses strive to meet consumer demands, selecting the right chicken separating supplier becomes a vital decision. In this article, we will explore the key factors to consider when choosing a chicken separating supplier and the benefits of making an informed choice.

Understanding Chicken Separation

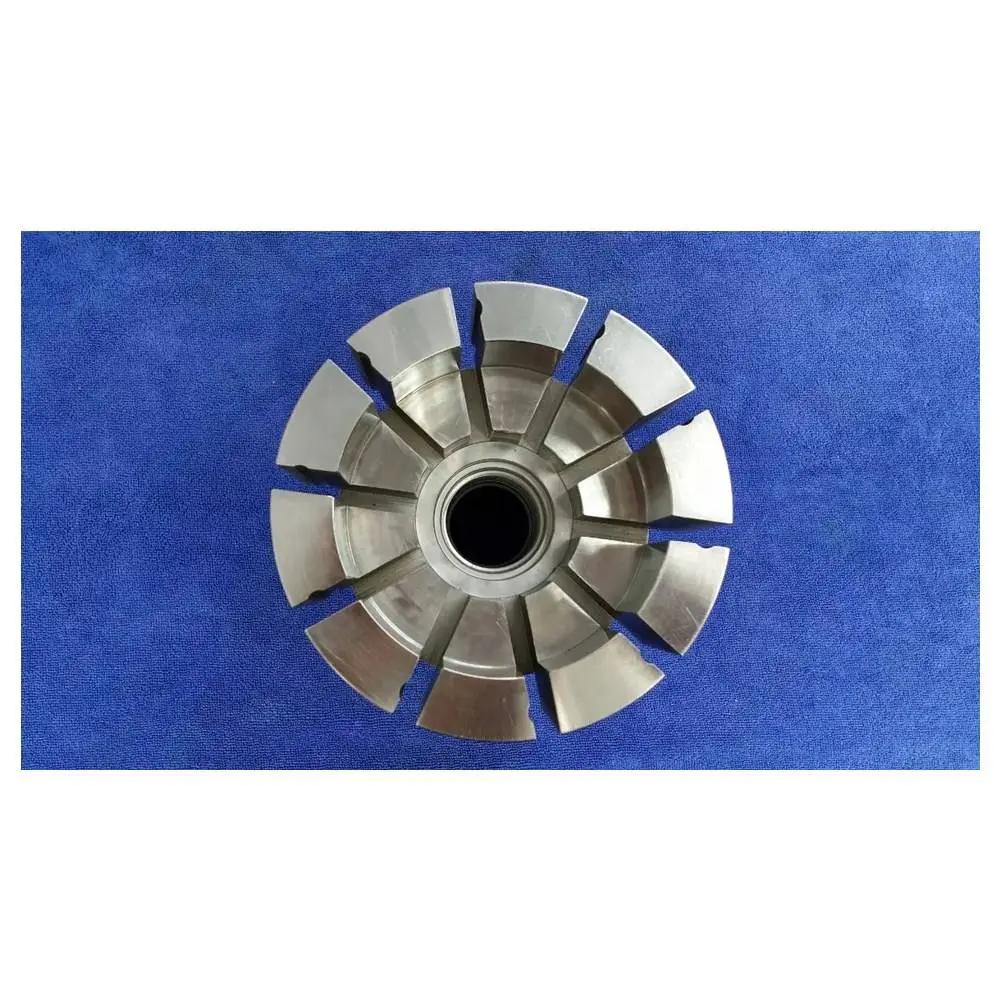

Chicken separation involves various techniques and machinery designed to break down whole chickens into various parts while maintaining the integrity of the meat. Automated separating equipment is widely used in modern processing plants, significantly increasing productivity compared to manual methods. A reliable chicken separating supplier will provide advanced technology and machines that ensure efficient operations, reduced waste, and improved safety standards.

Factors to Consider When Choosing a Supplier

1. Quality of Equipment The first consideration should be the quality of the machinery. A reputable supplier will provide robust, durable equipment that meets industry standards. Look for suppliers that offer well-maintained, innovative machines that can handle the volume of production your business requires. Additionally, check for certifications that indicate compliance with safety and quality regulations.

2. Technology and Innovation The poultry industry is constantly evolving, with advancements in technology improving efficiency and product quality. Suppliers that invest in the latest technology, such as automated separating systems and AI-driven machines, can help your business stay competitive in a fast-paced market. Investigating a supplier’s commitment to research and development can provide insights into their innovative capabilities.

3. Customization Options Every processing plant has unique requirements based on its size, production volume, and specific needs. A good supplier should offer customizable solutions that cater to these unique conditions. Discuss your requirements with potential suppliers to understand how they can adapt their equipment and services to suit your business.

4. Customer Support and Training After purchasing equipment, the supplier’s support becomes crucial. Look for suppliers that offer comprehensive training programs for your staff, ensuring they can operate the machinery safely and effectively. Moreover, a responsive customer support team is essential for addressing any issues or breakdowns that may occur.

5. Reputation and Experience Research the supplier's reputation in the industry. Customer reviews, testimonials, and case studies can provide valuable insights into their performance and reliability. Suppliers with extensive experience in the field are likely to understand the complexities of poultry processing and can offer practical solutions to common challenges.

chicken separatinjg supplier

6. Cost-Effectiveness While the initial cost of equipment is an important factor, long-term value should be the primary focus. Assessing the total cost of ownership, including maintenance, energy consumption, and potential downtime, can help you make a more informed decision. Compare quotes from multiple suppliers to ensure you are getting a competitive price without sacrificing quality.

Benefits of Choosing the Right Chicken Separating Supplier

Selecting the right chicken separating supplier can significantly impact your processing business

. Here are several key benefits- Increased Efficiency Advanced machinery allows for faster processing times, enabling your plant to operate at optimal capacity.

- Quality Assurance High-quality separating machines preserve the integrity of chicken parts, improving product quality and reducing spoilage.

- Reduced Labor Costs Automation minimizes the need for manual labor, leading to lower labor costs and a reduction in workplace injuries.

- Scalability Reliable suppliers can provide solutions that allow for easy scaling of operations as your business grows, ensuring your equipment remains effective as demand increases.

- Enhanced Reputation Consistently high-quality products will enhance your brand's reputation in the market, leading to increased sales and customer loyalty.

Conclusion

The choice of a chicken separating supplier is a critical decision that can influence your business's overall success. By considering factors such as equipment quality, technology, customization, customer support, reputation, and cost-effectiveness, poultry processors can find a partner that aligns with their needs and goals. Making an informed choice will not only streamline operations but also ensure the delivery of high-quality products that meet consumer expectations. Investing time in selecting the right supplier is essential in today’s competitive market.