des . 16, 2024 19:20 Back to list

Meat Processing Elevator Solutions for Efficient Material Handling in Manufacturing

Meat Bin Elevator Manufacturers Enhancing Efficiency in Food Processing

In the food processing industry, particularly in meat processing facilities, the efficiency and safety of operations are paramount. One of the key components that contribute to these objectives is the meat bin elevator. This innovation has become essential in modern meat processing plants, where high volumes of product must be handled with precision and care. This article explores the significance of meat bin elevators, the manufacturers behind them, and their contributions to the industry.

The Importance of Meat Bin Elevators

Meat bin elevators serve a crucial role in the transportation of heavy and bulky meat bins from one level of a processing plant to another. These elevators facilitate the movement of raw materials, semi-processed products, and finished goods while minimizing the risk of contamination and ensuring compliance with food safety standards. By automating the transport of meat bins, producers can greatly reduce manual handling, which not only increases efficiency but also improves workplace safety by reducing the potential for injuries among workers.

Moreover, meat bin elevators can be designed to accommodate various sizes and types of bins, ensuring versatility in operations. This adaptability enables processing plants to optimize their layout and workflow, which is particularly important in environments where space is at a premium.

Choosing the Right Manufacturer

When selecting a meat bin elevator manufacturer, several factors should be considered to ensure the best fit for a specific facility's needs

. First and foremost is the manufacturer's experience in the food processing industry. A manufacturer with a strong track record in producing equipment tailored for meat processing will have an in-depth understanding of the industry’s stringent requirements for hygiene and safety.Additionally, prospective buyers should assess the customization options available from the manufacturer. Many facilities have unique operational needs that may require tailored solutions. A good manufacturer will offer the flexibility to design and build elevators that fit specific workflows and processing requirements.

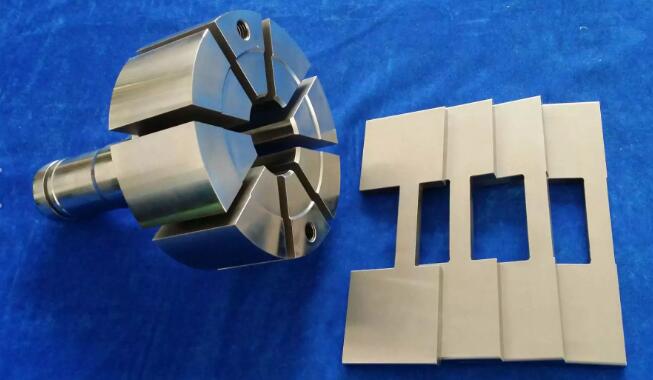

meat bin elevator manufacturer

Another crucial aspect is the durability and reliability of the elevator. Given the heavy usage and the stress that equipment undergoes in busy processing plants, it is essential to choose a manufacturer known for producing robust and long-lasting products. Investing in high-quality equipment can significantly reduce maintenance costs and downtime over time.

Industry Standards and Compliance

A reputable meat bin elevator manufacturer should adhere to industry standards and regulations related to food safety and equipment design. Manufacturers must ensure that their products meet compliance requirements, including the guidelines put forth by the Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA). Elevators should be designed for easy cleaning and maintenance to prevent bacterial growth and cross-contamination, which is critical in meat processing.

Innovations in Meat Bin Elevator Design

As technology advances, so do the capabilities of meat bin elevators. Modern manufacturers are incorporating features such as automated loading and unloading systems, enhanced safety mechanisms, and energy-efficient designs. These innovations not only streamline operations but also reduce the environmental footprint of meat processing facilities.

Furthermore, the integration of Internet of Things (IoT) technologies is revolutionizing how meat bin elevators are monitored and managed. Facilities can now track the performance of their equipment in real-time, allowing for proactive maintenance and reduced chances of breakdowns. This technology not only aids in efficiency but also contributes to overall operational transparency.

Conclusion

In conclusion, meat bin elevators play a vital role in the meat processing industry by enhancing operational efficiency, ensuring safety, and maintaining compliance with food safety standards. As manufacturers continue to innovate and improve the design and functionality of these elevators, processing facilities can expect significant advancements in productivity and cost-effectiveness. Ultimately, the right meat bin elevator manufacturer will be an invaluable partner in optimizing meat processing operations, allowing businesses to meet growing consumer demands while upholding the highest standards of quality and safety. As the industry continues to evolve, keeping an eye on emerging technologies and trends in meat bin elevator manufacturing will be crucial for success.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025