des . 20, 2024 15:06 Back to list

Vacuum Tumbling Machines for Meat Production from Leading Manufacturers

Understanding Vacuum Meat Tumbling Machine Factories Innovations and Importance in Food Processing

In the realm of food processing, vacuum meat tumbling machines have emerged as essential tools in enhancing meat quality, flavor, and tenderness. The capabilities of these machines not only streamline the manufacturing process but also ensure that the final product meets high standards of taste and texture. As the demand for various meat products continues to rise, so does the importance of vacuum meat tumbling machine factories.

What is a Vacuum Meat Tumbling Machine?

A vacuum meat tumbling machine is specifically designed to marinate and tenderize meat products by using a combination of vacuum technology and mechanical agitation. The machine operates by placing meat along with brine or marinade into a sealed drum, where a vacuum is applied. This vacuum causes the meat fibers to expand, allowing the marinade to penetrate more deeply. The continuous tumbling action further aids in the uniform distribution of the marinade and promotes even seasoning throughout the meat.

Advantages of Vacuum Tumbling Technology

1. Enhanced Flavor and Juiciness One of the primary benefits of using a vacuum tumbler is the significant enhancement of flavor. By allowing the marinade to penetrate deeply, the meat retains moisture better during cooking, leading to juicier and more flavorful products.

2. Improved Tenderness The mechanical action of tumbling not only helps to infuse flavors but also breaks down muscle fibers, resulting in a tender texture. This is crucial for meat products like chicken breasts, pork loins, and beef cuts, which consumers prefer to be tender and easy to chew.

3. Time Efficiency Traditional marination processes can take hours, if not days. Vacuum tumbling machines drastically reduce this time, allowing manufacturers to produce higher volumes of meat products in shorter periods. This efficiency translates to better productivity and profitability for factories.

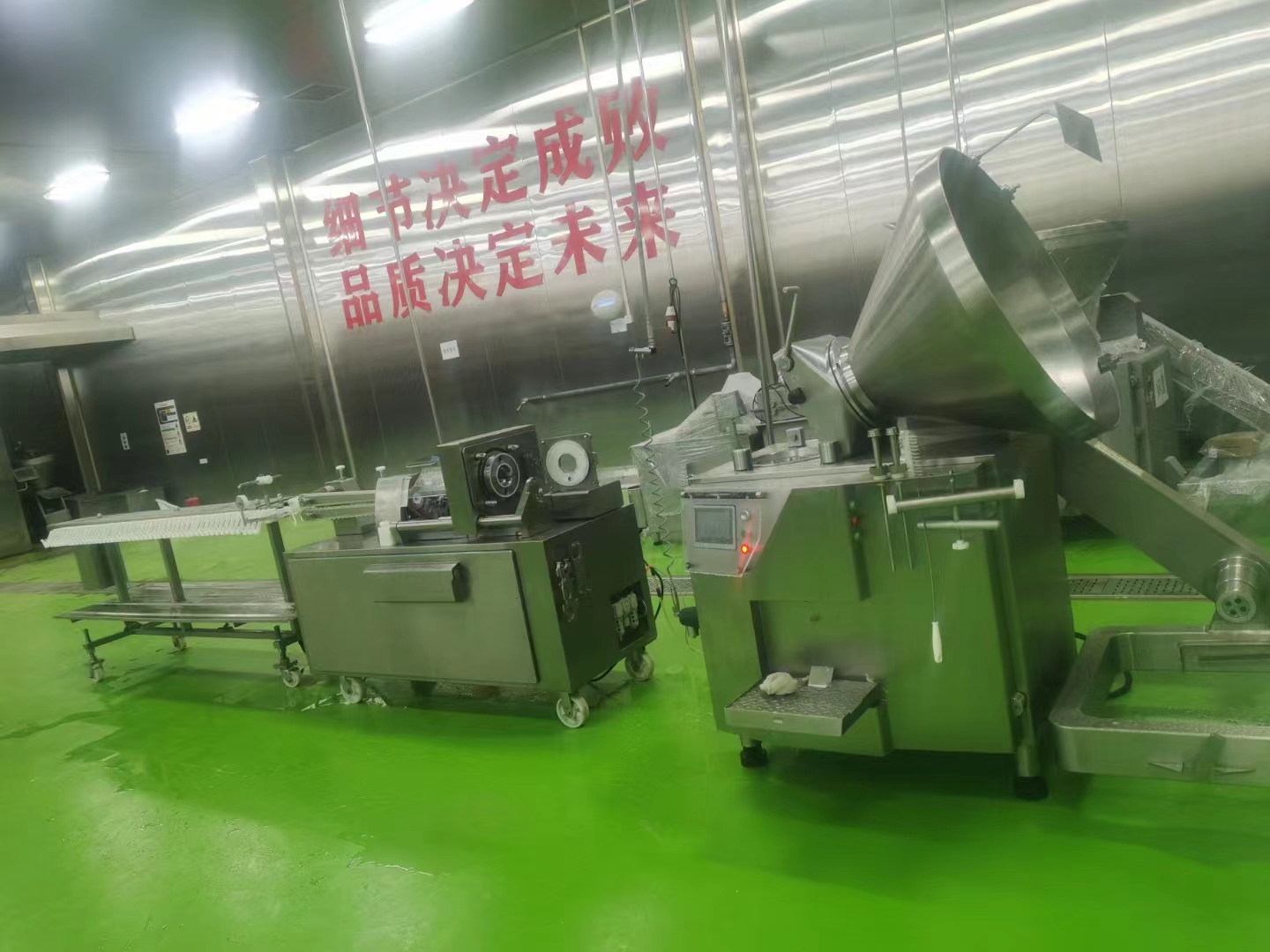

vacuum meat tumbling machine factories

4. Consistency in Production Maintaining quality across batches is essential in the food industry. Vacuum tumbling machines provide uniform results, ensuring that every piece of meat receives the same treatment, yielding consistent taste and texture.

The Role of Factories in Innovation

The factories that specialize in the production of vacuum meat tumbling machines play a crucial role in the advancement of food processing technology. These factories invest in research and development to improve existing designs and to create new solutions that cater to the evolving needs of the meat processing industry.

1. Customization Different types of meats require different tumbling processes. Leading factories offer customizable solutions, enabling clients to tailor machines to their specific meat processing needs, whether it’s for larger operations or more niche products.

2. Integration of Smart Technology Many modern vacuum tumbling machine factories are integrating smart technology into their designs. This includes features like digital control systems, which allow for precise monitoring of time, temperature, and vacuum levels. Such innovations enhance process control and ensure optimal results.

3. Sustainability Practices As sustainability becomes a priority in the food industry, vacuum tumbling machine factories are exploring eco-friendly practices. This includes the development of machines that use less energy and water, thereby reducing the environmental impact of meat processing.

Conclusion

In conclusion, vacuum meat tumbling machine factories are not just manufacturers of equipment; they are pivotal in shaping the future of the meat processing industry. With their focus on quality, efficiency, and technological advancements, these factories contribute significantly to producing better meat products that meet consumer demands. As the industry continues to evolve, the collaboration between meat processors and machine manufacturers will likely lead to even more innovative solutions, ensuring that meat products are not only safe and nutritious but also full of flavor and texture that consumers desire. The significance of these factories cannot be overstated, as they help bridge the gap between traditional meat processing methods and modern culinary expectations.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025