Gen . 26, 2025 05:55 Back to list

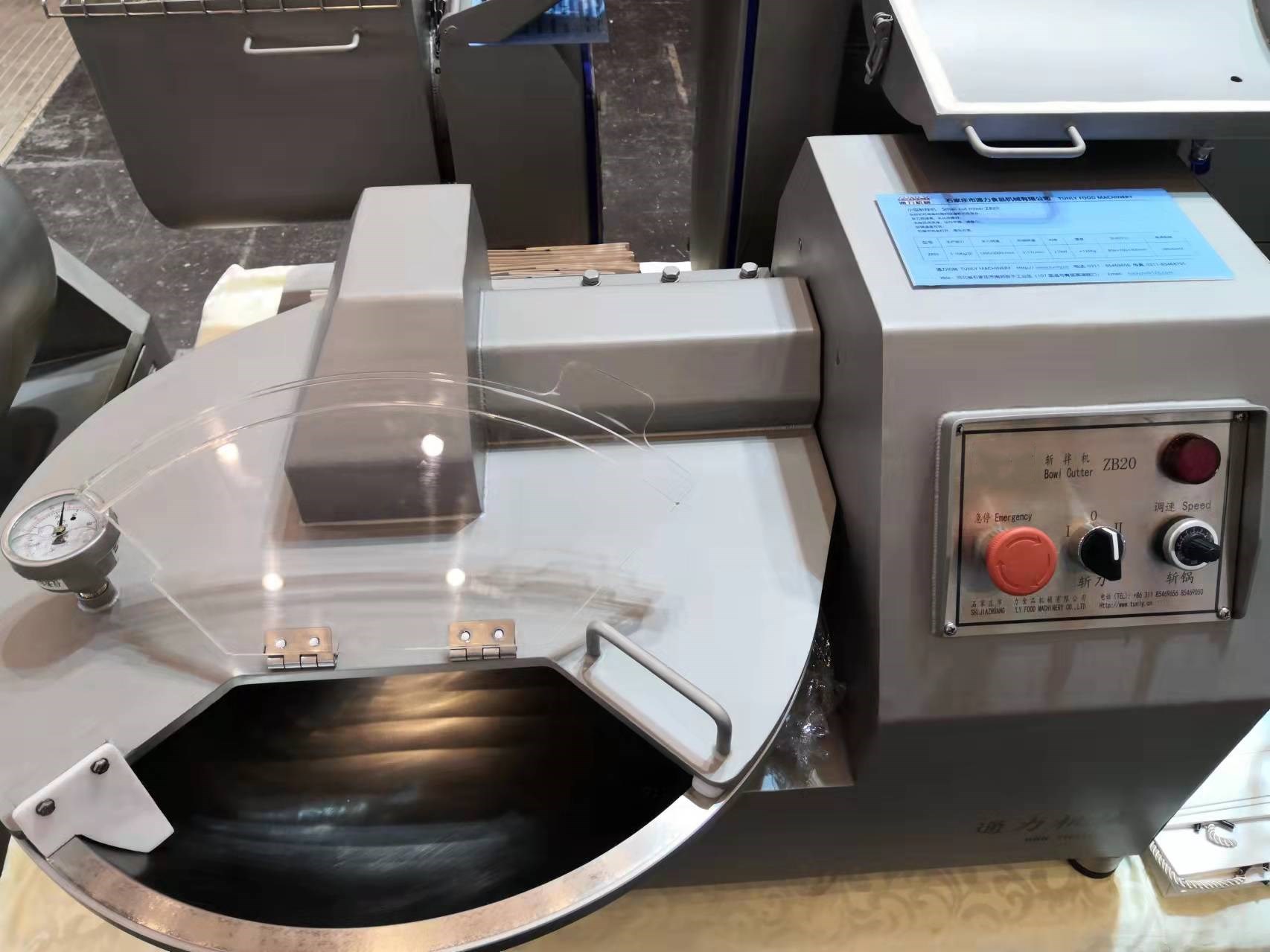

bowl cutter machine meat

For those in the meat processing industry, the bowl cutter machine represents a critical component in achieving the desired texture and blend for various meat products. Its ability to finely chop, emulsify, and mix meat efficiently positions it as an indispensable tool for any professional kitchen or meat processing facility.

From a trustworthiness perspective, the decision to incorporate a bowl cutter machine into your production line should also factor in user reviews and testimonials. Operators often share insights into which models have proven most reliable over time, which can be crucial for minimizing downtime and maximizing productivity. Furthermore, the ease of maintenance and availability of replacement parts are critical aspects that determine long-term satisfaction with the machine. In practical terms, using a bowl cutter machine effectively involves several key steps, starting with the preparation of the meat. Ensuring the meat is chilled before processing not only aids in achieving the desired texture but also contributes to food safety by reducing bacterial growth. Once the meat is adequately prepared, it's loaded into the machine, where precise control over the cutting process can be maintained through various settings. The versatility of the bowl cutter machine allows for not just meat processing but also the integration of spices and other ingredients, achieving a homogenous mix ideal for premium products. In conclusion, the bowl cutter machine stands as a vital component of any meat processing operation. Its efficient design and customizable features cater to a range of applications, enhancing both the quality and consistency of meat products. When selected and operated with care and professionalism, it guarantees excellence, ensuring your products stand out in a competitive marketplace. Investing in a reliable and well-maintained bowl cutter machine is not just a choice; it's a testament to a commitment to quality and efficiency in meat processing.

From a trustworthiness perspective, the decision to incorporate a bowl cutter machine into your production line should also factor in user reviews and testimonials. Operators often share insights into which models have proven most reliable over time, which can be crucial for minimizing downtime and maximizing productivity. Furthermore, the ease of maintenance and availability of replacement parts are critical aspects that determine long-term satisfaction with the machine. In practical terms, using a bowl cutter machine effectively involves several key steps, starting with the preparation of the meat. Ensuring the meat is chilled before processing not only aids in achieving the desired texture but also contributes to food safety by reducing bacterial growth. Once the meat is adequately prepared, it's loaded into the machine, where precise control over the cutting process can be maintained through various settings. The versatility of the bowl cutter machine allows for not just meat processing but also the integration of spices and other ingredients, achieving a homogenous mix ideal for premium products. In conclusion, the bowl cutter machine stands as a vital component of any meat processing operation. Its efficient design and customizable features cater to a range of applications, enhancing both the quality and consistency of meat products. When selected and operated with care and professionalism, it guarantees excellence, ensuring your products stand out in a competitive marketplace. Investing in a reliable and well-maintained bowl cutter machine is not just a choice; it's a testament to a commitment to quality and efficiency in meat processing.

Latest news

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Automated Meat Processing

NewsAug.08,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd. | Sausage Production Line, Precision Clipping

NewsAug.08,2025

-

Pneumatic Clipping Machine: Automated Sausage Production Solution | Shijiazhuang Bossin Machinery Equipment Co., Ltd. | Automated Clipping, Hygienic Design

NewsAug.08,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Sausage Production Line, Automated Clipping

NewsAug.08,2025

-

Fast & Efficient Frozen Meat Block Flaker Machine

NewsAug.08,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery|Sausage Production Efficiency&Hygiene

NewsAug.08,2025