11月 . 09, 2024 12:15 Back to list

Sausage Processing Techniques for Efficient Smokehouse Operations and Flavor Enhancement

The Role of Smokehouses in Sausage Processing

Smokehouses are integral to the art of sausage processing, combining both functionality and tradition to create flavorful, preservative-rich products. From the ancient practices of smoke curing to modern advancements in food processing technology, smokehouses have evolved significantly over the years. However, the essence of using smoke to enhance flavor and preserve meats remains unchanged.

Historical Context

The tradition of smoking meats dates back thousands of years, likely originating in various cultures that discovered the dual benefits of smoke as a preservative and flavor enhancer. Before the advent of refrigeration, smoking was a critical method for extending the shelf life of meats and fish. Smokehouses were simple structures built from wood and stone, designed to allow smoke from smoldering wood to permeate the meat. The low temperatures and the anti-bacterial properties in the smoke prevented spoilage, making this method crucial for survival.

Types of Smokehouses

There are primarily two types of smokehouses used in sausage processing traditional and commercial. Traditional smokehouses, often found in small-scale operations, utilize wood or charcoal as their main fuel source. These smokehouses can be quite rudimentary, focusing on artisan production methods that emphasize quality over quantity. The result is often a uniquely flavored product, with variations based on the type of wood used—as different woods impart different flavors to the meat.

On the other hand, commercial smokehouses are technologically advanced, allowing for more precision and efficiency. These systems can control temperature and humidity, which are critical factors in the smoking process. They can include features such as digital controls, automated smoke generation, and advanced airflow systems. This results in consistent high-quality product output, which is essential for large-scale sausage production. Yet, even in commercial setups, many producers still prioritize traditional methods to maintain authenticity and flavor.

The Smoking Process

The smoking process in sausage production involves several steps that can vary depending on the desired outcome. Generally, the meat is first blended with spices and then stuffed into casings—often made from hog or sheep intestine. Once the sausages are prepared, they are placed in the smokehouse. The smoking process begins with the heat source, which can be direct or indirect, often derived from wood, charcoal, or gas.

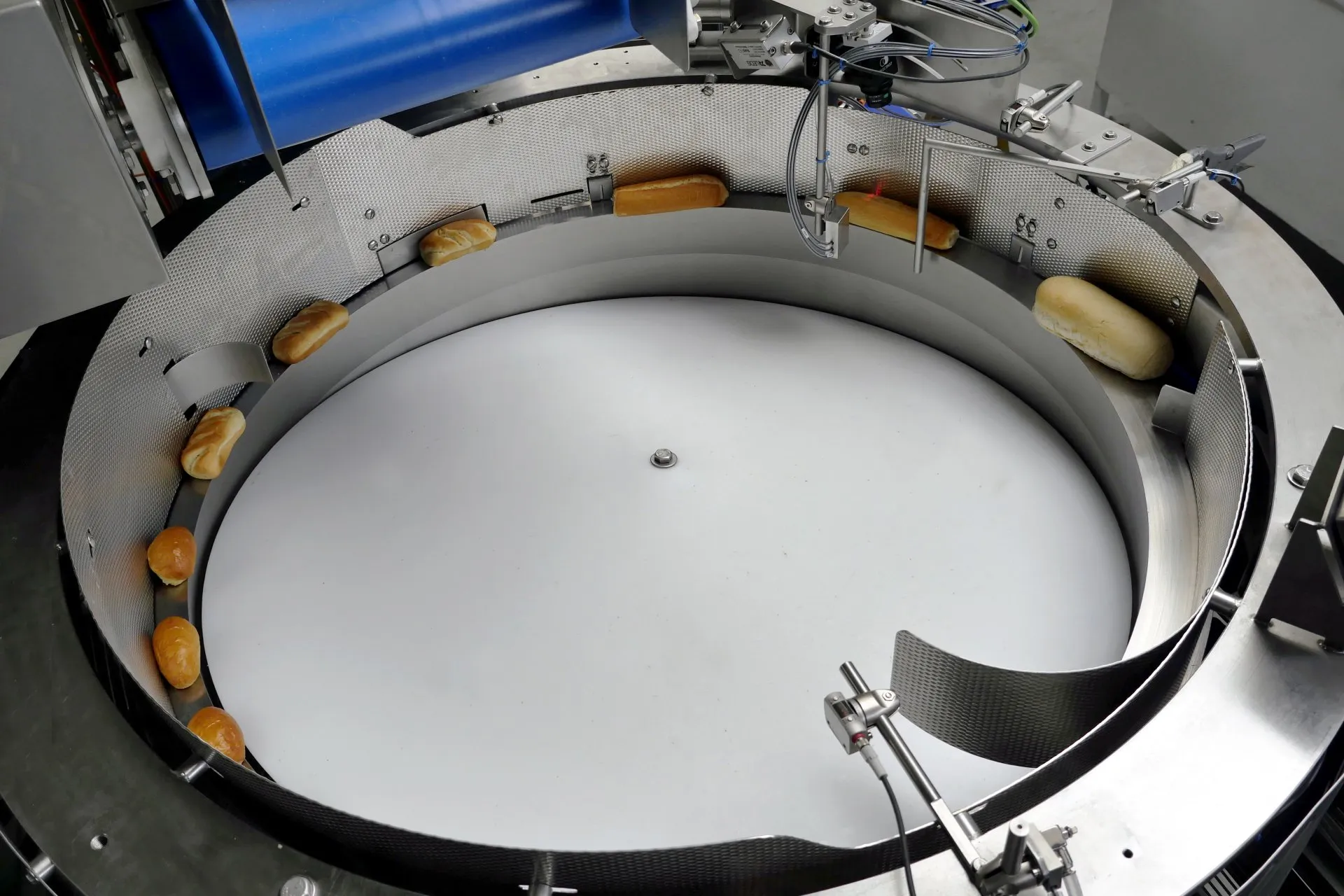

smoke house for sausage processing

Temperature control is vital during smoking. Typically, the smoking temperatures range from 140°F to 180°F (60°C to 82°C). This range allows the meat to cook slowly while absorbing the smoke flavor. During this process, the proteins in the meat undergo several chemical transformations. The smoke reacts with the surface of the meat, creating a flavorful crust while also aiding in preservation.

Flavor Development

One of the primary benefits of using a smokehouse for sausage processing is the development of complex flavors. The chemical compounds in smoke contribute to a distinctive taste and aroma, often described as savory, sweet, or even spicy, depending on the type of wood used. Popular choices include hickory, mesquite, apple, and cherry, each imparting a unique signature to the final product.

Moreover, the smoking process can also introduce a certain level of sweetness and depth due to the Maillard reaction, which occurs when proteins and sugars react under heat. This complexity in flavor is highly coveted among sausage lovers and is a driving force behind artisanal production methods.

Health and Safety Considerations

While smoking is an effective preservation method, it is essential to adhere to safety standards during the sausage-making process. Proper temperature control is crucial, as inadequate smoking can lead to foodborne illnesses. Additionally, it is important to select high-quality wood that is free from chemicals and toxins, which could compromise the safety and flavor of the sausages.

Conclusion

In conclusion, smokehouses play a vital role in sausage processing, bridging tradition and technology to produce flavorful and safe meat products. Whether through the time-honored methods of small artisans or the efficiency of commercial operations, the act of smoking enhances not only the taste but also the longevity of sausages. As consumers increasingly seek authentic and high-quality food experiences, the importance of smokehouses in sausage production is more relevant than ever. As we look to the future, the continued appreciation for this ancient technique will surely inspire new generations of sausage makers to embrace and innovate upon these traditional practices.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025