ធ្នូ . 11, 2024 10:37 Back to list

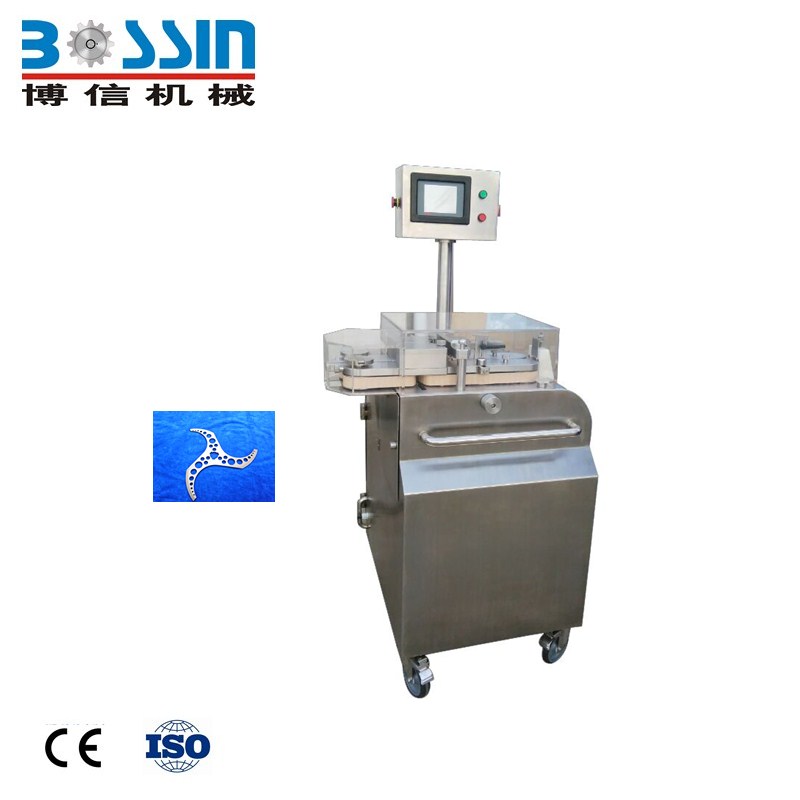

Leading Manufacturer of Automatic Meat Brine Injection Equipment for Optimal Flavor Enhancement

The Rise of Automatic Meat Brine Injector Manufacturers

In the ever-evolving landscape of the food processing industry, the demand for automation and efficiency has led to significant advancements in meat preparation technology. Among these, automatic meat brine injectors have emerged as a game-changer, allowing processors to enhance flavor and tenderness in meat products while improving productivity. As the market for these innovative machines continues to expand, several manufacturers are leading the charge in providing high-quality solutions tailored to meet diverse operational needs.

Understanding Meat Brining

Brining is a traditional method that involves soaking meat in a saltwater solution, often enhanced with spices and other flavorings. This process not only enhances the meat's flavor but also improves its moisture retention during cooking, resulting in a juicier final product. However, traditional brining methods can be labor-intensive and inconsistent. Enter the automatic meat brine injector - a sophisticated device designed to inject brine directly into the meat, ensuring uniform distribution and flavor absorption.

Benefits of Automatic Brine Injectors

The transition from manual to automatic brine injectors brings several distinct advantages

1. Increased Efficiency Automatic systems can inject brine at a much faster rate than manual methods, significantly reducing processing time. This efficiency enables meat processors to meet high demand without compromising quality.

2. Precision Modern automatic brine injectors utilize advanced technology to ensure precise control over the injection process. This precision allows for consistent flavor and salt levels in each piece of meat, helping manufacturers maintain quality across batches.

3. Labor Reduction By automating the brining process, manufacturers can reduce the reliance on manual labor, addressing labor shortages and helping to lower operational costs.

4. Enhanced Product Quality The ability to inject brine evenly throughout the meat results in products that are more flavorful and tender. This quality enhancement can lead to increased customer satisfaction and loyalty.

automatic meat brine injector manufacturer

5. Customization Many automatic brine injector systems offer customizable settings, allowing manufacturers to experiment with different brine formulations and injection patterns. This flexibility supports product innovation and differentiation in a competitive market.

Leading Manufacturers in the Industry

As demand for automatic meat brine injectors grows, several manufacturers have established themselves as key players in the field. Here are a few notable companies

- Marel Known for its cutting-edge technology, Marel manufactures a range of injection solutions tailored for various types of meat products. Their systems are designed for both large-scale processors and smaller operations, showcasing adaptability across the industry.

- Handtmann With a strong focus on innovation, Handtmann provides automatic brine injectors that combine reliability with usability. Their equipment is designed for easy integration into existing production lines, minimizing downtime during installation.

- Talsa This manufacturer specializes in creating robust and efficient brining machines that cater to different meat sizes and types. Talsa's products are recognized for their durability and ease of maintenance, making them a favorite among processors.

- LASKA An established name in the food processing industry, LASKA offers high-performance brine injectors that emphasize user-friendly operation. Their machines are designed for maximum efficiency without sacrificing product quality.

The Future of Meat Brine Injectors

As the food industry continuously embraces automation, the future of meat brine injectors looks promising. Innovations in technology, such as IoT connectivity and machine learning algorithms, are set to further enhance the capabilities of these machines. Manufacturers are likely to invest in research and development to create smarter machines that optimize brining processes, track performance in real-time, and predict maintenance needs.

In conclusion, automatic meat brine injectors are revolutionizing the way meat is processed by enhancing flavor, improving texture, and increasing efficiency. With several leading manufacturers driving innovation, the industry is poised for continued growth. As food safety and quality standards become increasingly stringent, these machines will play an essential role in providing processors with the means to meet consumer expectations while maintaining competitive advantages in the marketplace. As technology progresses, the future of meat brining will be characterized by even more sophisticated solutions, helping processors deliver consistently high-quality products to their customers.

Latest news

-

Great Wall DKJC Series Auto Sausage Clipper: Efficient & Durable

NewsJul.25,2025

-

Pneumatic Clipping Machine: Efficient and Reliable Solution for Industrial Applications|Precision Cutting, Durability

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsJul.21,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Precision Cutting, High-Speed Operations

NewsJul.21,2025