កញ្ញា . 21, 2024 14:57 Back to list

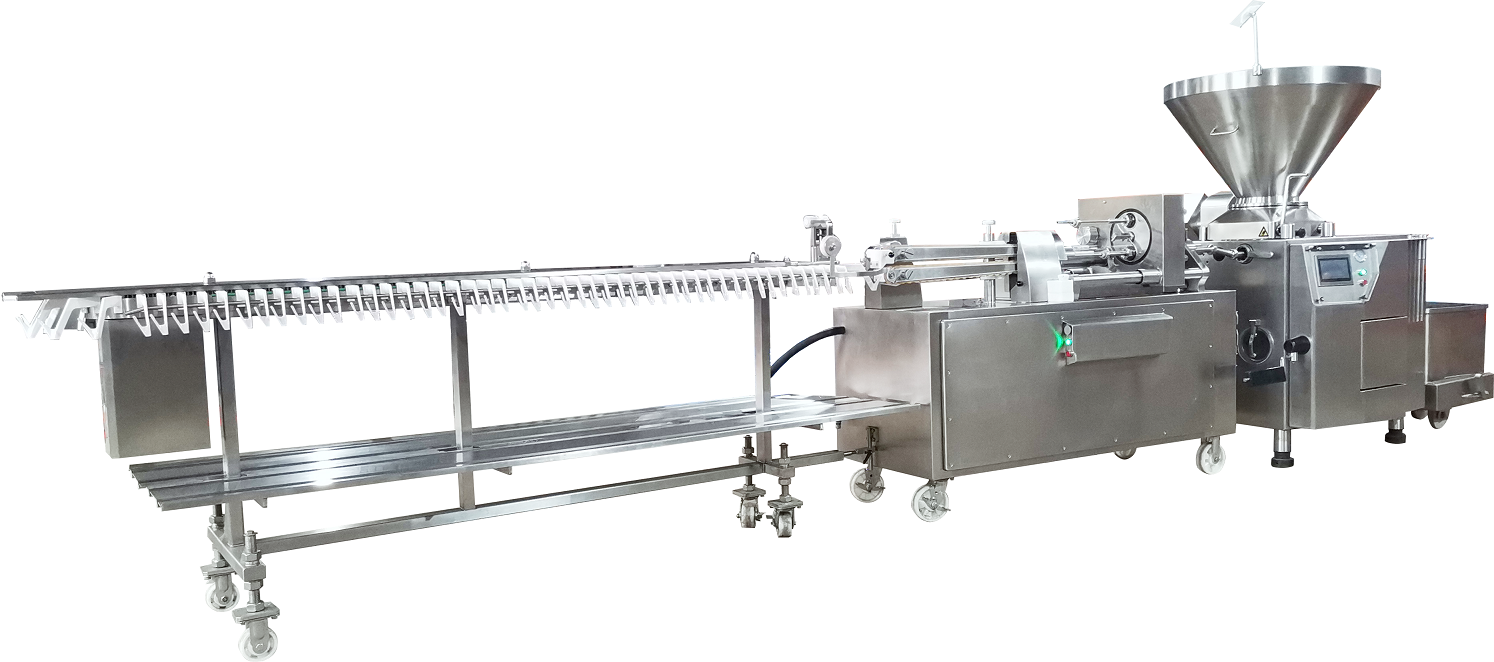

burger meat patty forming machine factory

The Evolution of Burger Meat Patty Forming Machines

In the ever-evolving landscape of the food industry, efficiency and quality are paramount, especially when it comes to producing beloved items like burgers. The burger meat patty forming machine has emerged as a revolutionary tool, transforming how patties are created in factories around the world. This innovation not only streamlines the process but also ensures consistency and quality that consumers have come to expect.

Burger joints and food factories are pressured to meet increasing demands without compromising on quality. Hand-forming patties, while traditional, is labor-intensive and can lead to inconsistencies in size and thickness. This is where the burger meat patty forming machine comes into play. By automating the patty formation process, these machines significantly reduce human error, ensuring that each patty is uniform in shape and weight.

The technology behind these machines has advanced significantly in recent years. Modern burger meat patty forming machines are equipped with precision engineering, allowing for adjustable thickness and size settings. This flexibility enables producers to cater to different market demands, whether it's a classic quarter-pounder or a thinner slider. Additionally, many machines are designed to handle various types of meat, including beef, turkey, chicken, and plant-based alternatives, reflecting the growing trend toward diverse dietary options.

Another major advantage of using a forming machine is the speed at which patties can be produced. A skilled worker may take several minutes to form a single patty, while a machine can produce dozens in the same timeframe. This efficiency not only enhances productivity but also reduces labor costs, allowing companies to allocate resources to other critical areas of the business.

burger meat patty forming machine factory

Moreover, there’s a strong emphasis on food safety and hygiene in the production process. Modern forming machines are designed with materials that are easy to clean and sanitize, helping to minimize the risk of contamination. This aspect is increasingly important in today’s health-conscious market, where consumers are more aware of food safety standards.

Energy efficiency is another consideration with these machines. Many manufacturers have started producing models that consume less energy while providing optimal performance. This is not only beneficial for the operating costs of food producers but also aligns with global sustainability goals, making the burger production process more environmentally friendly.

Looking to the future, the burger meat patty forming machine will likely continue to evolve with advancements in technology. Features like smart connectivity may allow for real-time monitoring of production lines, optimizing efficiency, and quality control. Additionally, as plant-based meats gain popularity, new innovations in forming technology will be crucial to accommodate these products.

In conclusion, the burger meat patty forming machine exemplifies how technology can enhance production processes in the food industry. By providing efficiency, consistency, and adaptability, these machines have become invaluable in meeting consumer demands. As the market continues to evolve, the role of innovative machinery like the patty forming machine will only expand, paving the way for a more efficient, diverse, and quality-driven food industry.