វិច្ឆិកា . 01, 2024 13:29 Back to list

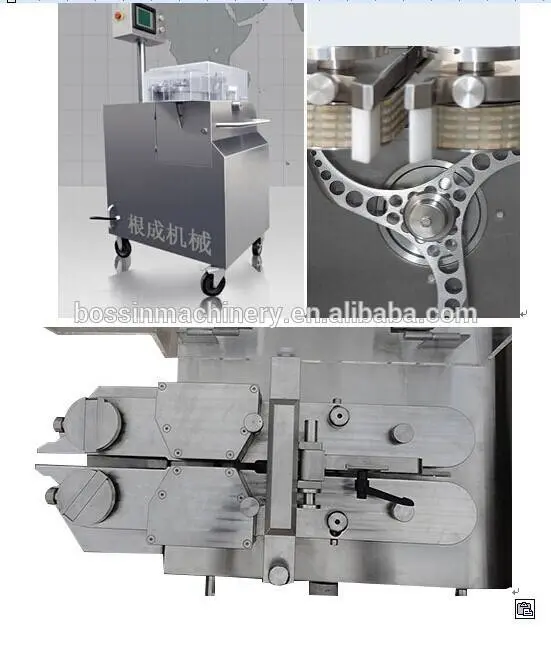

Vacuum Filler Rotor Manufacturers and Their Product Offerings for Efficient Production

The Importance of Quality Rotor for Vacuum Fillers A Guide for Suppliers

In the world of food and beverage manufacturing, the efficiency and effectiveness of production processes are paramount. One crucial component often overlooked is the rotor used in vacuum fillers. This device plays a significant role in ensuring that products are filled accurately and consistently, making it a focal point for suppliers looking to maintain high standards in their offerings.

The Importance of Quality Rotor for Vacuum Fillers A Guide for Suppliers

When sourcing rotors for vacuum fillers, it is important to consider several key attributes. First and foremost is the material. High-quality rotors are typically made from food-grade stainless steel or other corrosion-resistant materials, ensuring they can withstand the rigors of continuous use and maintain hygiene standards. Suppliers should ensure that their rotors meet all industry regulations regarding food safety to avoid potential liabilities and recalls.

rotor for vacuum filler suppliers

Another crucial aspect is the rotor's design. A well-designed rotor will facilitate smooth and efficient product transfer, reduce product wastage, and minimize downtime due to maintenance issues. Suppliers should collaborate with manufacturers to understand the specific needs of the fillers they cater to, offering customizable options as necessary.

Moreover, rotors must also be tested for durability and performance. This includes evaluating their resistance to wear and tear, especially when handling abrasive or thick products. Suppliers who invest in rigorous testing processes will not only enhance their reputation but will also foster strong relationships with their clients, who depend on reliable equipment for their production processes.

Lastly, effective communication and support are essential in the supplier-client relationship. Suppliers should be prepared to offer comprehensive guidance regarding rotor selection, maintenance, and troubleshooting. Providing educational resources or training sessions for clients can further solidify trust and enhance customer satisfaction.

In conclusion, as the demand for efficient manufacturing processes continues to rise, the role of high-quality rotors in vacuum fillers cannot be understated. Suppliers who focus on the excellence of their rotor offerings will not only improve their competitive edge but also contribute to the overall success of their clients in the food and beverage industry. By emphasizing material quality, design innovation, durability, and customer support, suppliers can play a pivotal role in driving efficiency in production lines around the globe.

Latest news

-

[Product Name]-[Company Name]|[Core Function 1]&[Core Function 2]

NewsJul.13,2025

-

SmartFlow 3000 Series-Industrial Automation Solutions|AI Analytics&Energy Efficiency

NewsJul.13,2025

-

NextGen Equipment Series-IndustrialTech Solutions|Smart Automation&Real-Time Analytics

NewsJul.12,2025

-

Smart Irrigation System - Example Corp | Water Conservation, AI-Driven Efficiency

NewsJul.12,2025

-

Chicken breast meat slicer

NewsMar.07,2025

-

Meat Bowl cutter for LAB

NewsMar.07,2025