11월 . 23, 2024 03:23 Back to list

casing tying machine factories

The Rise of Casing Tying Machine Factories Revolutionizing Packaging Efficiency

In the fast-paced world of manufacturing and packaging, efficiency and accuracy are paramount. One of the key components in achieving this is the casing tying machine, which is crucial for securing products within their packages. As the demand for reliable and efficient packaging solutions rises, so too has the proliferation of casing tying machine factories across the globe.

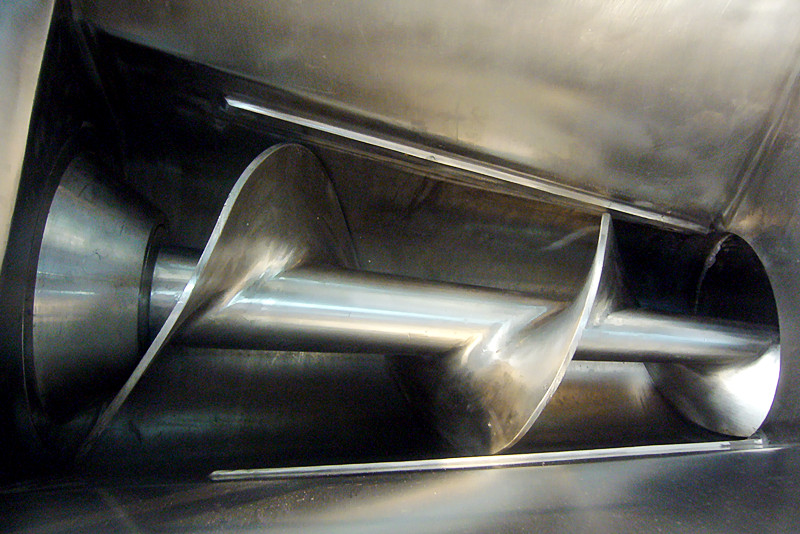

Casing tying machines are specifically designed to bind packages securely, ensuring that products remain intact during transportation and storage. This equipment is indispensable for a wide range of industries, including food production, pharmaceuticals, and consumer goods. The machines vary in complexity, from manual units that require human intervention to fully automated systems that can handle high volumes of packaging with minimal oversight.

Historically, packaging processes involved significant manual labor where workers would tie or strap packages by hand. This method, while effective to some extent, often resulted in inconsistencies and inefficiencies. As businesses sought to improve operational efficiency, the need for specialized machinery grew. In response, casing tying machine factories began to emerge, focusing on the design and production of equipment tailored to streamline packaging processes.

The modern casing tying machine factories utilize advanced technology to produce high-quality machines that offer several advantages. One of the primary benefits is the consistency in packaging. Automated tying machines can achieve uniform tension and placement, reducing the risk of damage and enhancing the overall appearance of the product. Moreover, these machines are designed to minimize waste by using materials efficiently, which corresponds to both economic savings and environmental sustainability.

casing tying machine factories

As the global market expands, casing tying machine factories are adapting to meet the diverse needs of various industries. Customization has become a key focus, with many factories offering bespoke solutions tailored to specific product types and packaging requirements. For instance, food manufacturers may require machines that comply with safety regulations, while electronics companies might need equipment that offers anti-static features. This flexibility has allowed factories to cater to a broader range of customers and broaden their market reach.

Additionally, the rise of e-commerce has significantly influenced the demand for casing tying machines. With more products being shipped directly to consumers, sturdy and secure packaging has become increasingly important. Factories are responding by innovating new machinery that enhances not only the tying process but also incorporates smart technology, enabling predictive maintenance and improving operational efficiency.

However, factory production of casing tying machines is not without its challenges. As the market competition intensifies, manufacturers must continually invest in research and development to stay ahead. This includes adopting cutting-edge materials, exploring automation technologies, and implementing sustainable practices in machine production. Furthermore, the global supply chain issues that have plagued industries in recent years pose additional challenges, compelling factories to develop more resilient sourcing strategies.

In conclusion, casing tying machine factories play a crucial role in the manufacturing and packaging sectors. With their ability to produce machines that enhance efficiency, ensure product safety, and cater to diverse market needs, these factories are at the forefront of the packaging revolution. As technology evolves and market demands change, the future of casing tying machine factories promises further innovations, ensuring they remain an integral part of the manufacturing landscape. Investing in these machines not only enhances productivity but also helps businesses meet the ever-increasing standards of quality and sustainability that consumers expect.