ມ.ກ. . 21, 2025 03:16 Back to list

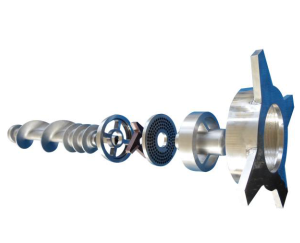

frozen meat flaker

Frozen meat flakers are essential tools in the food processing industry, specifically designed to transform blocks of frozen meat into manageable flakes for further processing. Understanding these machines and their significant impact on efficiency and product quality is crucial for businesses aiming to optimize their food production processes.

The credibility of using frozen meat flakers can be further reinforced through real-world experiences. Industry veterans acknowledge the remarkable improvements in efficiency that these machines bring. One plant manager noted a 40% increase in throughput after integrating frozen meat flakers into their production line, attributed to the reduction in manual handling and processing time. Additionally, consistent flake sizes improved product quality, meeting stringent market standards and enhancing customer satisfaction. Furthermore, aligning with food safety regulations, frozen meat flakers contribute significantly to maintaining strict hygiene practices. Their design often includes easy-to-clean surfaces and removable components, preventing contamination and ensuring compliance with the highest food safety standards. By incorporating regular maintenance schedules and sanitation protocols, businesses can bolster their reputation for safety and quality in the competitive food processing industry. Ultimately, relying on frozen meat flakers not only boosts operational productivity but also positions a company as a leader in innovative and efficient food processing solutions. Their ability to handle large volumes of frozen meat swiftly and hygienically ensures that businesses meet demanding production schedules without sacrificing the quality of their products. By investing in high-quality flakers and employing knowledgeable operators, food processing facilities can enhance their capabilities and remain competitive in a rapidly evolving market. In conclusion, frozen meat flakers serve as a cornerstone in modern food processing, offering unparalleled benefits in terms of efficiency, safety, and product quality. Their strategic implementation can drive significant improvements in production processes. As businesses continue to seek methods to refine their operations, frozen meat flakers represent a sound investment towards achieving superior results in the food industry.

The credibility of using frozen meat flakers can be further reinforced through real-world experiences. Industry veterans acknowledge the remarkable improvements in efficiency that these machines bring. One plant manager noted a 40% increase in throughput after integrating frozen meat flakers into their production line, attributed to the reduction in manual handling and processing time. Additionally, consistent flake sizes improved product quality, meeting stringent market standards and enhancing customer satisfaction. Furthermore, aligning with food safety regulations, frozen meat flakers contribute significantly to maintaining strict hygiene practices. Their design often includes easy-to-clean surfaces and removable components, preventing contamination and ensuring compliance with the highest food safety standards. By incorporating regular maintenance schedules and sanitation protocols, businesses can bolster their reputation for safety and quality in the competitive food processing industry. Ultimately, relying on frozen meat flakers not only boosts operational productivity but also positions a company as a leader in innovative and efficient food processing solutions. Their ability to handle large volumes of frozen meat swiftly and hygienically ensures that businesses meet demanding production schedules without sacrificing the quality of their products. By investing in high-quality flakers and employing knowledgeable operators, food processing facilities can enhance their capabilities and remain competitive in a rapidly evolving market. In conclusion, frozen meat flakers serve as a cornerstone in modern food processing, offering unparalleled benefits in terms of efficiency, safety, and product quality. Their strategic implementation can drive significant improvements in production processes. As businesses continue to seek methods to refine their operations, frozen meat flakers represent a sound investment towards achieving superior results in the food industry.

Latest news

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.

NewsAug.13,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery | Automated Sausage Production&Precision Cutting

NewsAug.13,2025

-

Commercial Brine Injector: Flavor & Tenderize Meat Efficiently

NewsAug.13,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd. | Precision & Efficiency

NewsAug.13,2025

-

Pneumatic Clipping Machine - Shijiazhuang Bossin Machinery Equipment Co., Ltd.|Precision Sausage Production,Cost-Effective Solutions

NewsAug.12,2025

-

Pneumatic Clipping Machine-BoSSIN|Efficiency,Precision

NewsAug.12,2025