ພ.ຈ. . 25, 2024 07:08 Back to list

Factory Production of Mechanical Meat Tenderizers for Enhanced Culinary Experience

The Rise of Machine Meat Tenderizer Factories Revolutionizing the Culinary Industry

In recent years, the meat processing industry has witnessed a significant transformation, driven by technological advancements and increasing consumer demand for quality food products. One of the most notable innovations in this sector is the machine meat tenderizer, which has revolutionized the way meat is prepared, processed, and ultimately enjoyed by consumers worldwide. This article will delve into the rise of machine meat tenderizer factories, exploring their technology, benefits, and impact on the culinary landscape.

Background and Evolution

Historically, the process of tenderizing meat was labor-intensive, relying mainly on manual methods. Chefs and butchers employed techniques such as pounding, marinating, and slow cooking to achieve the desired tenderness. However, these methods often resulted in inconsistent quality and variable outcomes. The emergence of machine meat tenderizers marked a turning point in the industry, allowing for more uniform results and greater efficiency in meat preparation.

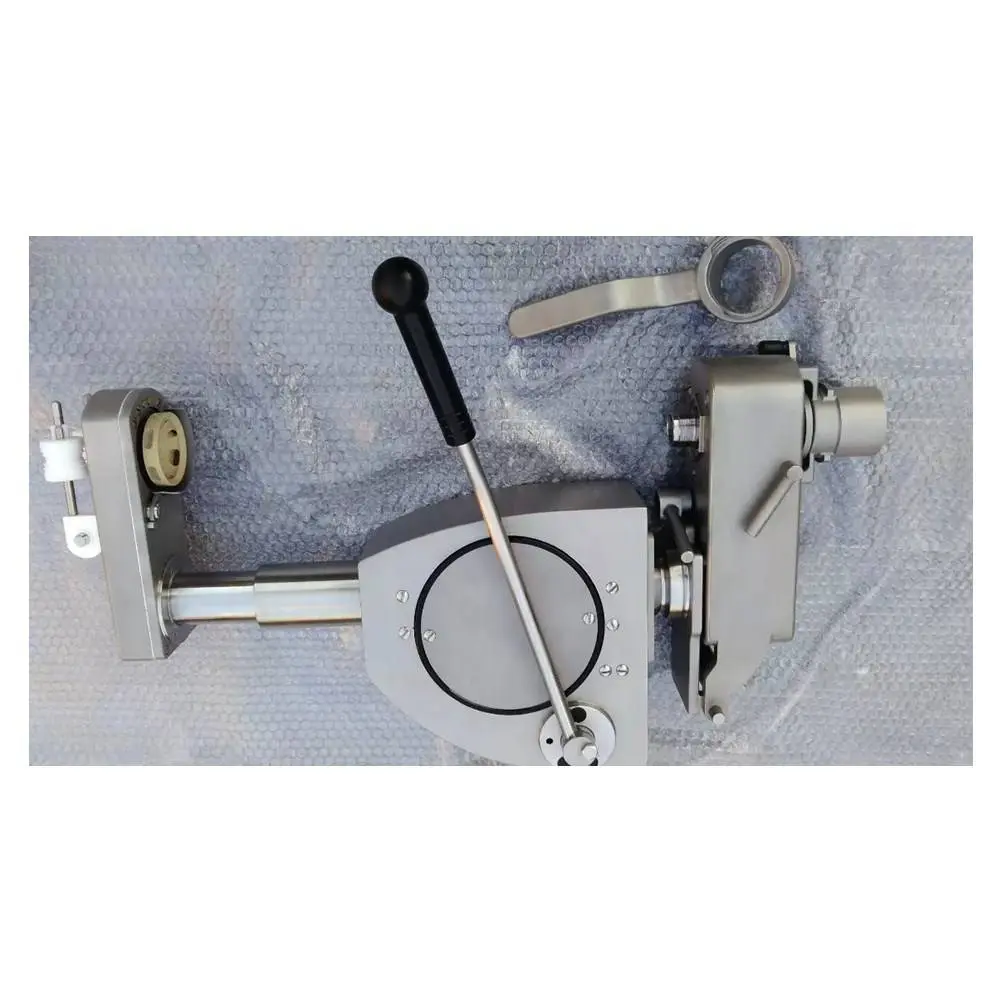

Machine meat tenderizers employ various mechanisms, including blades, rollers, and needles, to break down the muscle fibers in meat. These machines can significantly reduce the time and effort involved in tenderizing, making them indispensable in commercial kitchens and meat processing plants. As demand for tender cuts of meat continues to rise, factories specializing in the production of these machines have proliferated around the globe.

Technological Advancements

Modern machine meat tenderizers are a marvel of engineering, featuring sophisticated designs that cater to both small-scale and large-scale meat processing operations. These machines can adjust to various types of meat, including beef, pork, poultry, and even game meats. Recent innovations focus on enhancing durability, reducing noise levels, and increasing the efficiency of the tenderizing process.

One significant advancement is the use of automation and robotics in machine meat tenderizer factories. Automated systems can handle multiple tasks, from loading and unloading meat to monitoring tenderness levels in real-time. This not only speeds up production but also ensures that safety and hygiene standards are consistently met.

machine meat tenderizer factory

Another exciting development is the integration of smart technology in these machines. Some manufacturers have introduced IoT (Internet of Things) capabilities, allowing operators to monitor machine performance remotely and receive alerts for maintenance needs. This feature enhances operational efficiency and prolongs the lifespan of the machines, ultimately benefiting both manufacturers and users.

Benefits of Machine Meat Tenderizers

The primary advantage of machine meat tenderizers is their ability to produce consistently tender meat, which is especially important in the competitive food market. Chefs and restaurant owners can rely on these machines to deliver products that meet customers' expectations, thus enhancing overall dining experiences. Furthermore, when meat is tenderized uniformly, it cooks more evenly, resulting in better flavor and texture.

From a business perspective, utilizing machine meat tenderizers can lead to cost savings and increased productivity. With reduced labor requirements and faster processing times, meat producers can allocate resources more effectively, ultimately improving their bottom line. Additionally, the ability to tenderize meat more efficiently means that manufacturers can meet rising consumer demands without compromising quality.

Environmental Considerations

As the world becomes increasingly conscious of sustainability, machine meat tenderizer factories are also assessing their environmental impact. Many manufacturers are exploring eco-friendly materials and energy-efficient designs to minimize waste during production. Additionally, using these machines can help reduce food waste by maximizing the use of all parts of the animal, making the meat processing industry more sustainable overall.

Conclusion

The rise of machine meat tenderizer factories marks a significant evolution in the meat processing sector. By combining technological advancements with a focus on quality and efficiency, these factories have transformed how meat is prepared and consumed. As the culinary landscape continues to evolve, the role of machine meat tenderizers is likely to grow, laying the foundation for future innovations in food preparation and production. Ultimately, these machines offer a bright outlook for the industry, ensuring that consumers can enjoy tender, delicious meat while benefiting from sustainable practices.